Production device for tooth protection agent with fullerene

A technology for producing a device and a protective agent, applied in the field of tooth protection, can solve problems such as difficulty in dispersion, and achieve the effects of fast and efficient mixing, stable performance and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

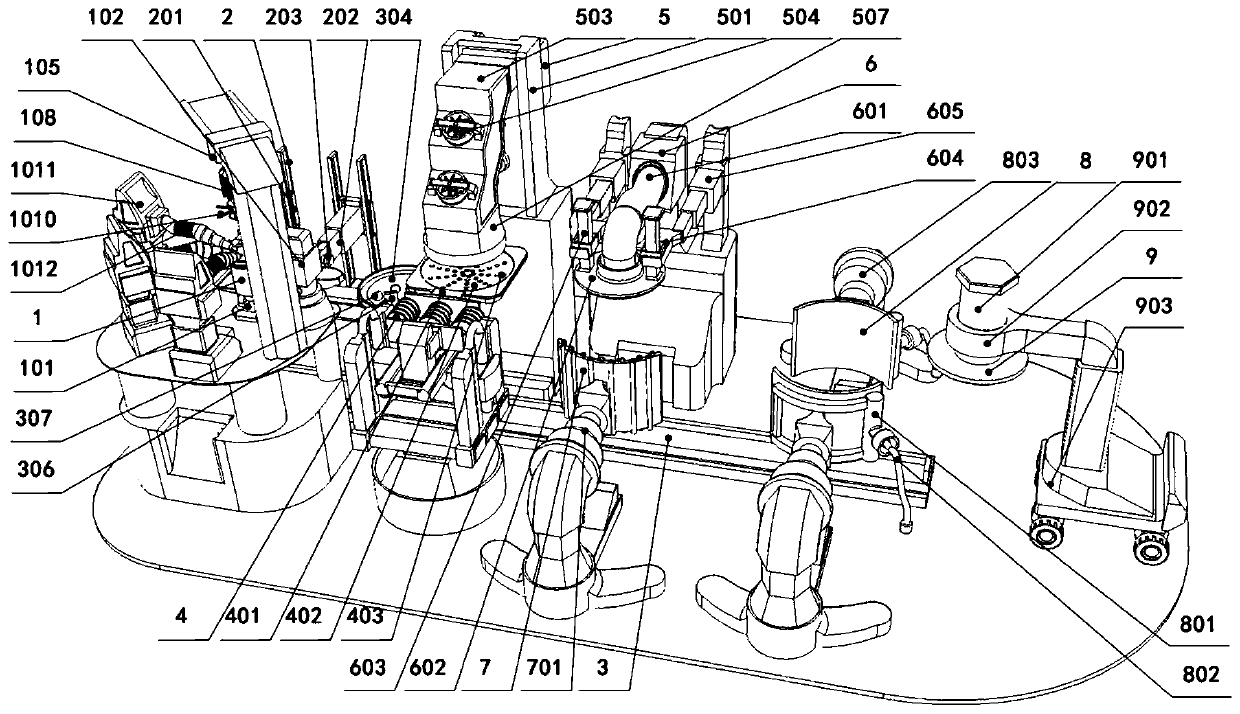

[0044] A kind of fullerene-containing tooth protectant production device described in the present embodiment is as Figure 1-14 As shown, including the mixing system, preparation system, feeding system, vacuum system, heating system, cooling system and sealing system set up in sequence;

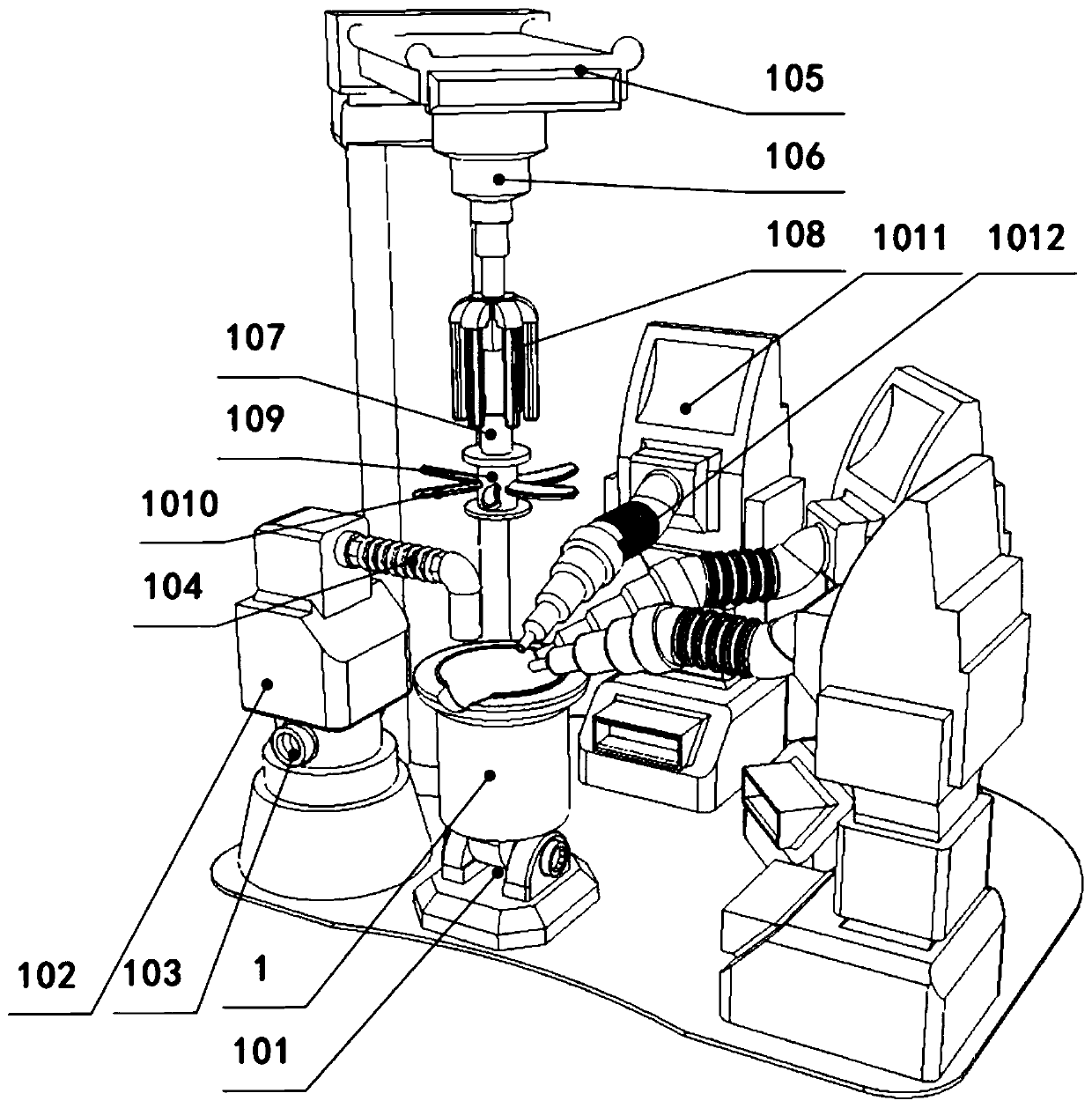

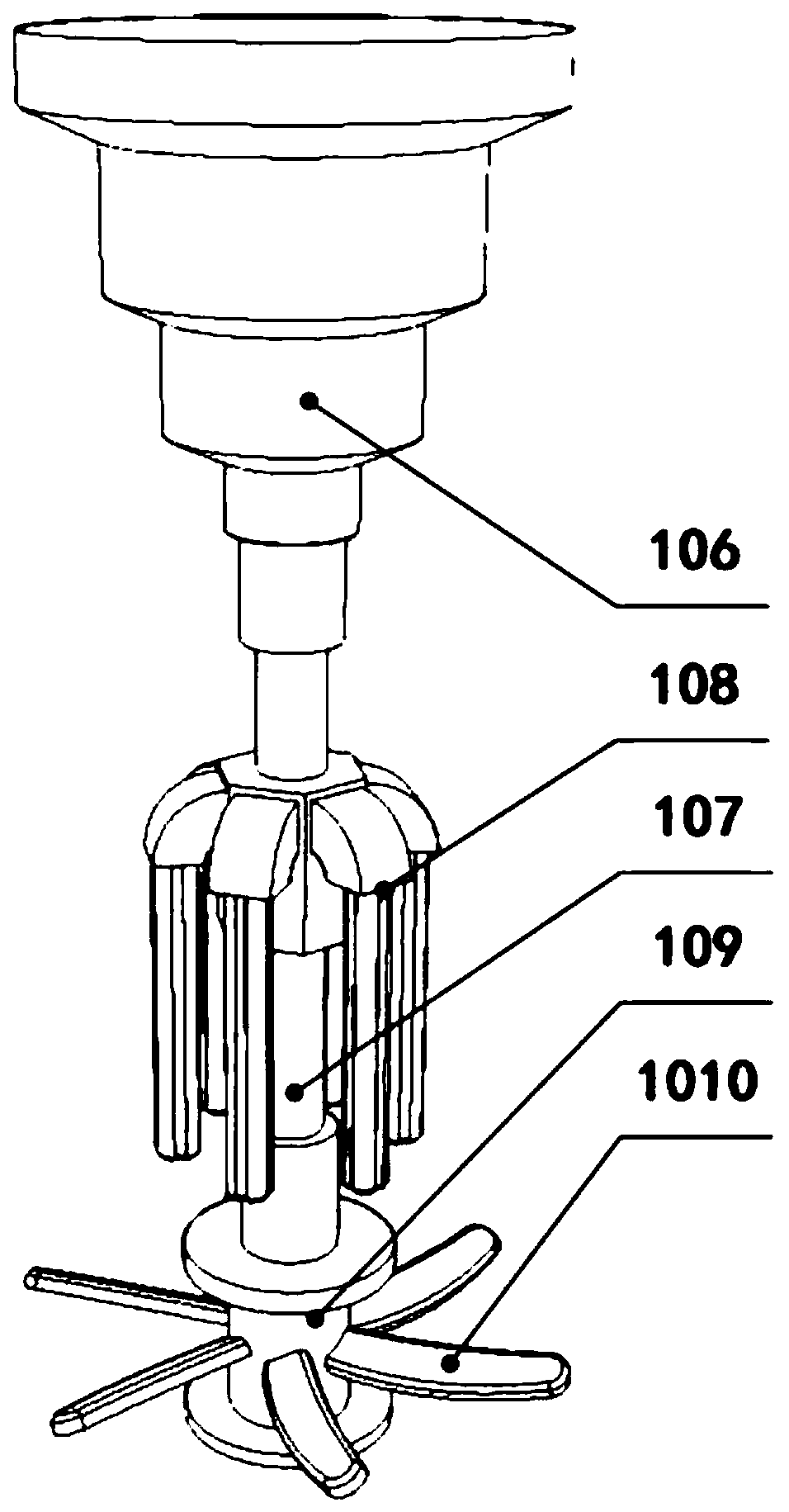

[0045]The mixing system includes a pre-dissolving pot 1, a joint base 101, and a transfer mechanism; the pre-dissolving pot 1 is arranged on the top of the joint base 101, and a water tank 102, a support 105 and several feeding machines are arranged around the pre-dissolving pot 1 1011, the lower end of the water tank 102 is provided with a water valve 103 for an external water source, the upper end of the water tank 102 is connected to a water pipe 104, the bracket 105 is connected to a telescopic rod 106, and the lower end of the telescopic rod 106 is connected to a connection in turn. Shaft 107, rotary joint 109, several heating rod arrays 108 are arranged on the connecting shaft 107, seve...

Embodiment 2

[0057] The fullerene-containing tooth protection agent production device described in this embodiment is the same as that in Embodiment 1, except that a flow control valve 205 is provided at the lower end of the funnel 204 described in this embodiment. Figure 5 As shown, the control valve 205 can well control the amount and rate of pouring out the mixed liquid.

Embodiment 3

[0059] The fullerene-containing tooth protection agent production device described in the embodiment is the same as that in Example 1, except that a filter screen 508 is provided on the channel 503 wall where the fan 504 is located in this implementation, and the filter screen 508 can prevent fullerenes from flying The outlet channel 503 can also prevent impurities from being mixed into the channel 503, thus ensuring product quality well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com