Manufacturing method of circuit board encapsulated by accumulation circuit

A circuit board manufacturing and integrated circuit technology, which is applied in chemical/electrolytic methods to remove conductive materials, printed circuit components, and secondary processing of printed circuits, etc. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The invention provides a circuit board manufacturing method applied to integrated circuit packaging.

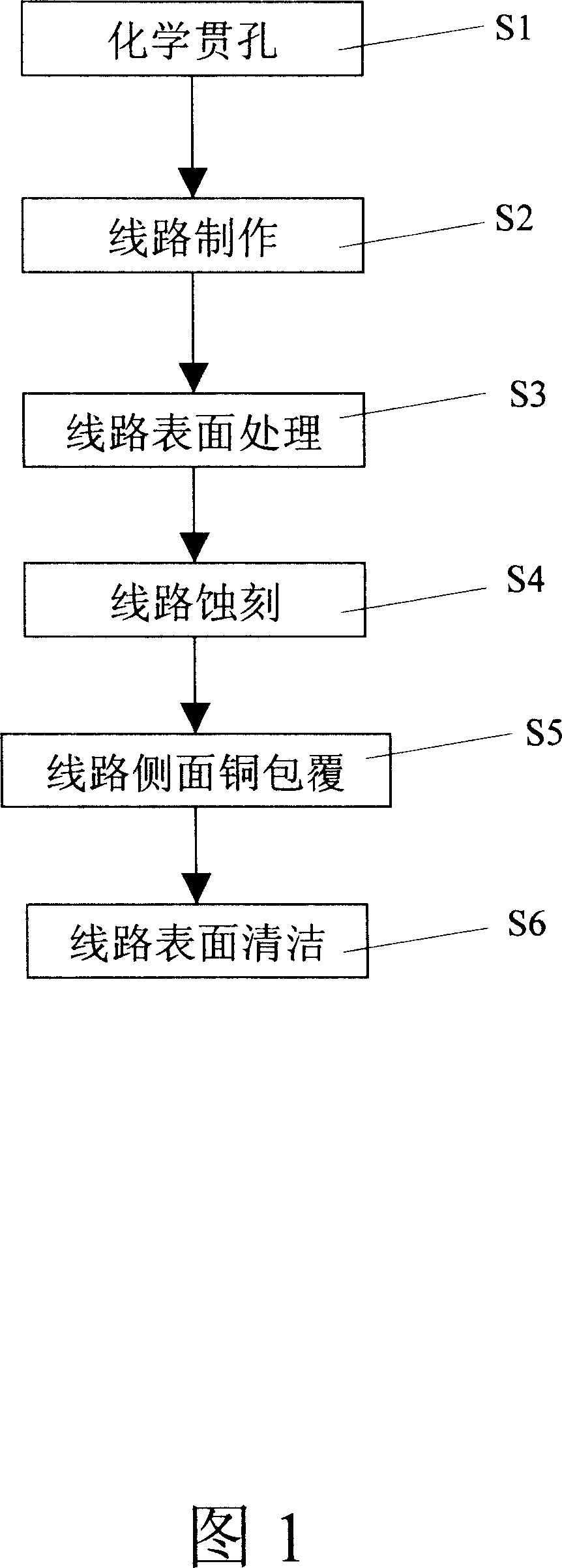

[0043] First, please refer to Figure 1, the steps include:

[0044] Step 1 (S1), chemical through hole: make a chemical through hole (PTH) on the copper circuit board to make the upper and lower copper surfaces conductive;

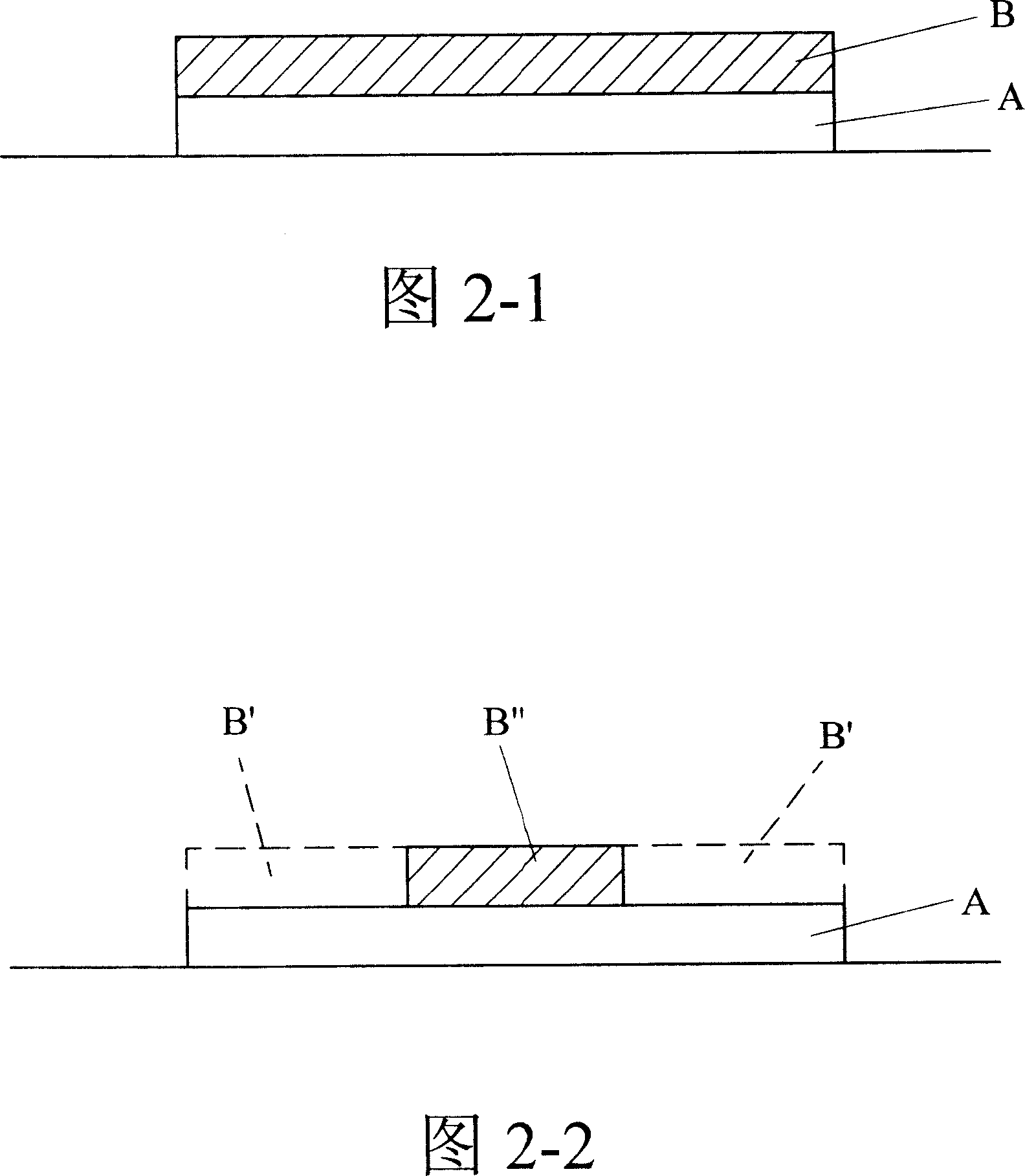

[0045] Step 2 (S2), circuit production: use liquid ink or photosensitive ink to form a circuit through the film and light source exposure principle (as shown in Figure 2-1, the copper layer is A, and the ink is B), and then remove it chemically Ink on the surface of the circuit to expose the copper layer on the surface of the circuit (as shown in Figure 2-2, the removed ink is B', the remaining ink B", and the underlying copper layer A can be exposed after ink B' is removed) .

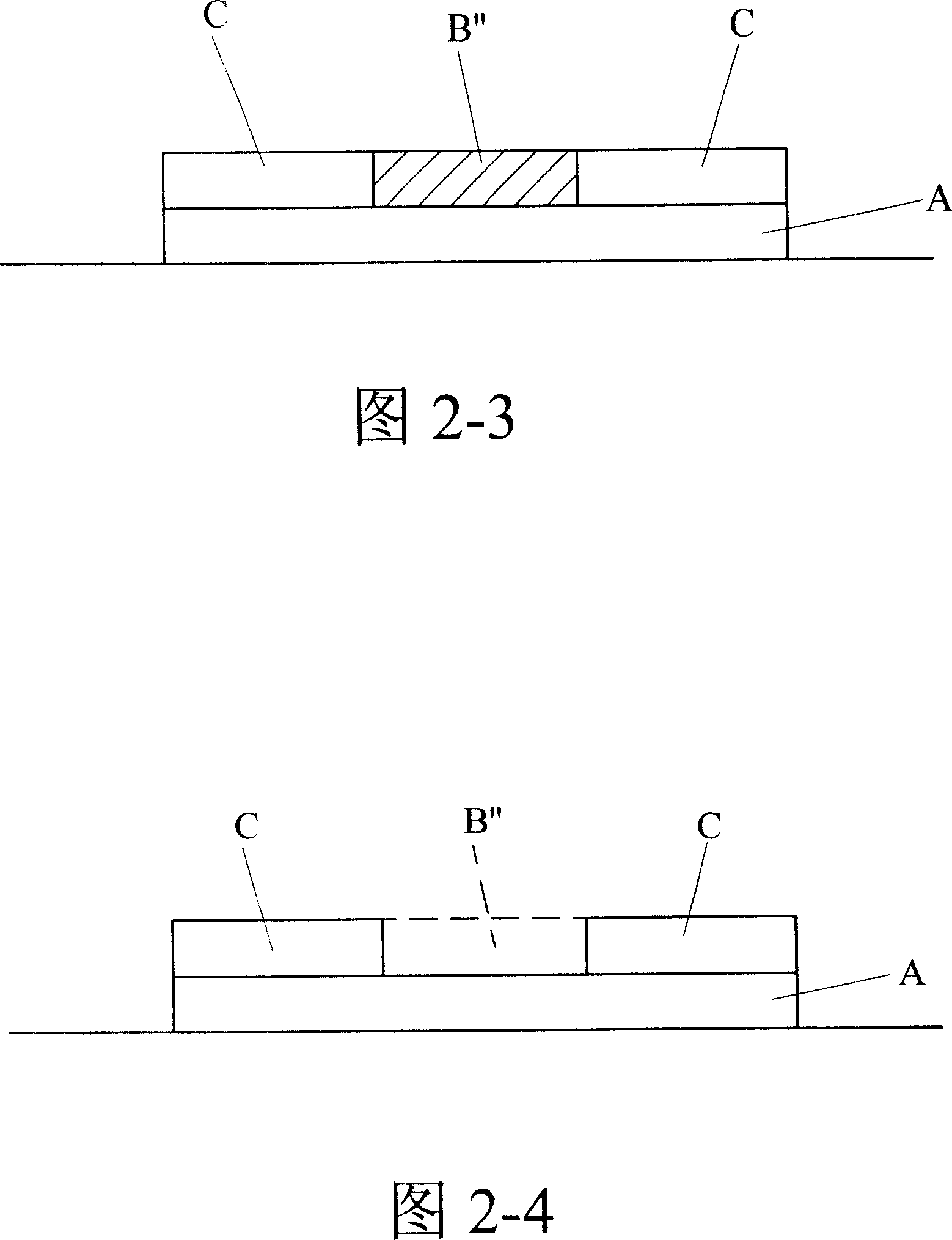

[0046] Step 3 (S3), circuit surface treatment: after removing the remaining ink on the circuit surface, the exposed copper surface is plated with a metal layer conforming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com