Roller washing machine

A drum-type washing machine and machine body technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of reduced anti-vibration effect, fatigue damage, breakage, etc., and achieve shortened molding time, simplified mold structure, and production The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

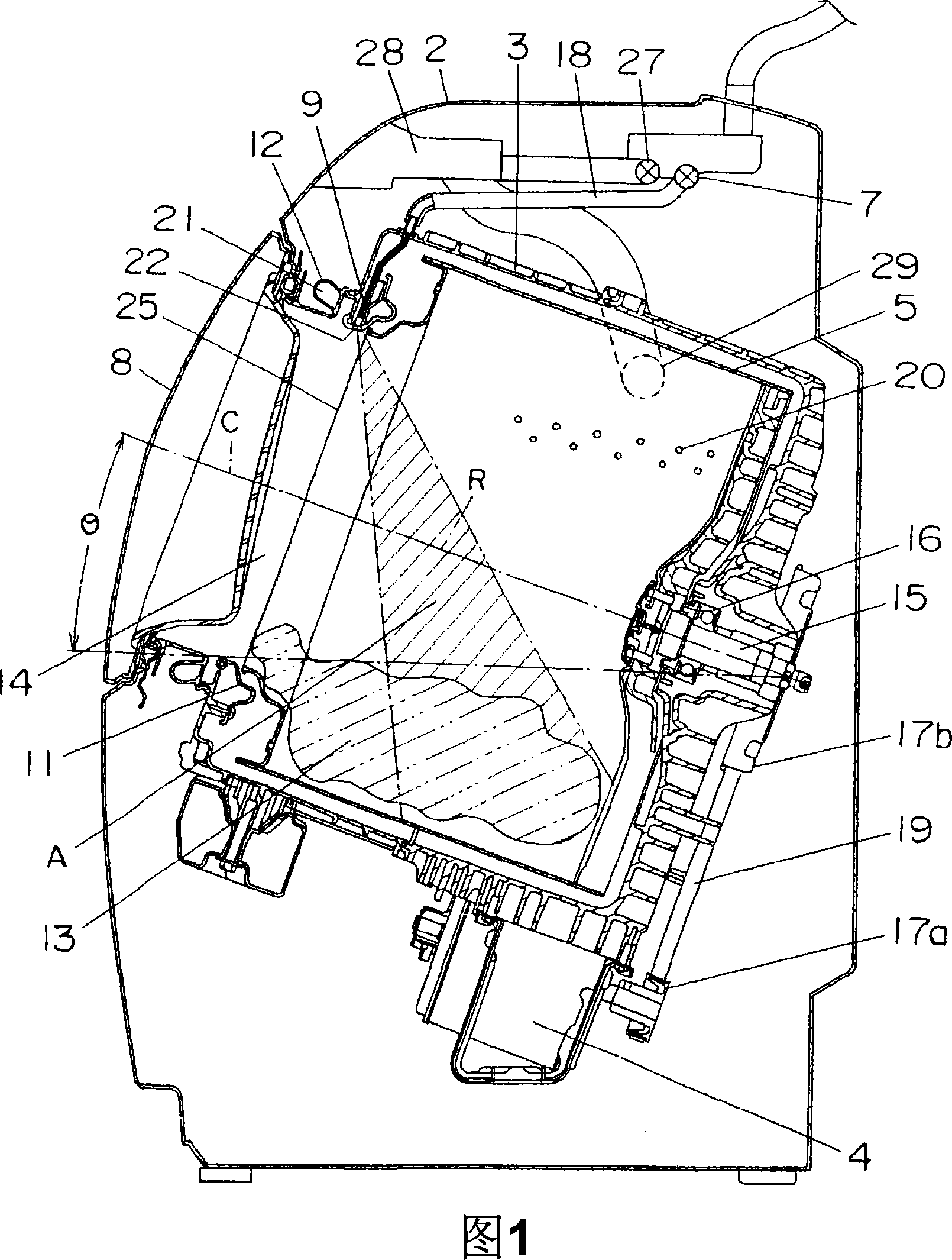

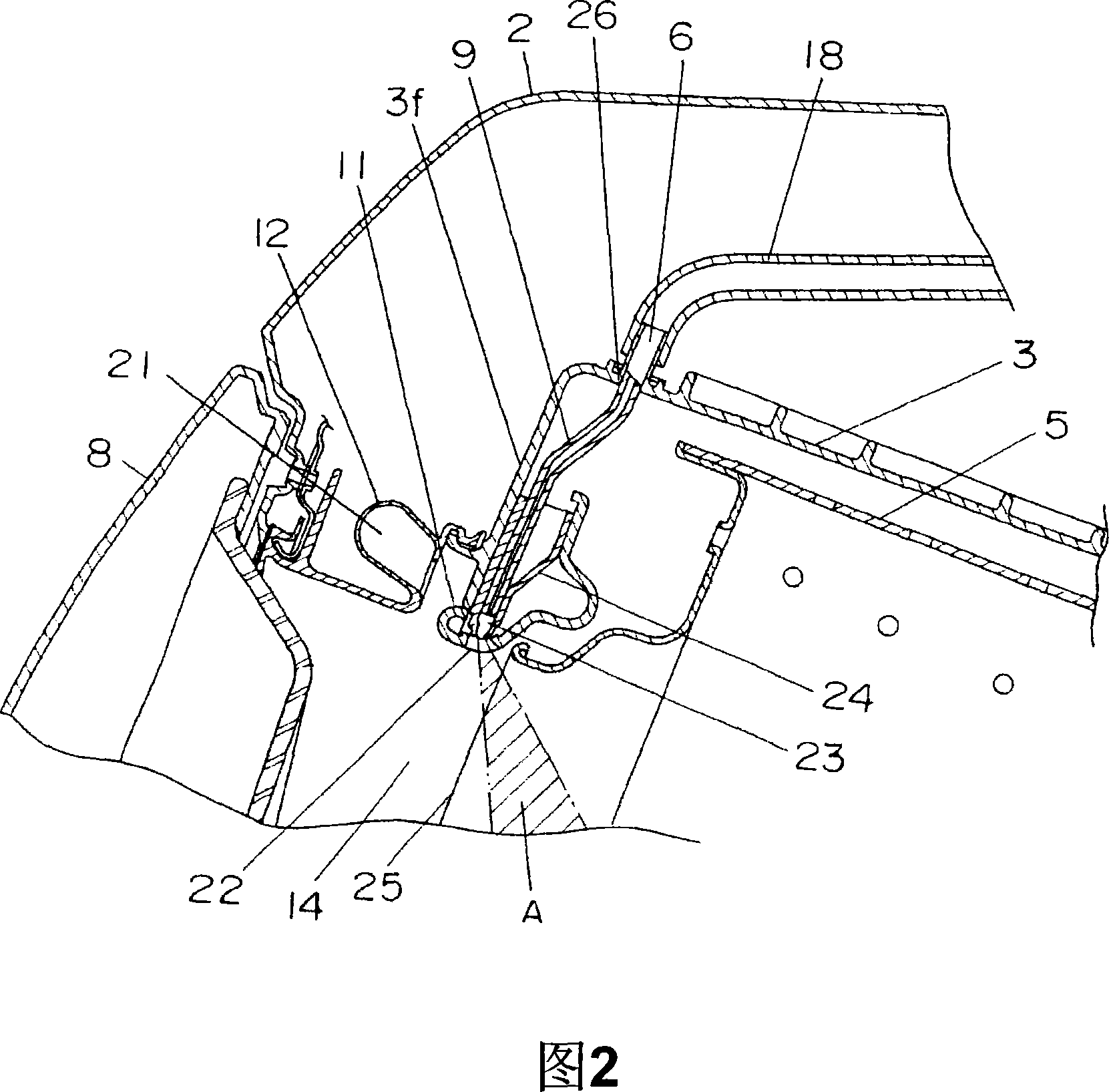

[0028] 1 is a cross-sectional view of a front-loading washing machine in a first embodiment of the present invention, and FIG. 2 is a partial schematic cross-sectional view of the front-loading washing machine.

[0029] As shown in Figure 1, in the drum type washing machine of the above-mentioned embodiment of the present invention, the washing machine body 2 is provided with a rotating drum 5 with a circular clothes inlet 25 in the front and a water tub 3 for accommodating the rotating drum 5. , and the rotating drum 5 and the water tub 3 are inclined upwards from the horizontal direction at an angle θ; the front of the washing machine body 2 is also inclined to form an inclined surface, which constitutes a washing machine that is easy to insert / take out from the door 8 into the rotating drum 5 Inclined drum type drum washing machine.

[0030] The arrangement of the rotating drum 5 in the water tub 3 is as follows: the opening side of the bottomed cylinder is located on the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap