Automobile clutch pedal self-adaptive regulating structure

An adaptive adjustment, clutch pedal technology, applied in the field of automobile transmission, can solve problems such as difficult pedal surface layout angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

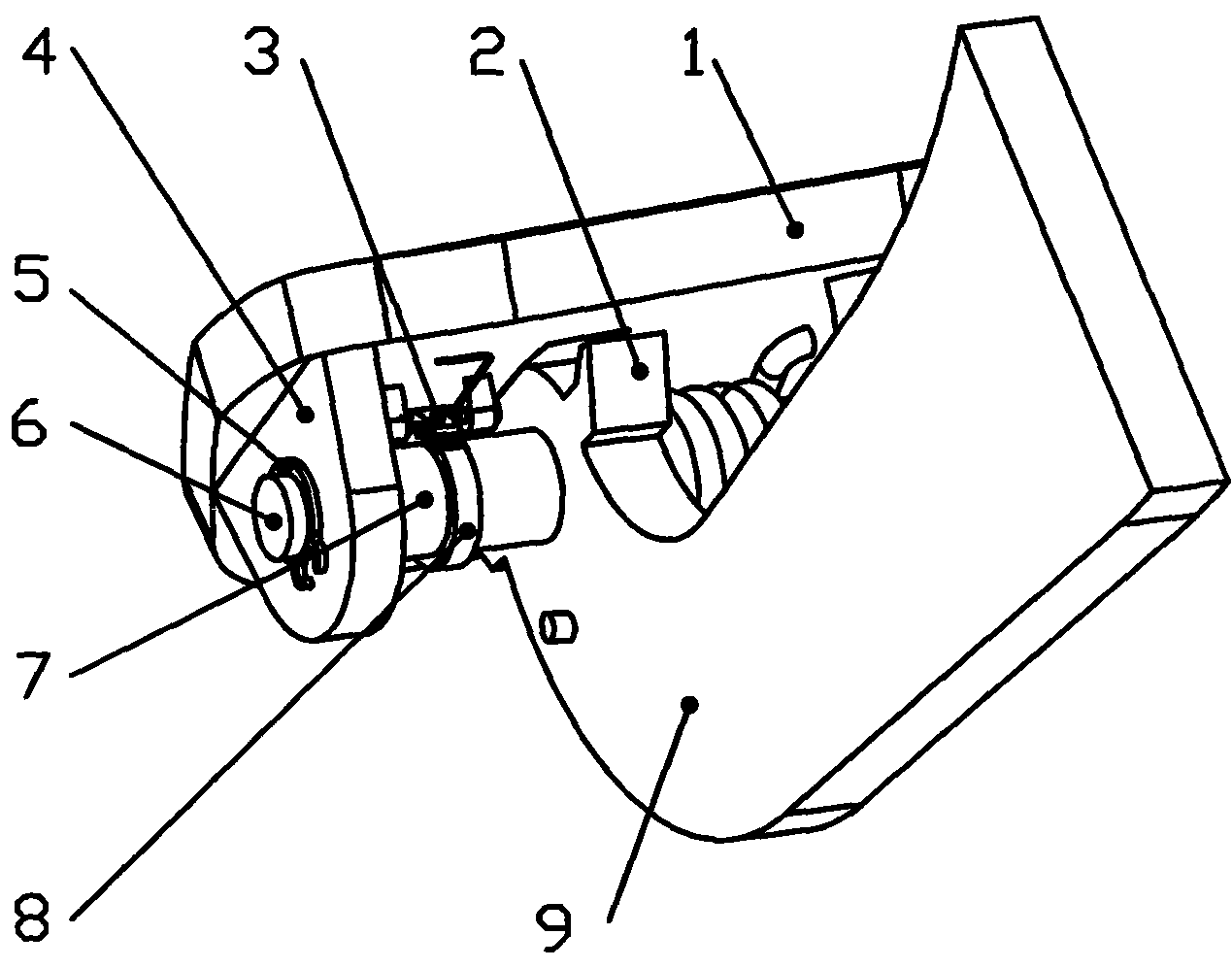

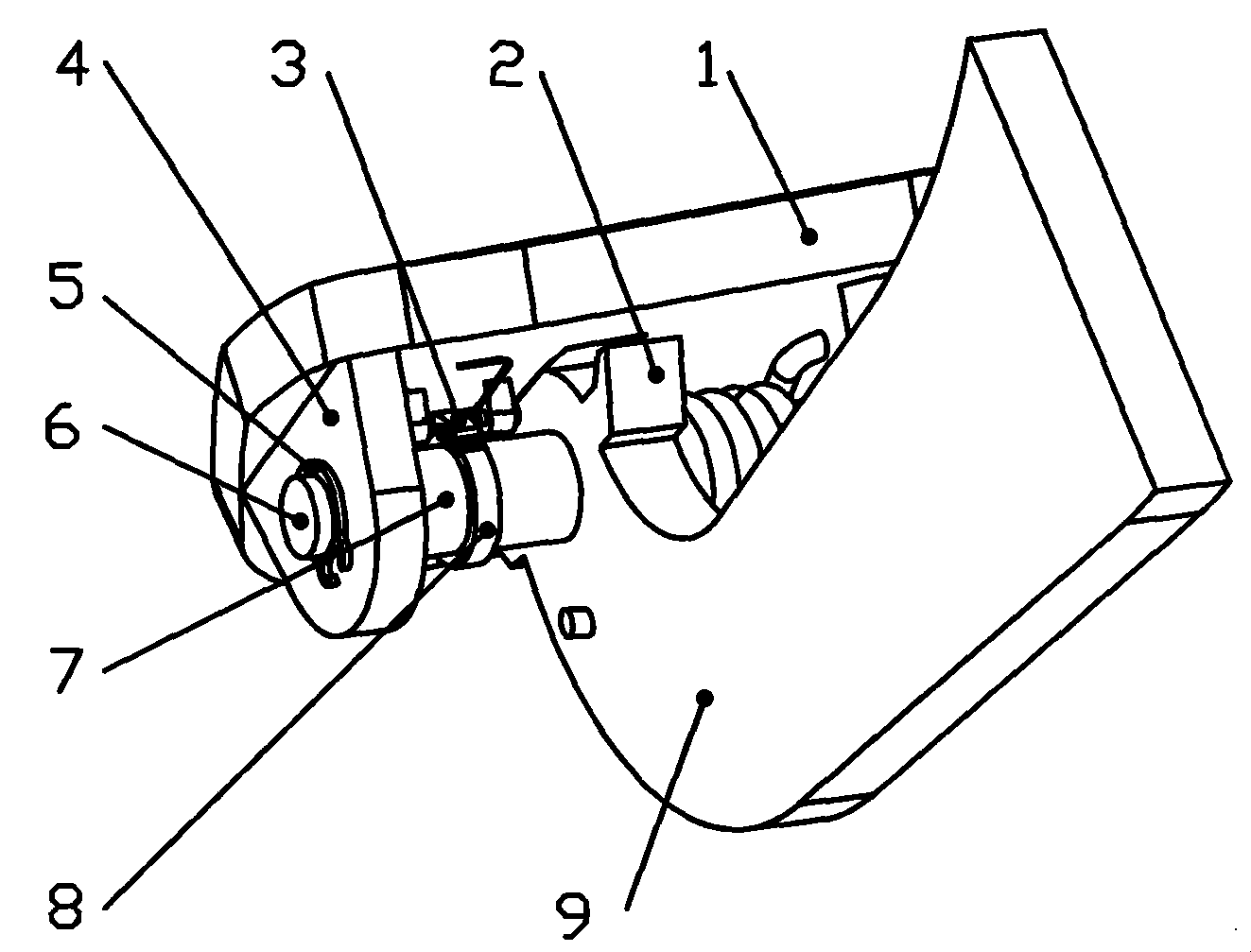

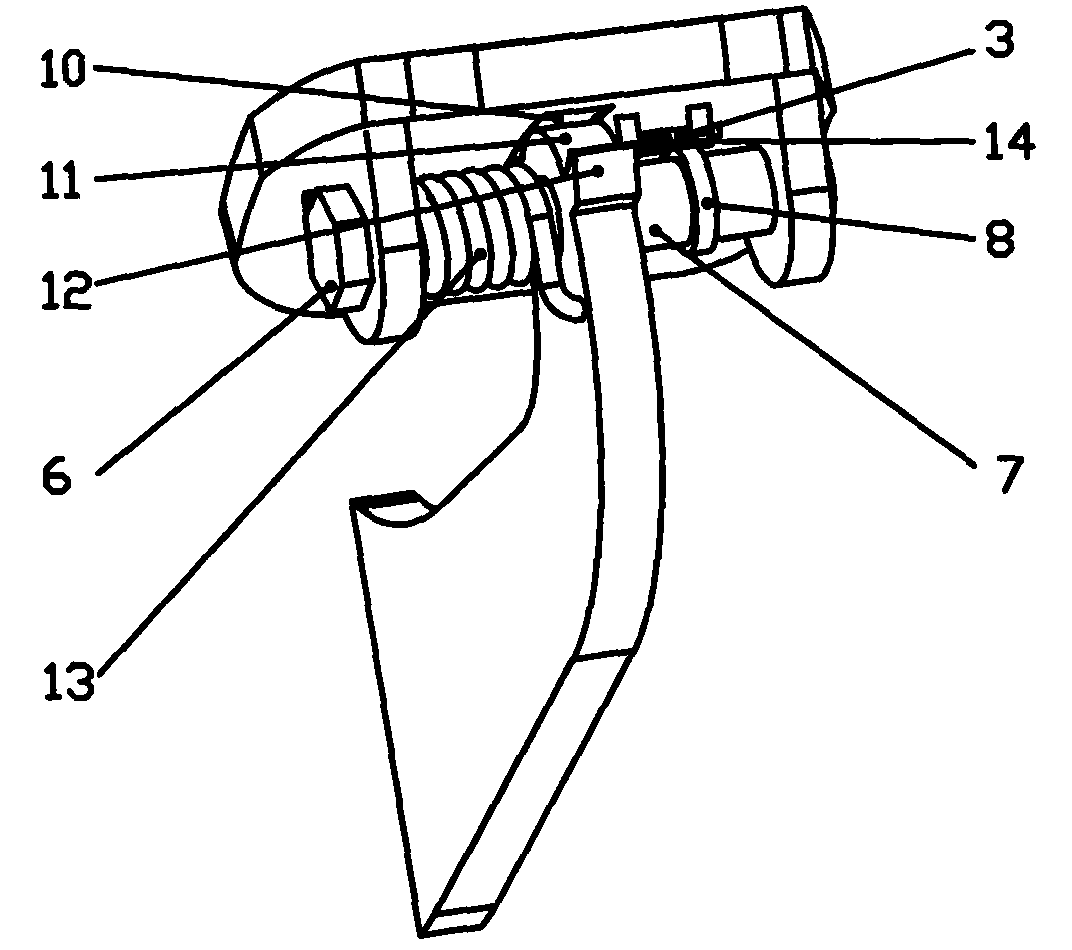

[0015] The adaptive adjustment structure of the automobile clutch pedal will be specifically described below in conjunction with the accompanying drawings.

[0016] As shown in Figures 1-3, the adaptive adjustment structure of the automobile clutch pedal includes a pedal surface 1, a pedal arm 9, a pedal shaft 6 and a return torsion spring, and the end of the pedal arm 9 has a semicircular boss 11 and Two step surfaces 2, 12, a guide groove 10 is formed at the position where the lower part of the pedal surface 1 is in contact with the pedal arm boss 11. When the pedal is depressed, the boss 11 at the end of the pedal arm 9 cooperates with the guide groove 10 , so that the pedal surface 1 can rotate relatively around the pedal rotating shaft 6 .

[0017] The step surface is divided into an upper limit step surface 2 and a lower limit step surface 12, which control the relative rotation angle of the pedal surface 1 to prevent the rotation angle from being too large and affecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com