Rotary knife with blade bushing

A technology of blades and knives, which can be used in slaughtering accessories, boning shears/bone crushers, metal processing, etc., and can solve problems such as wear and defects at the blade bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

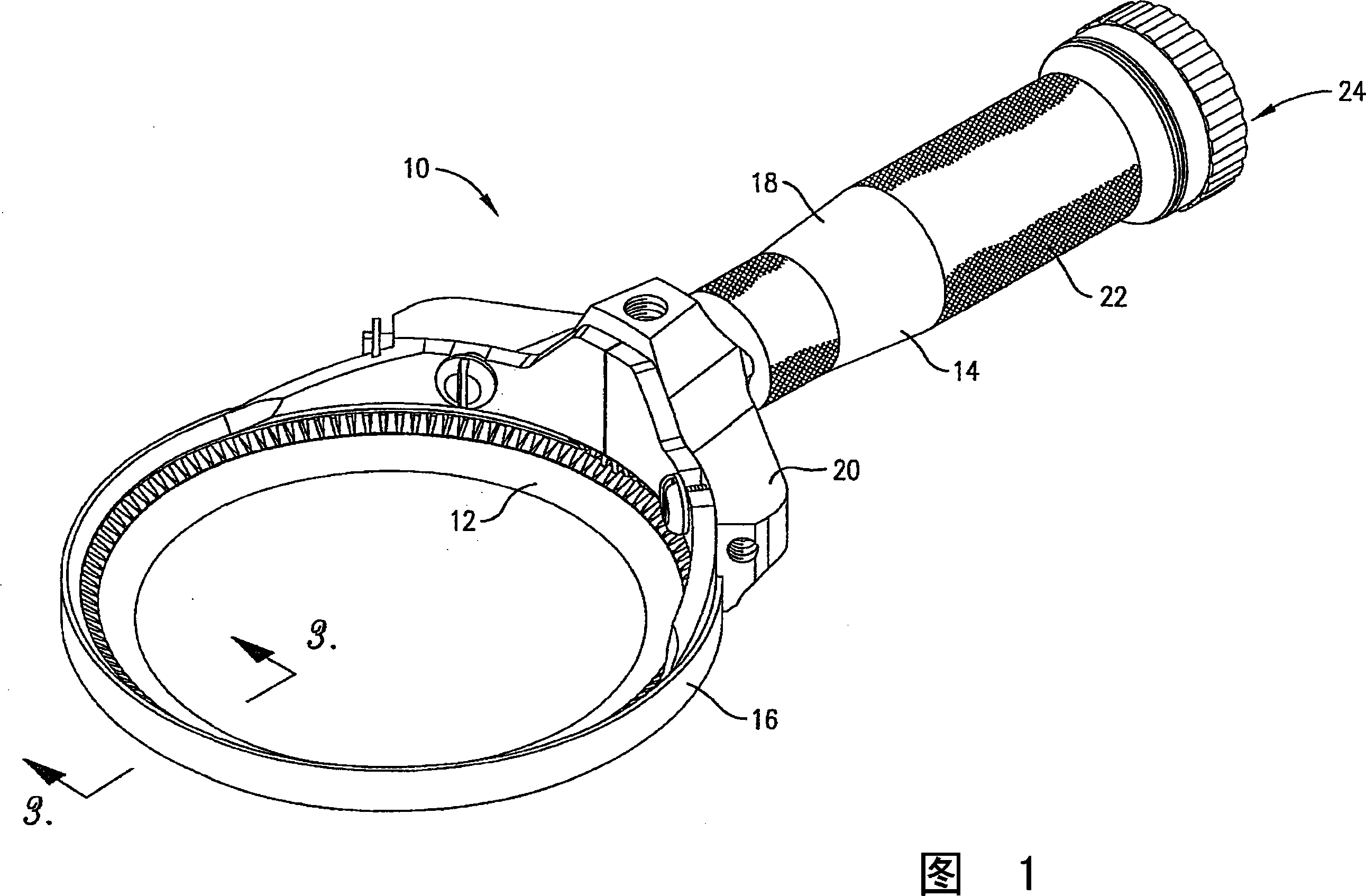

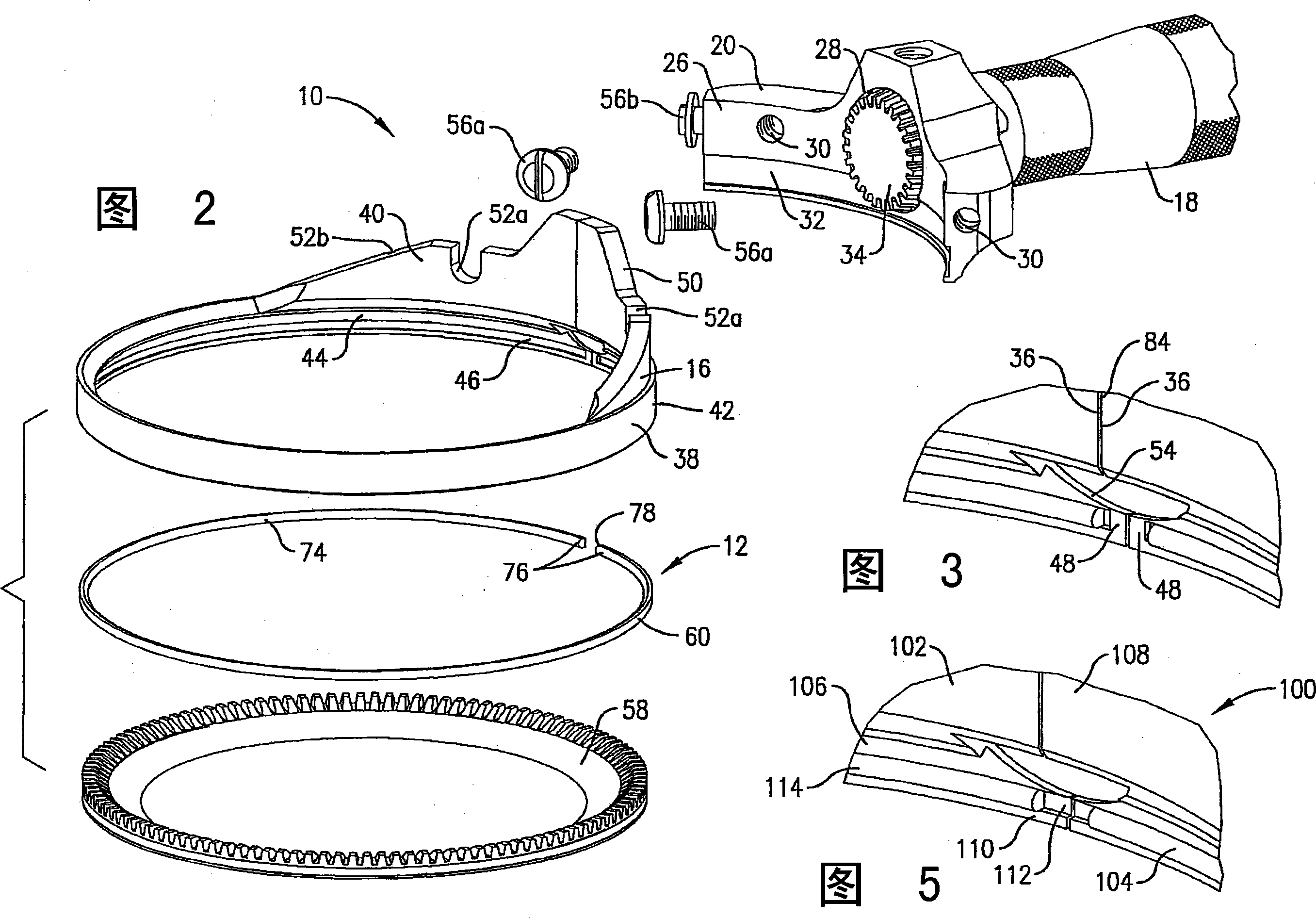

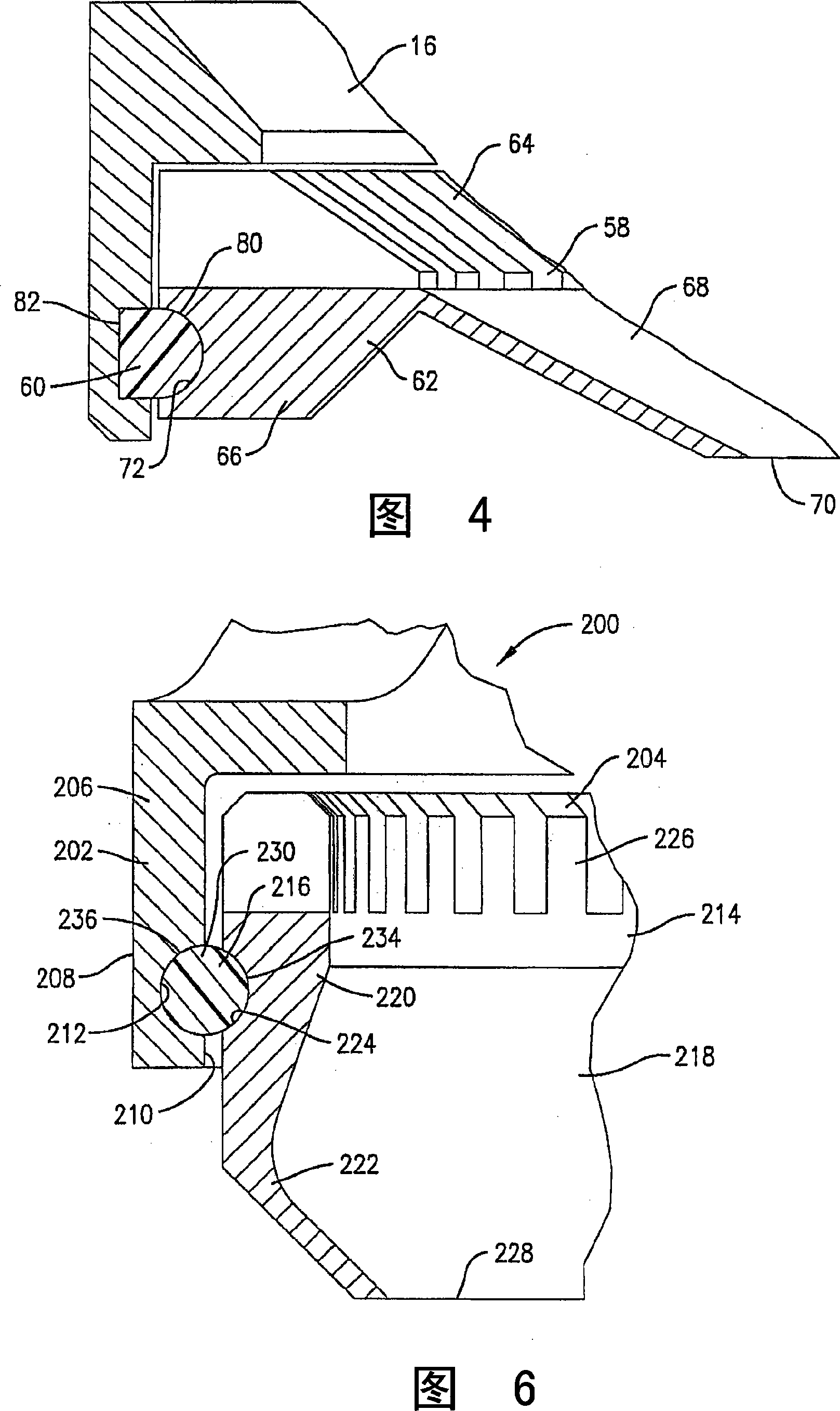

[0016] As shown in FIG. 1, the rotary knife 10 shown therein is particularly suitable for use in handling animal carcasses in an animal slaughterhouse, although other applications of the knife are well within the scope of the present invention. The rotary cutter 10 shown preferably includes an annular rotary blade assembly 12 . The rotary cutter 10 shown is preferably pneumatically driven by a compressed air source (not shown), such as an air compressor. However, the principles of the present invention are equally applicable to rotary knives driven by an alternative external power source, which transmits energy either hydraulically or electrically. The rotary knife 10 generally includes a handle 14 , a blade housing 16 , and a rotary blade assembly 12 .

[0017] Referring to FIGS. 1 and 2 , the handle 14 includes a handle housing 18 and a bracket 20 . The handle housing 18 includes a knurled exterior surface 22 for enhancing friction between a user's hand and the handle hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com