Magnetron

A magnetron and tube shaft technology, applied in the field of magnetron, can solve the problems of increasing the working space, cost increase, and unavoidable cost increase, etc., and achieve the effect of miniaturization and improvement of oscillation output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

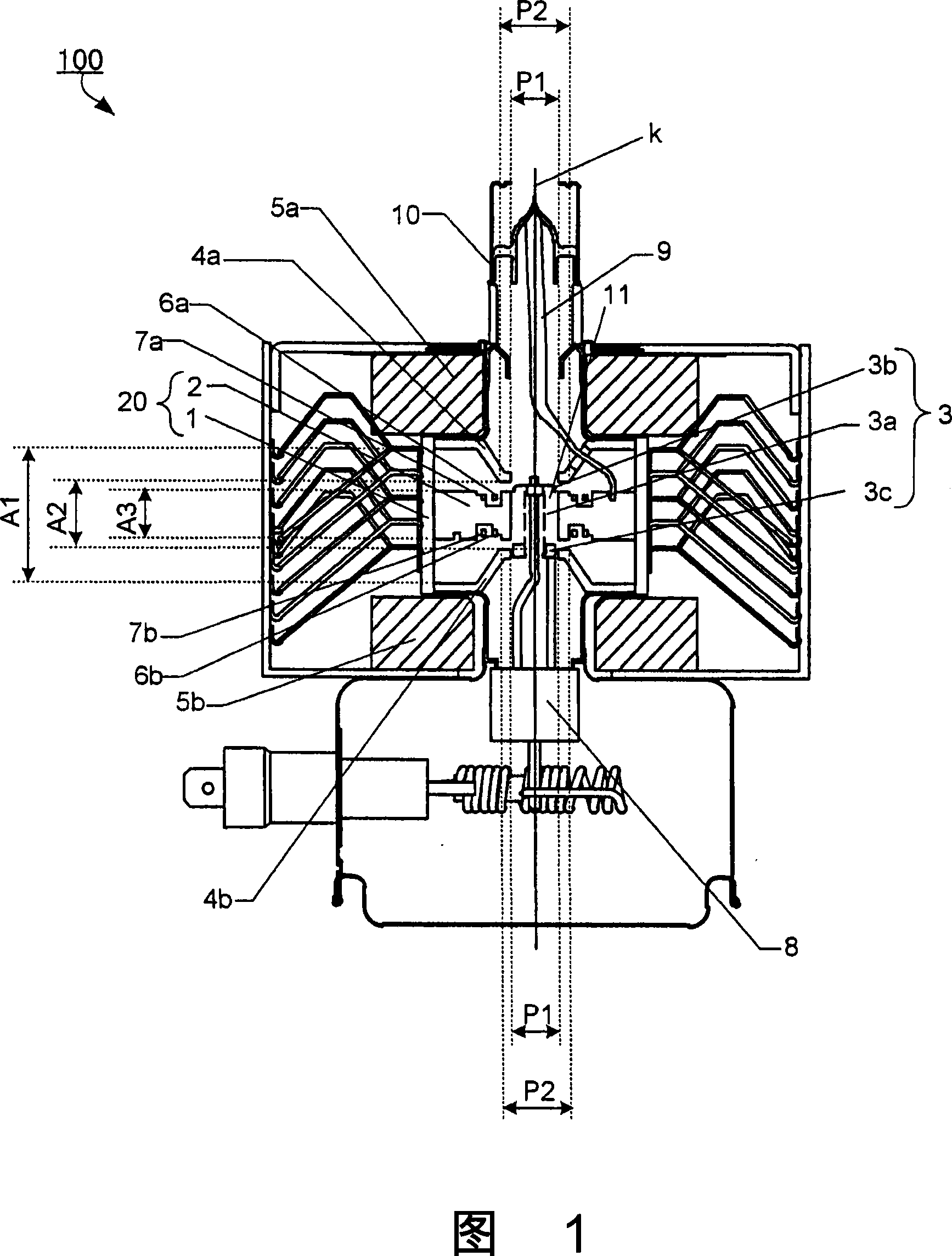

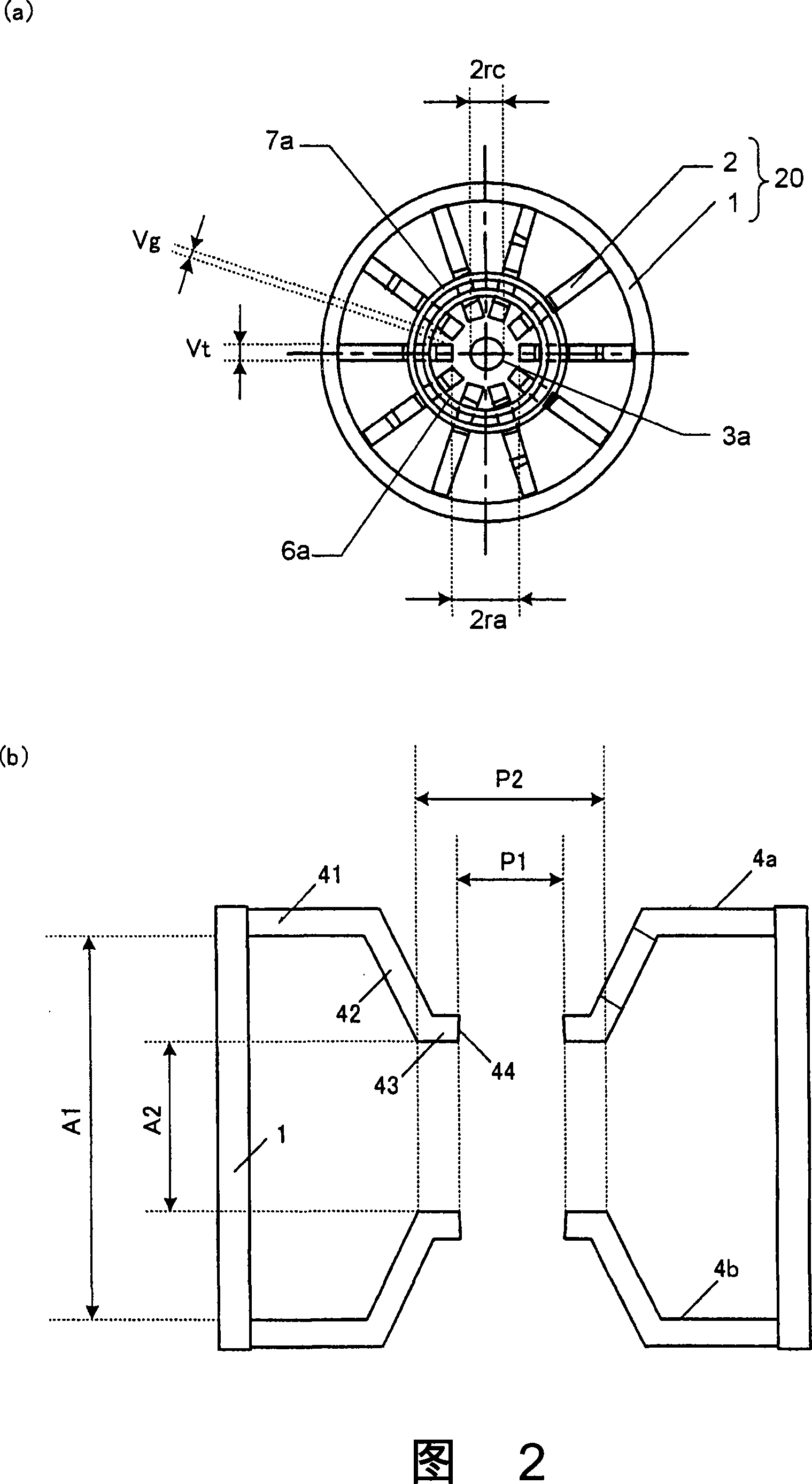

[0046] FIG. 1 is a sectional view of main parts of a main body of a magnetron 100 according to this embodiment. In addition, FIG. 2( a ) is a schematic top view showing main parts of the anode portion 20 and cathode portion 3 of the extracted magnetron 100 , and FIG. 2( b ) is an enlarged view of the pole pieces 4 a and 4 b.

[0047] As shown in Figure 1 and Figure 2 (a), the oscillating body part of the magnetron 100 has: an anode cylinder 1 and a plurality of blades 2 arranged radially from the inner wall of the anode cylinder 1 to the tube axis k at equal intervals An anode part 20 constituted; and a cathode part 3 having a helical filament 3a disposed inside the anode cylinder 1 along the tube axis k. A pair of end caps 3b, 3c are provided at both ends of the filament 3a.

[0048] The outer end of the blade 2 is fixed on the inner wall of the anode cylinder 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com