Energy-saving type pouring forming equipment for building formworks

A technology for building formwork and forming equipment, applied in the field of pouring, can solve problems such as low efficiency and high resource consumption, and achieve the effects of improving stability, improving processing efficiency, and avoiding concrete splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

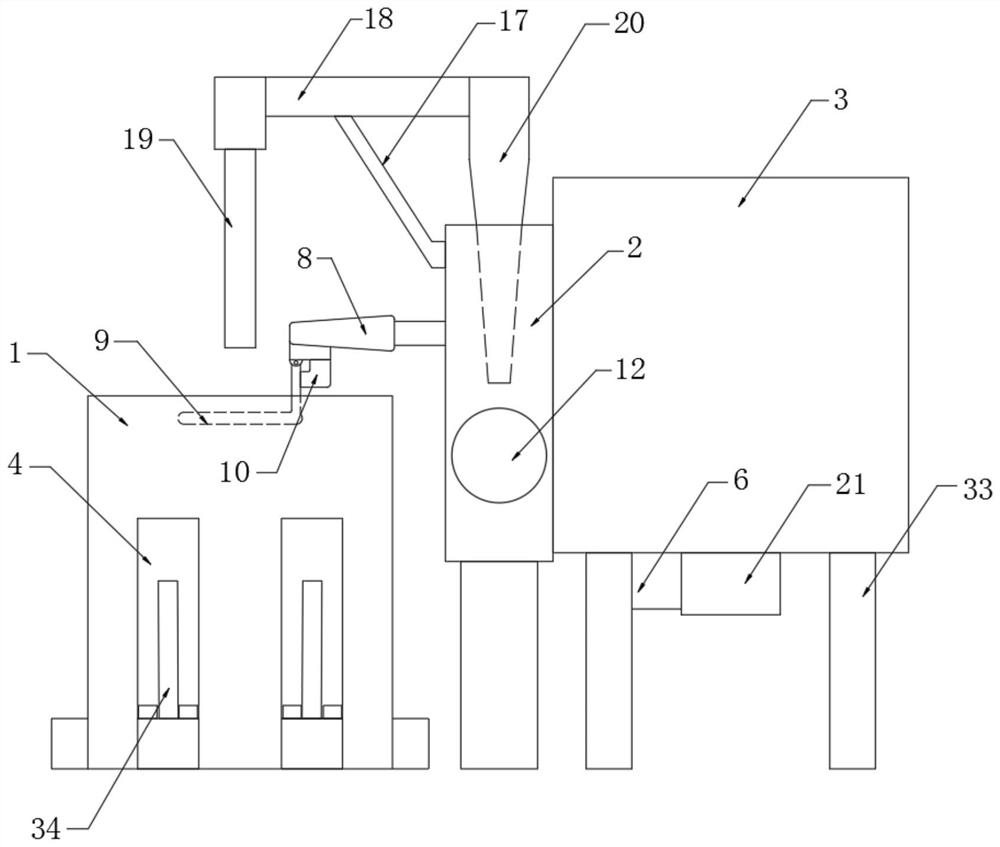

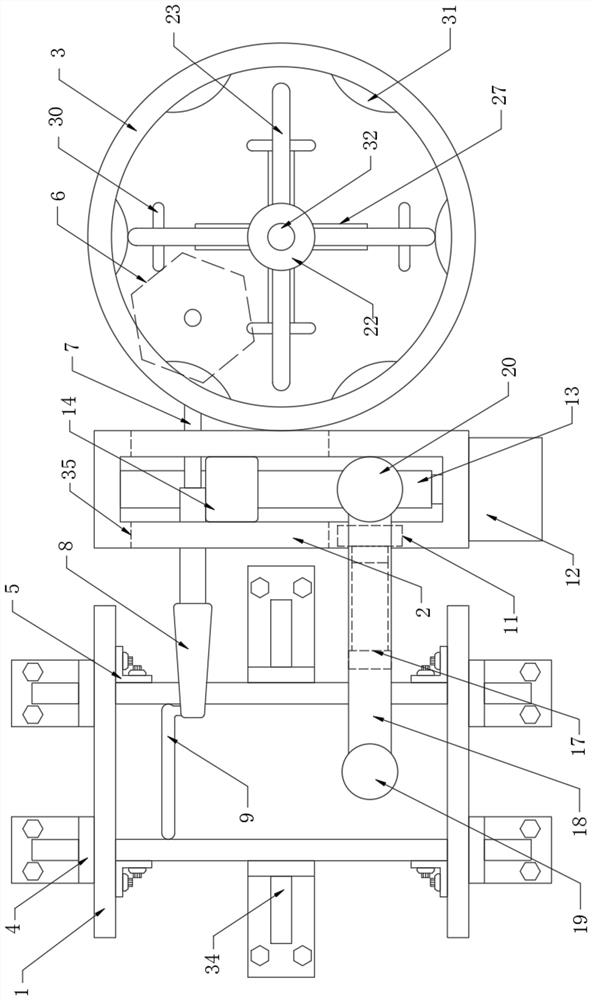

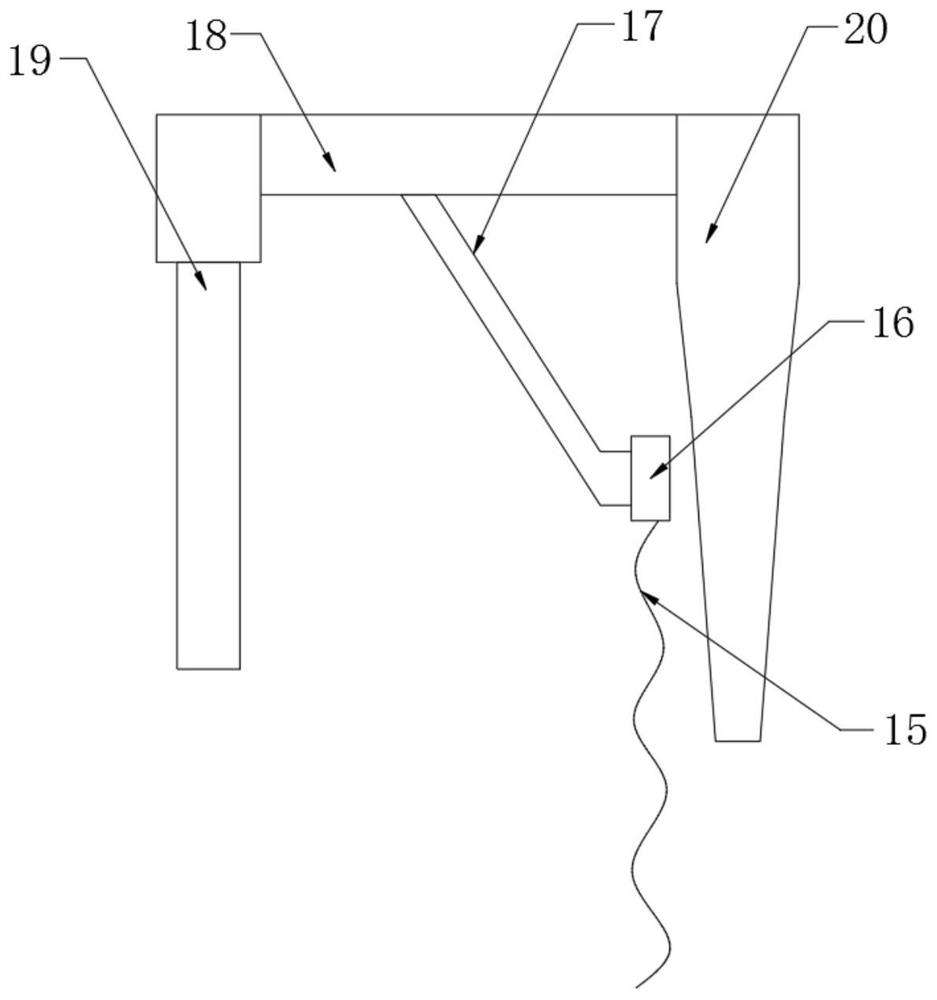

[0027] refer to Figure 1-5 , a pouring molding equipment for energy-saving building templates, including a plurality of templates 1, an intermediate frame 2 and a mixing box 3, the side walls of each template 1 are offset by support plates 4, and the side walls of each support plate 4 Both are fixed with support ribs 34, and the junction of every two adjacent templates 1 is jointly fixed with a connecting frame 5, and a plurality of legs 33 are fixed at the bottom of the mixing box 3, and a delivery pump 6 is fixed at the bottom of the mixing box 3, and the middle The side wall of the frame 2 is penetrated with a traversing groove 35, and the inner wall of the traversing groove 35 is slidably connected with a feeding head 8 and a conveying pipe 7, and one end of the conveying pipe 7 is connected with the feeding head 8 and the other end is connected with the conveying pump 6. 2 is provided with a driving mechanism, the side wall of the intermediate frame 2 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com