Washing dryer

A washing-drying and drying technology, which is applied to washing devices, other washing machines, household dryers, etc., can solve the problems of difficulty in compactness, reduced degree of freedom, and inability to expand the diameter of the air supply fan, and achieves large-scale, high-speed transmission. The effect of increased wind power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

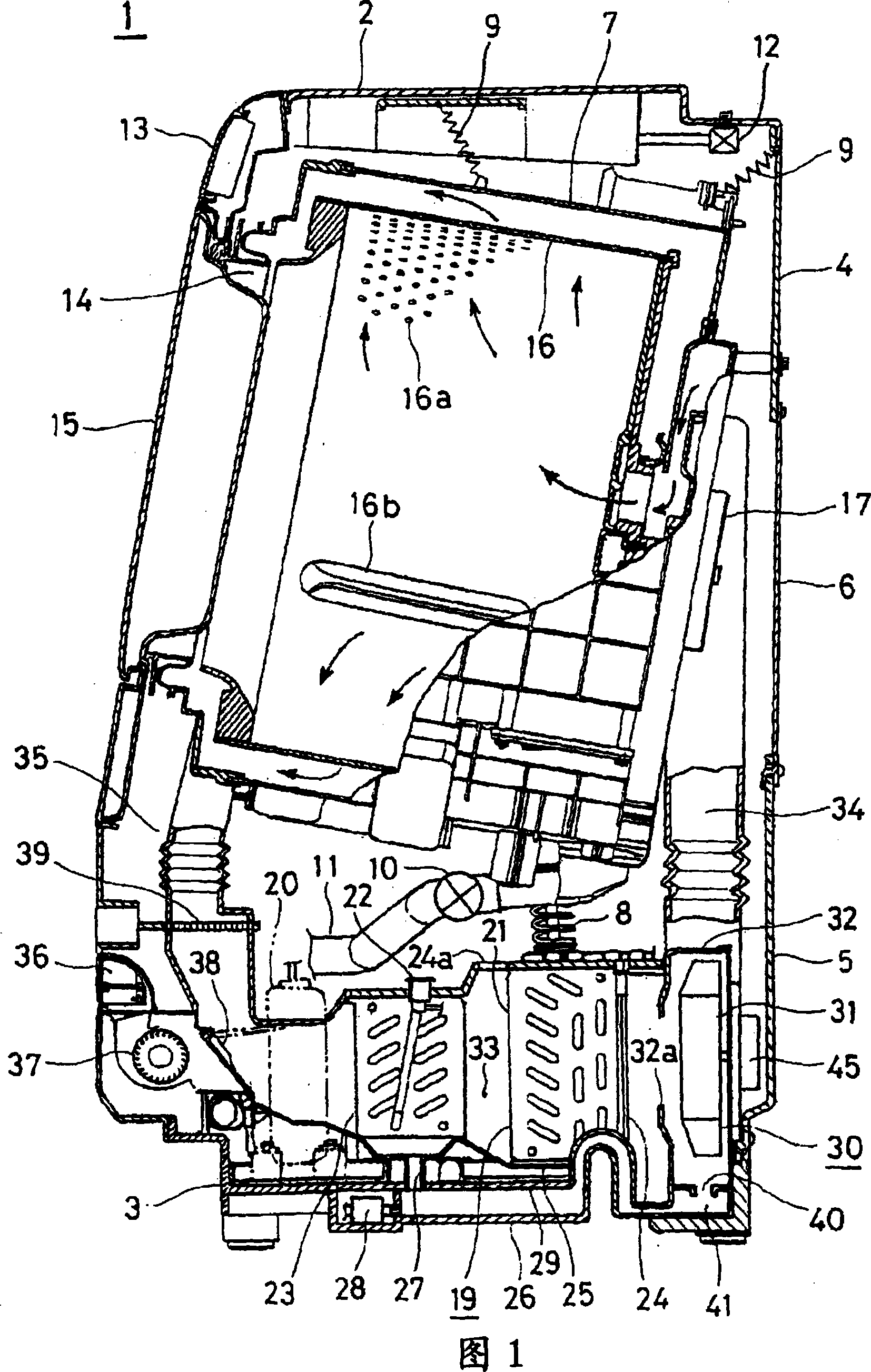

[0027] One embodiment of the present invention will be described below based on the drawings. In Fig. 1, a longitudinal sectional side view of the whole product of the drum type washing and drying machine 1 is shown. Body 2. The lower surface of the casing 2 is covered with a relatively thick disc-shaped bottom plate 3 formed of polyethylene resin (polypropylene resin) or the like. In addition, on the open back surface, an upper frame (upperframe) 4 made of a steel plate as a rigid body and The bottom plate 3 is arranged between the left and right side plates, thereby maintaining the rigidity of the casing 2, the back side between the upper frame and the bottom plate 3 is open, and a lower frame (lower frame) 5 made of a detachable steel plate and Covered by a thin-walled back cover 6 for inspection.

[0028] A water tank 7 is arranged inside the casing 2 . The water tank 7 is in the shape of a horizontal cylinder with the back closed, and its bottom is supported by a pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com