Method for constructing steel truss over existing railway line and transporting, mounting and positioning bogie

A technology of installation and positioning, steel truss, applied in the direction of truss structure, truss girder, safety island, etc., can solve the problems of unguaranteed construction period, unsafe, national economic loss, etc., achieve simple assembly, ensure driving safety, and facilitate transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention are described in detail in conjunction with accompanying drawings:

[0052] 1. Construction method

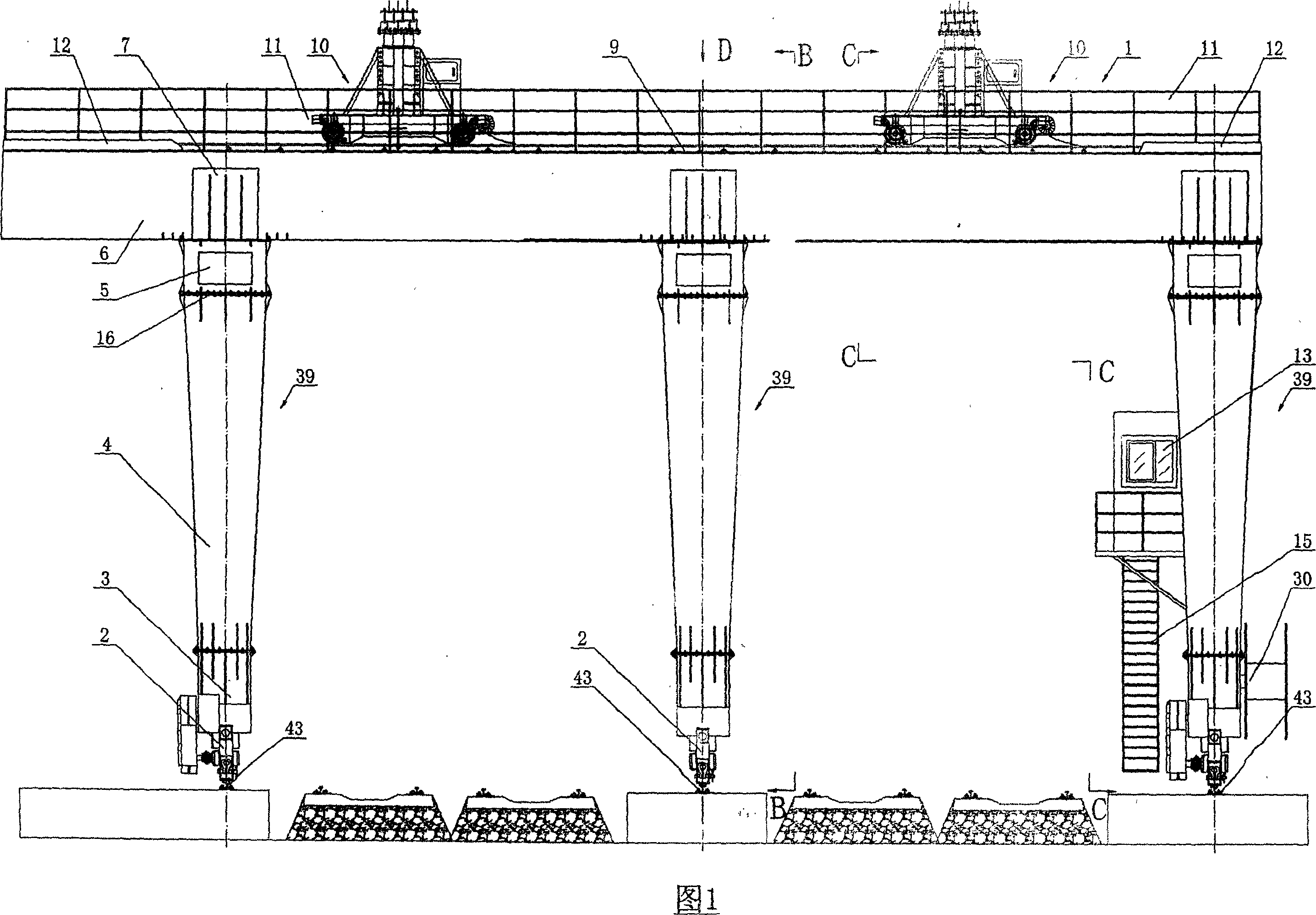

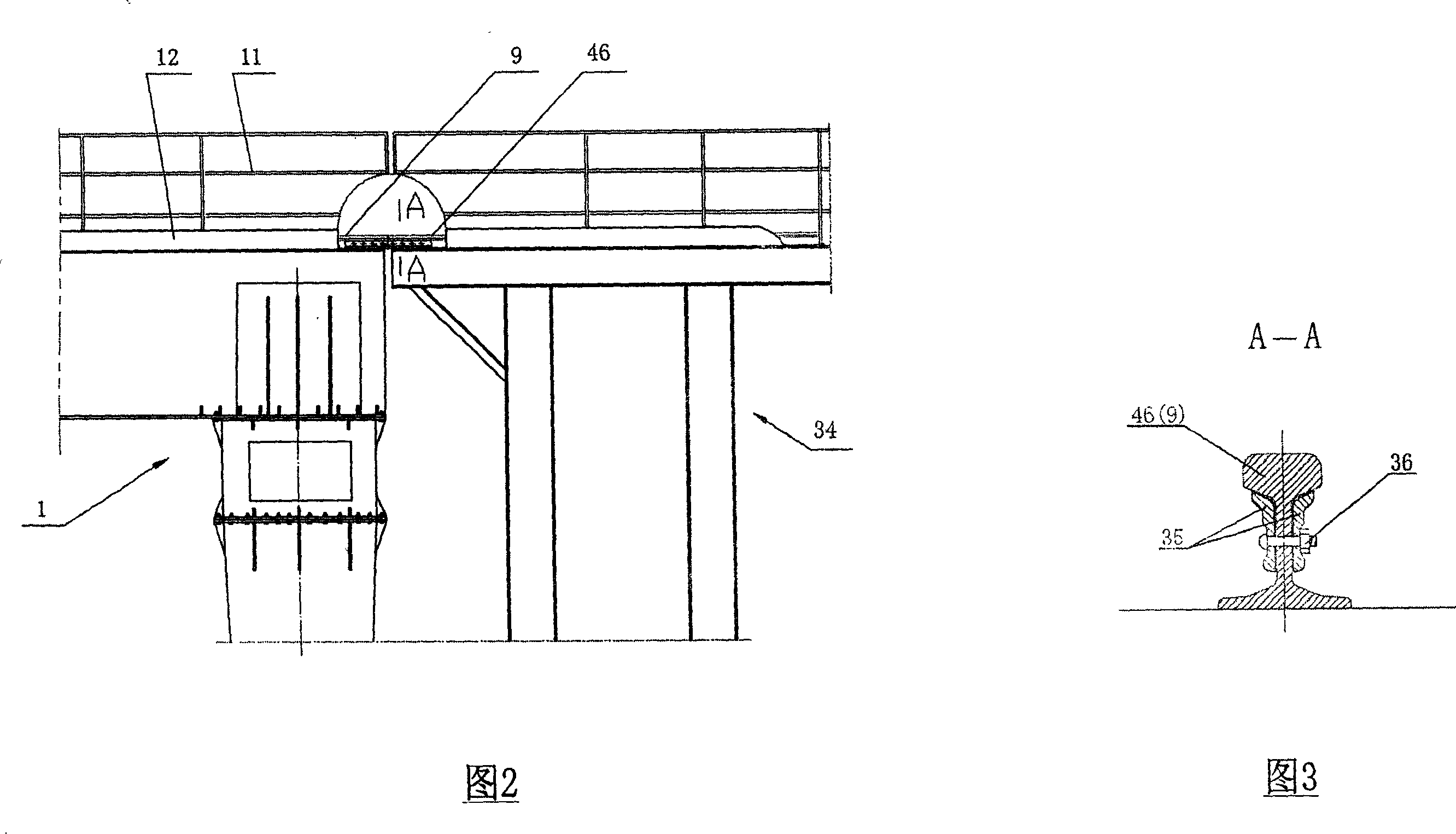

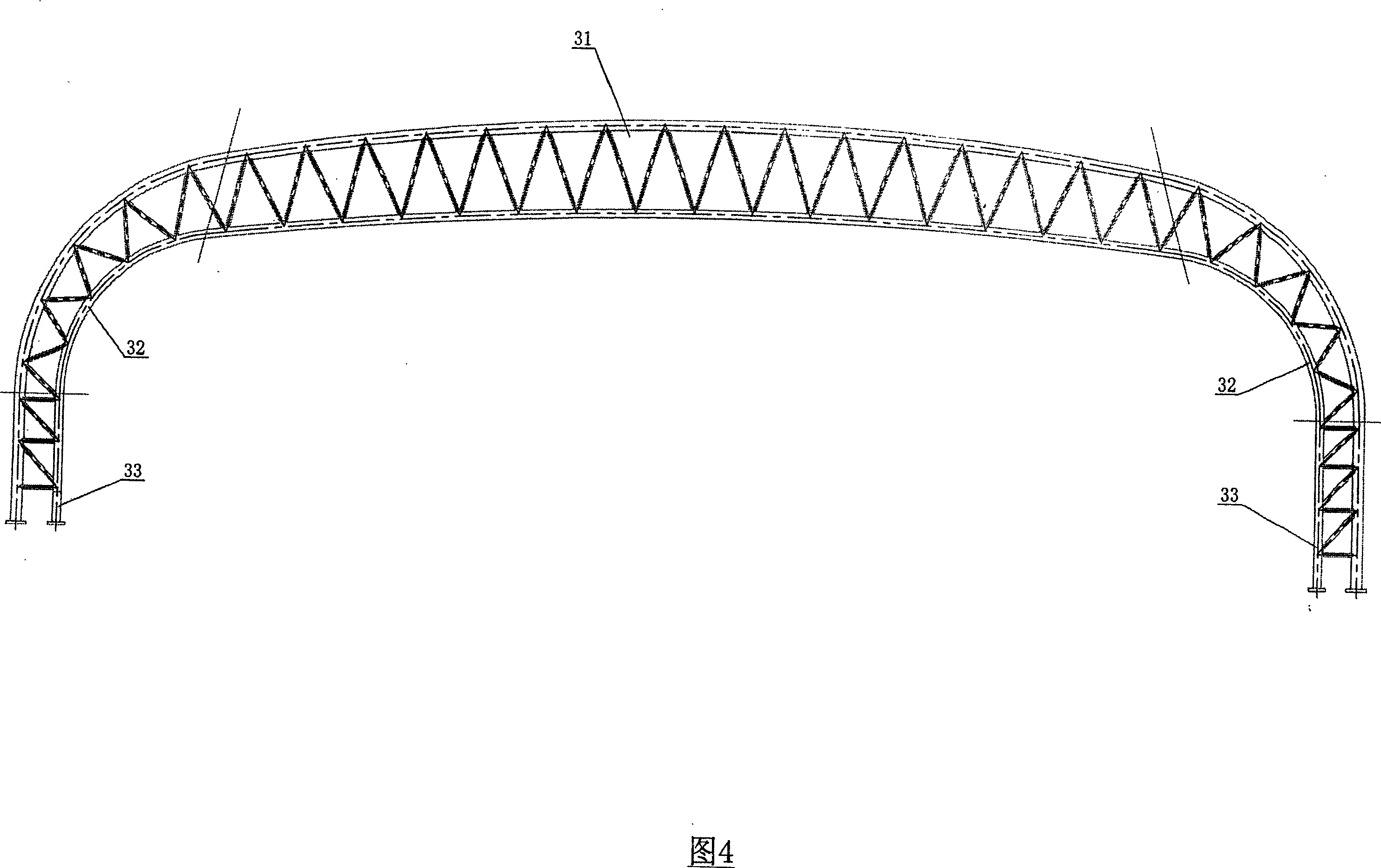

[0053] Figures 1, 2, 3, 8, 9, 10

[0054] Assemble five sections of the truss, one section of the main truss 31, two sections of truss elbows 32, and two sections of truss columns 33, and assemble them on the ground near the railway station according to the technical requirements, and then use the lifting equipment, the trestle 34 and the transportation, installation and positioning trolley 1 Transport each section of the truss to the installation position for construction across the railway station line.

[0055]The transportation of the main truss 31 is to transport, install and position trolley 1 row to the position parallel to the trestle 34, align the rails according to the technical requirements, and connect the rail 9 of the transport and installation 1 and the rail 46 of the trestle 34 with the fishplate 35 and the track bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com