Conveyor having a conveyor belt with flights, including segmented flights for gapless end transfer

A conveying device, conveyor belt technology, used in transportation and packaging, packaging, conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

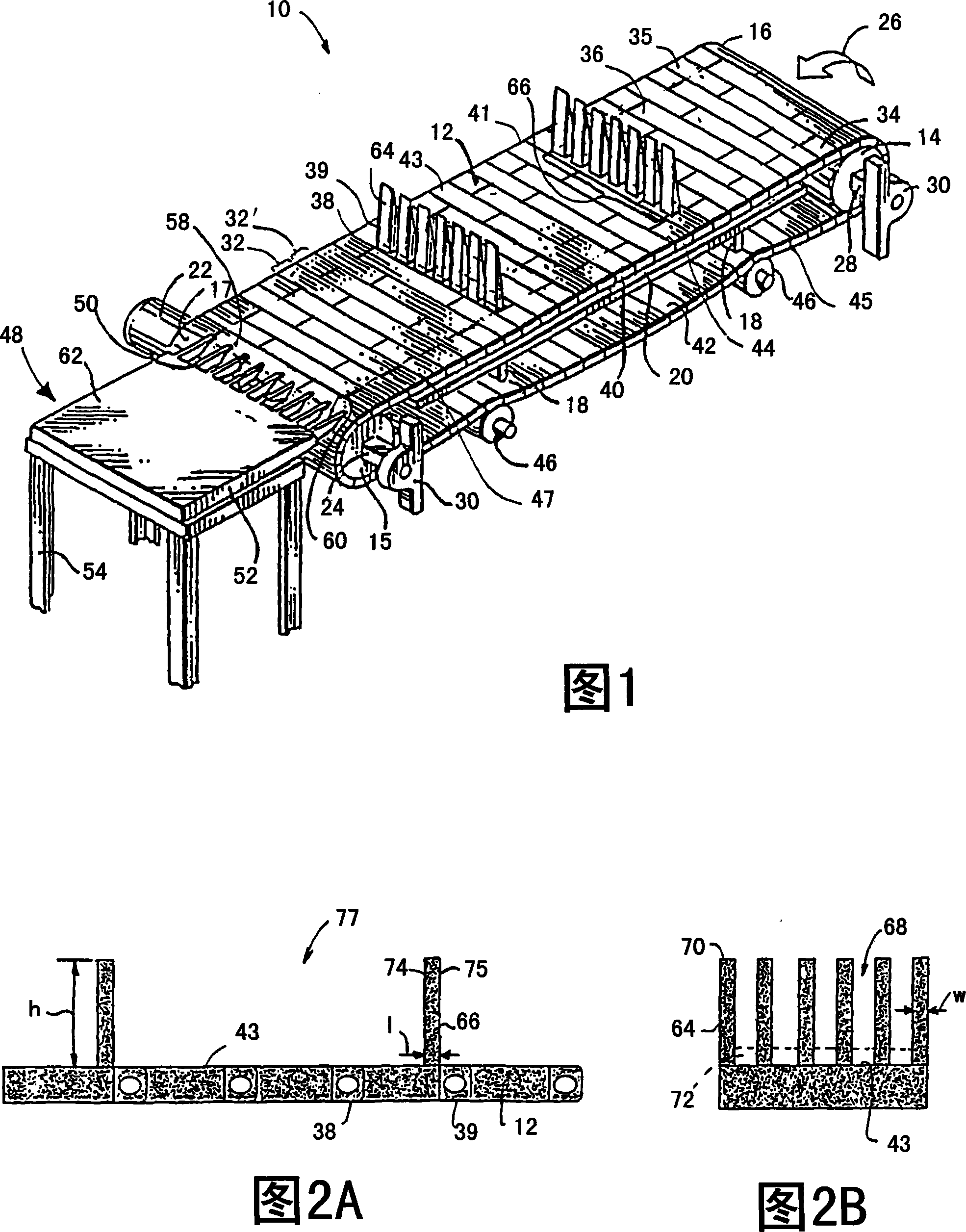

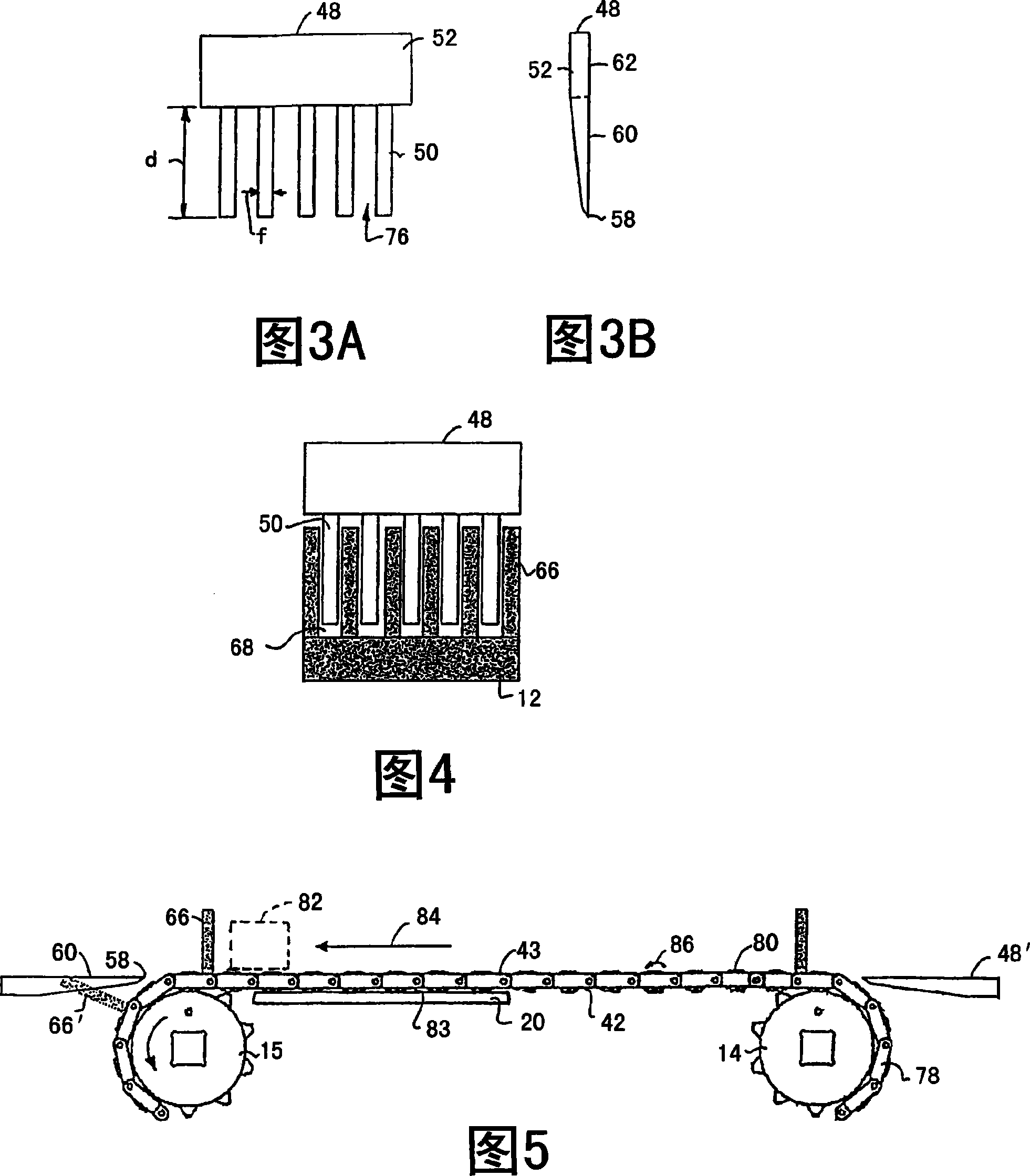

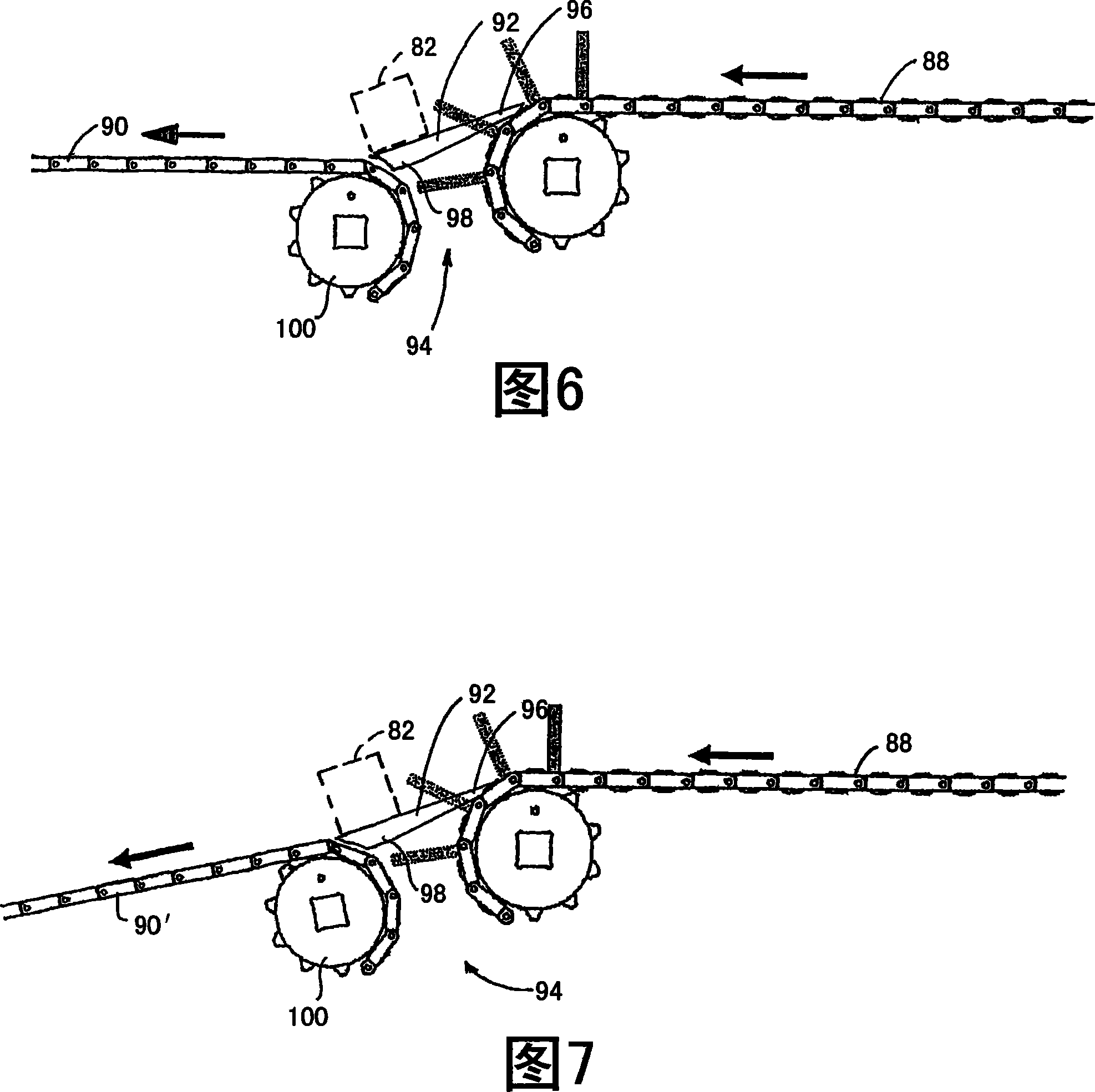

[0021] A delivery device embodying features of the present invention is shown in FIG. 1 . The conveyor 10 comprises a conveyor belt 12 in the form of a belt loop wound around a pair of sprocket sets 14, 15 or rollers defining opposite ends 16, 16, 17. The conveyor belt is supported in a frame 18 (shown only partially to avoid confusion) on top of a carryway pan 20 or wearstrip. Connected to a drive shaft 24 on which the drive sprocket set 15 is mounted, the motor 22 drives the belt in a direction 26 of belt travel. (With reversing of the motor or transmission, the belt can be driven in both directions). Motorized pulleys can be used in place of motorized drive shafts and drive sprockets, for example where space saving is critical. The other sprocket set 14 is mounted on an idle shaft 28 . Both the driven shaft and the drive shaft are supported at opposite ends in bearing housings 30 mounted on the conveyor frame.

[0022] Belt 12 is preferably a modular plastic belt such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com