Pyramid-shaped dumpling made of glutinous rice wrapped in bamboo leaves cooling and counting production flow line

A production line and zongzi technology, applied in baking, baked food, food science, etc., can solve the problems of low work efficiency, high labor intensity, high production cost, etc., achieve reasonable structure configuration, reduce production cost, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

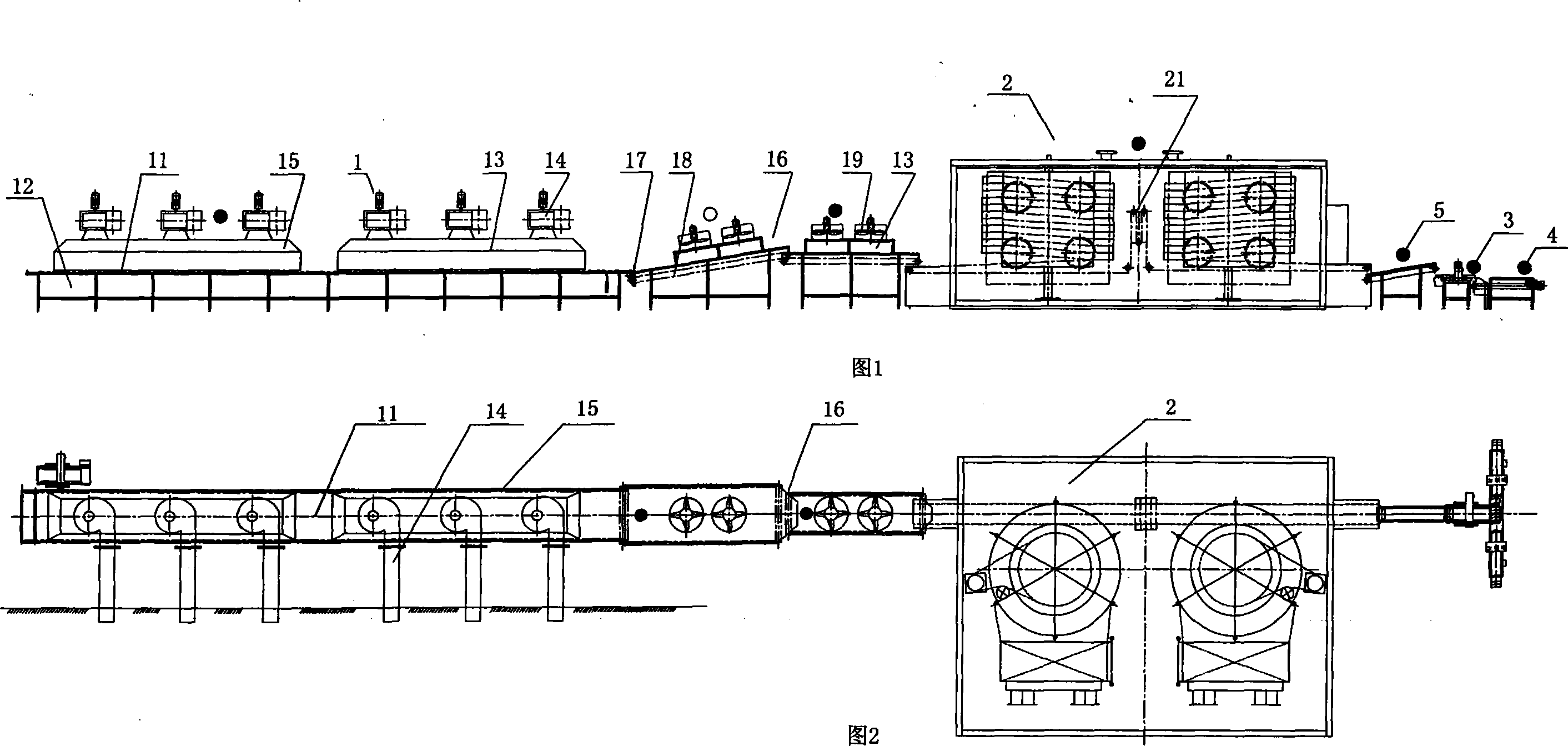

[0012] As shown in the drawings, the present invention is divided into six parts: the first part is air-cooled section one; the second part is air-cooled section two; the third part is air-cooled section three; the fourth part is spiral cooler 2; the fifth part is conveying Machine 5; The sixth part of metal detection 3 and removal; the seventh part of counting 4 and the electronic control system; the eighth part of the gas source part; automatic continuous operation can be implemented.

[0013] 1. The first part of the air-cooled section 1: the total length is 13.5m, and the width is 1.1m. It is conveyed by a whole basket of power rollers, with a conveying power of 2.2KW and an adjustable speed. The cooling section is 12.5m, divided into two sections. The front section is equipped with 3 5.5KW fans due to the large steam displacement, and the air volume is about 20,000m each 3 / h; 3 sets of 2.2KW centrifugal fans are installed in the back section, and the air volume is about 8500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com