Card and its printing process

A card and silk screen printing technology, applied in the field of card and its production, can solve the problems of low attractiveness and low collection value, and achieve the effect of good hand feeling and strong sense of fashion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

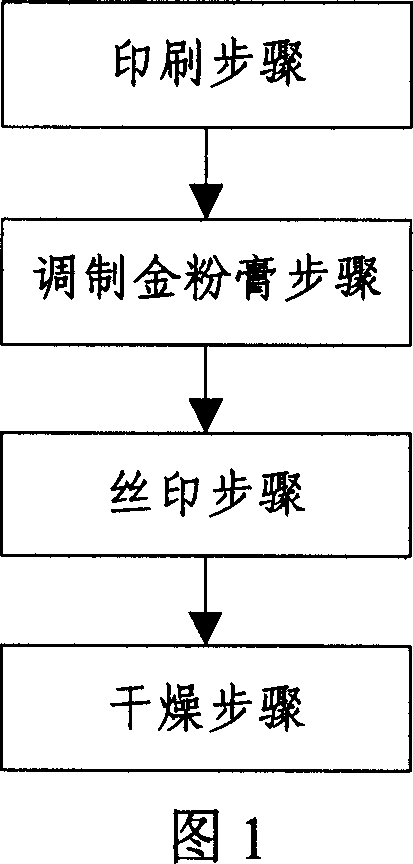

[0013] As shown in Figure 1, the present invention provides a kind of card printing method, and it mainly comprises the following steps:

[0014] A printing step of printing the selected pattern on the surface of the card body;

[0015] In the step of preparing gold powder, mix the gold powder and transparent ink according to a certain ratio and mix thoroughly to form a gold powder paste;

[0016] In the silk screen printing step, the adjusted gold powder paste is screen printed on the pattern surface of the card body to form a pattern-shaped convex gold powder layer;

[0017] Drying step to remove moisture and allow the glue to dry.

[0018] Wherein, the main body of the card is made of paper or plastic, and the printed patterns can be various beautiful and / or commemorative patterns, and can be various pictures, photos, etc.

[0019] When preparing the gold powder paste step, the mass ratio range of gold powder to ink is preferably (0.5-1): 1, generally 0.75: 1, and the fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com