Preparation method of dye composition for dyeing of fiber material

A technology of dye composition and fiber material, applied in the field of dye composition, can solve problems such as poor stability and low solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of a dye composition, comprising the steps of:

[0024] Fully pulverize the three kinds of dyes, Dekaisu Black B 250KG, Reactive Orange G 80KG, and Reactive Yellow 40KG, and then add them to a 2000L blending tank in sequence, then add 600KG of purified water, 9.45KG of dispersant NNO, 0.9KG of EDTA, phosphoric acid 1.5KG of sodium dihydrogen, 13.05KG of propylene glycol, 2.7KG of auxiliary agent M, and 2.4KG of auxiliary agent N were fully stirred for 2 hours, and after confirming that the stirring was uniform, samples were taken, and after passing the inspection, they were packaged to obtain a dye liquid composition of about 1000kg.

Embodiment 2

[0032] A preparation method of a dye composition, comprising the steps of:

[0033] Fully pulverize the three kinds of dyes, Dekaisu Black B 685KG, Reactive Orange G 280KG, and Reactive Yellow 145KG, and then add them to a 4000L blending tank, then add 1800KG of purified water, 28.35KG of dispersant NNO, 2.7KG of EDTA, phosphoric acid 4.5KG of sodium dihydrogen, 39.15KG of propylene glycol, 8.1KG of auxiliary agent M, and 7.2KG of auxiliary agent N were fully stirred for 2 hours. After the stirring was confirmed, samples were taken, and after passing the inspection, they were packaged to obtain a dye liquid composition of about 3000kg.

Embodiment 3

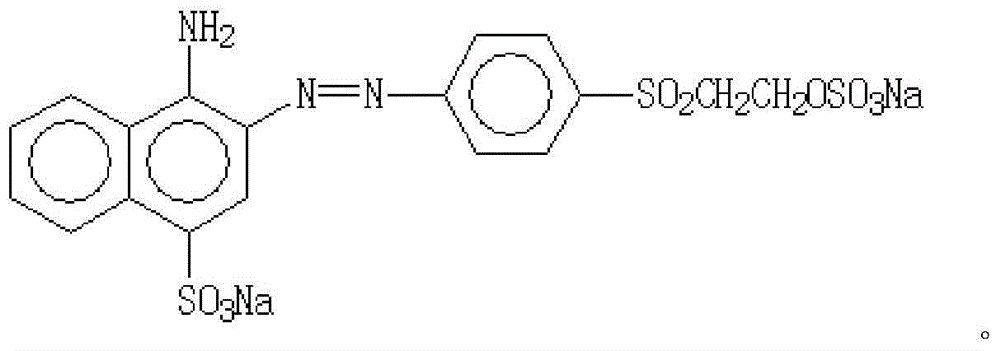

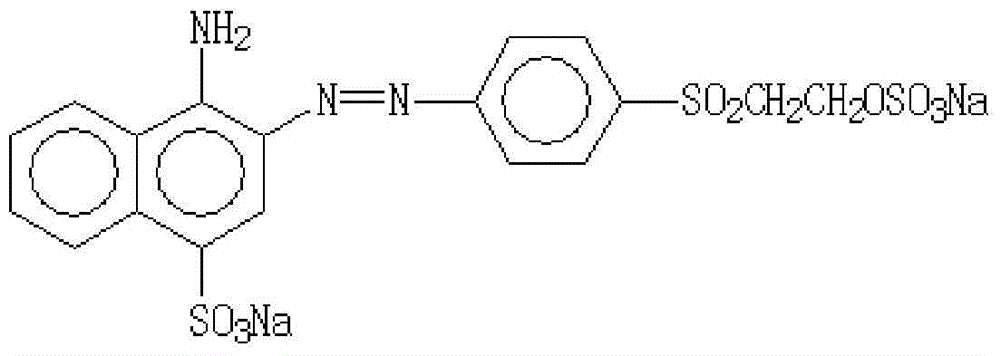

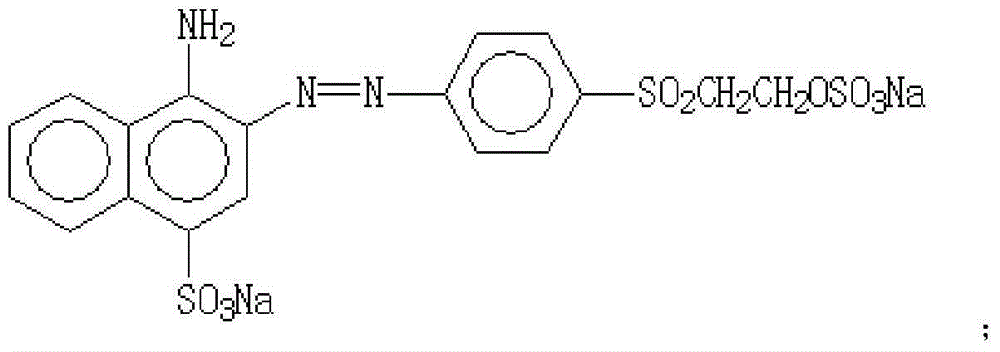

[0040] The preparation method of active orange G comprises the steps:

[0041]

[0042] Add 2500L of water to a 10-ton reaction tank, add 292KG of para-ester for beating for 2 hours, after beating, add 150KG of hydrochloric acid to the reaction tank, add 2000kg of ice, cool down to 0-5°C, and quickly add 30% sodium nitrite The solution was diazotized for 2 hours. During the diazotization reaction, always keep excess nitrous acid (with starch potassium iodide test paper). After the diazotization reaction is completed, remove excess nitrous acid with sulfamic acid.

[0043] Add 326KG 1-naphthylamine-4-sodium sulfonate to the diazonium salt, use soda ash solution to adjust the pH of the reaction solution to 5.5-6.0 and react for 2 hours to check whether the diazonium salt is excessive. If it is excessive, add 1-naphthylamine- The 4-sodium sulfonate reacted after the diazonium salt disappeared completely. That is, Active Orange G is produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com