Method for inserting a coil in a polyphase rotating electrical machine stator, and associated stator

A technology of coil insertion and electric motors, applied in the manufacture of motor generators, prefabricated windings embedded in motors, electric components, etc., can solve problems such as damage to product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

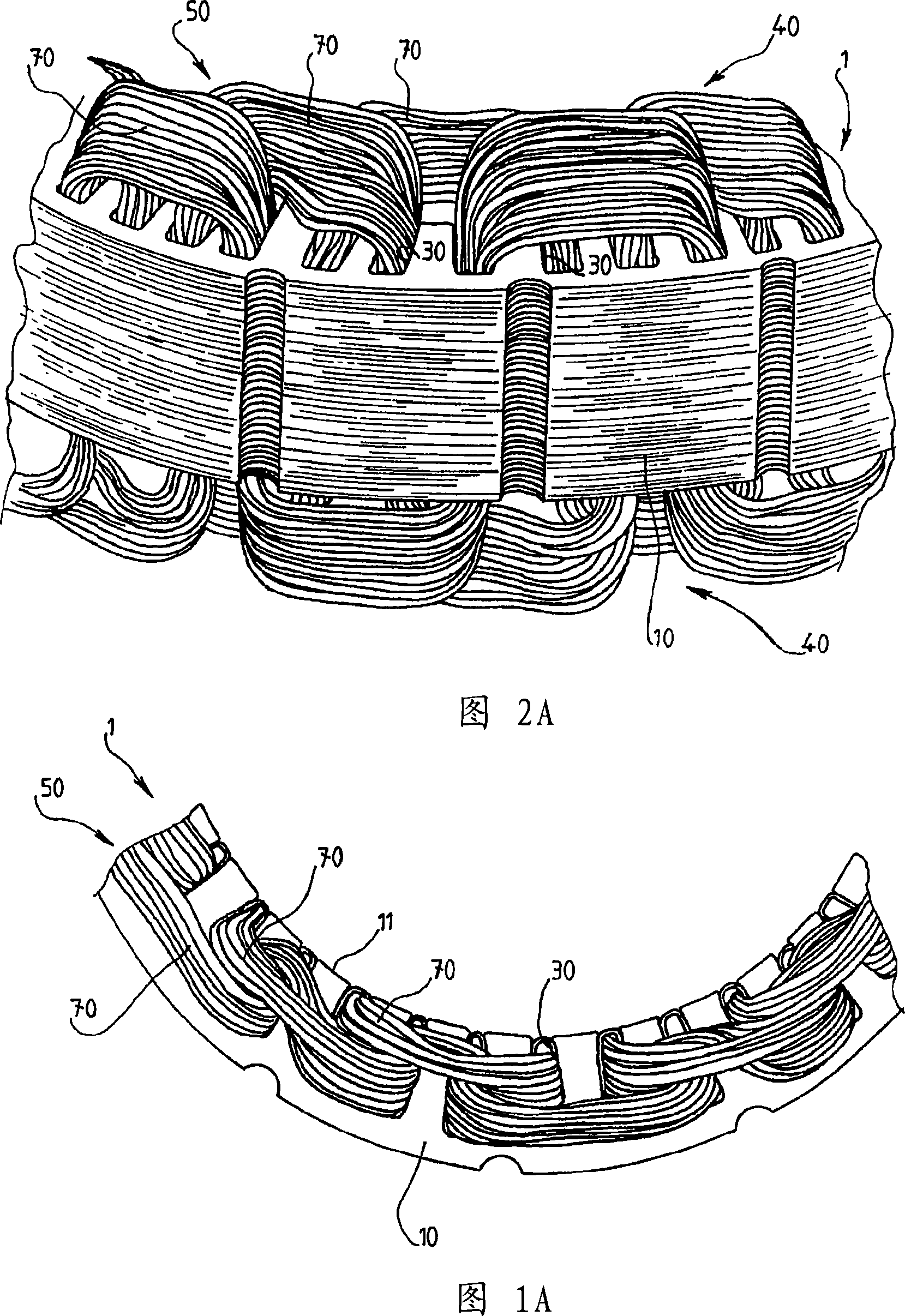

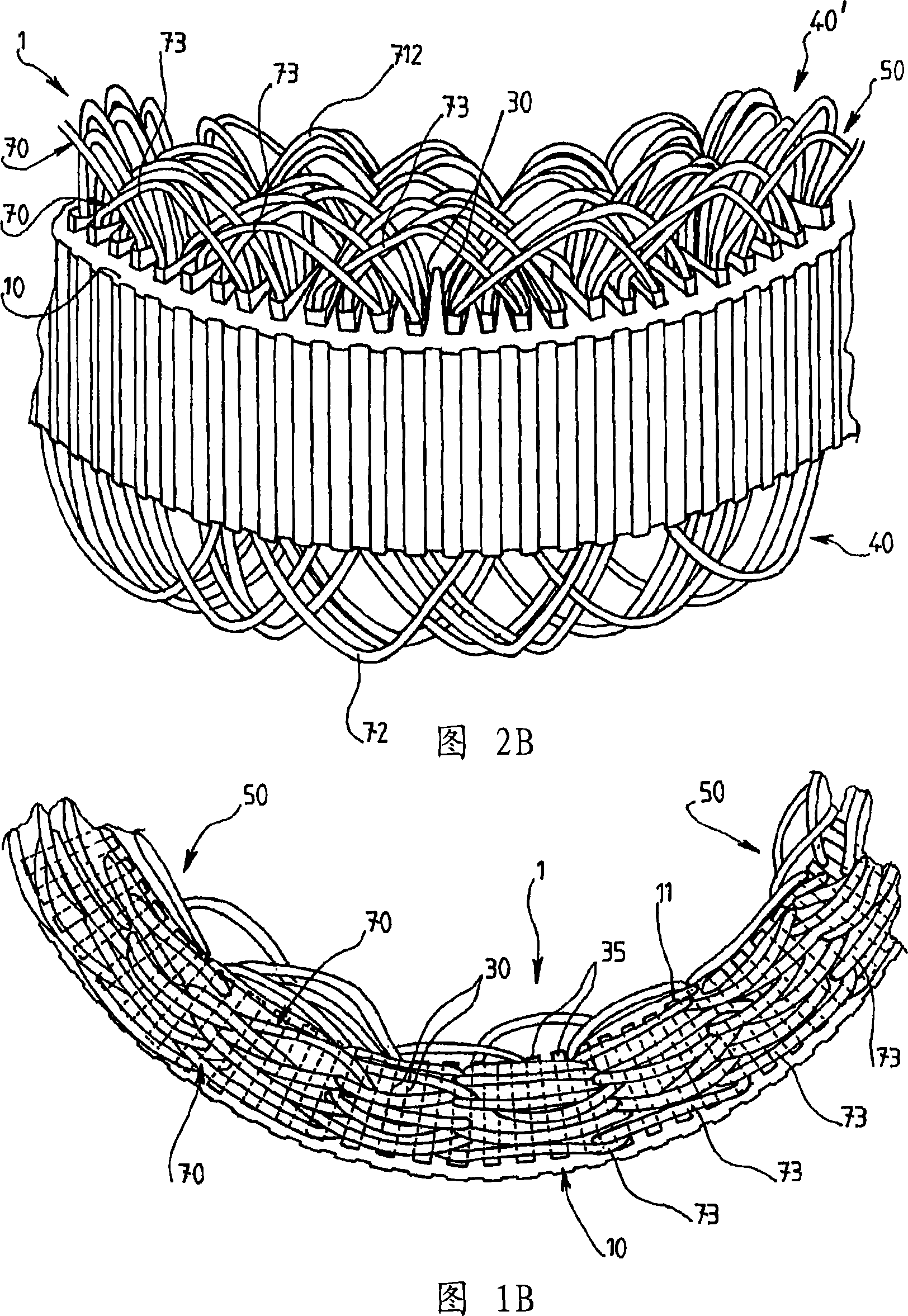

[0087] The insertion method is adapted to the sawtooth coil 50 to be inserted into the generator or motor vehicle generator / starter stator 1 .

[0088] The stator 1 comprises a cylindrical sheet metal pack 10 ( FIG. 10 ) having an axial axis of symmetry 20 ; and an axial recess 30 formed on the radially inner surface 11 of the sheet metal pack 10 . The recesses 30 are separated from each other by axial ribs 35 called teeth ( FIGS. 11A , 11B ).

[0089] These recesses 30 pass axially through the sheet metal pack 10 with the central hole, since they extend over the entire axial length of the sheet metal pack 10 and are radially open on the inside and at two opposite axial ends.

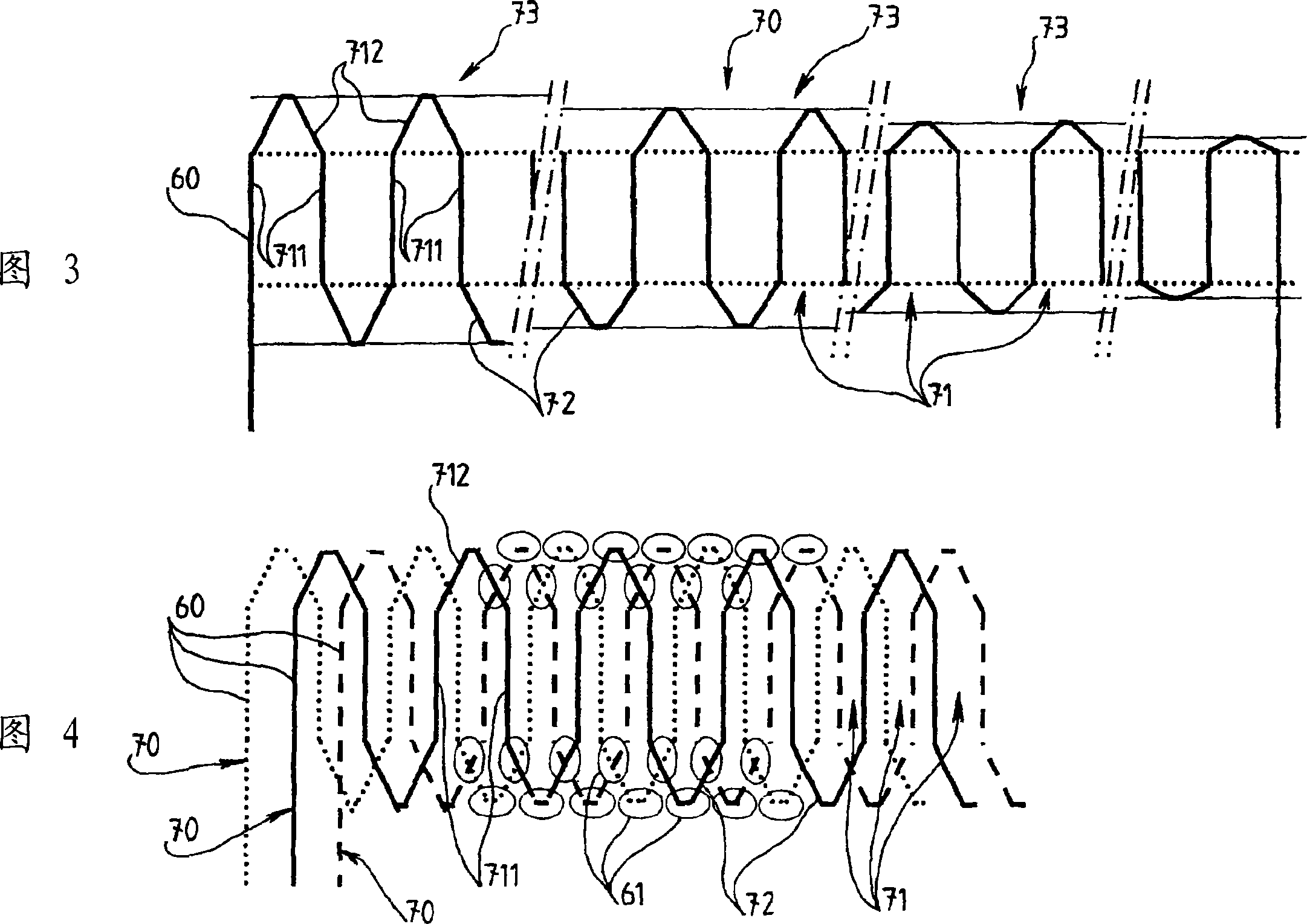

[0090] Coil 50 includes a plurality of phase windings 70, each winding including at least one conductive continuous wire 50 (Figs. 3 and 4). The cable is for example made of copper covered with an insulator such as enamel.

[0091] The phase windings 70 typically comprise a single wire, or two paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com