Circuit breaker actuating mechanism and its lever anti-slip structure

A technology of operating mechanism and circuit breaker, which is applied in the direction of protection switch operation/release mechanism, contact operating parts, etc., which can solve the problems of inner or outer movement, operating mechanism falling apart, and large main spring tension, etc., so as to reduce the mechanical contact surface , reduce frictional resistance, improve the effect of mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

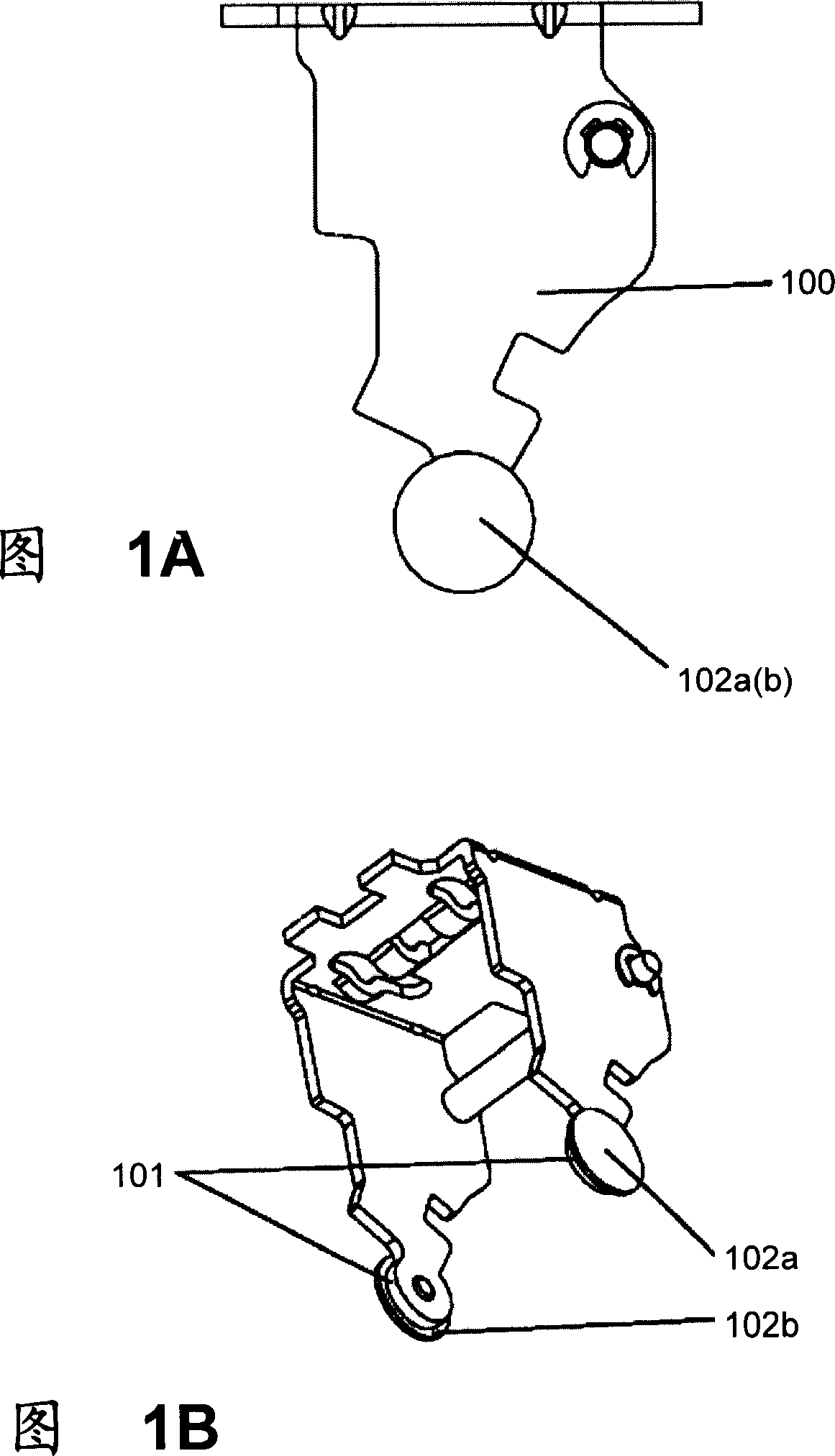

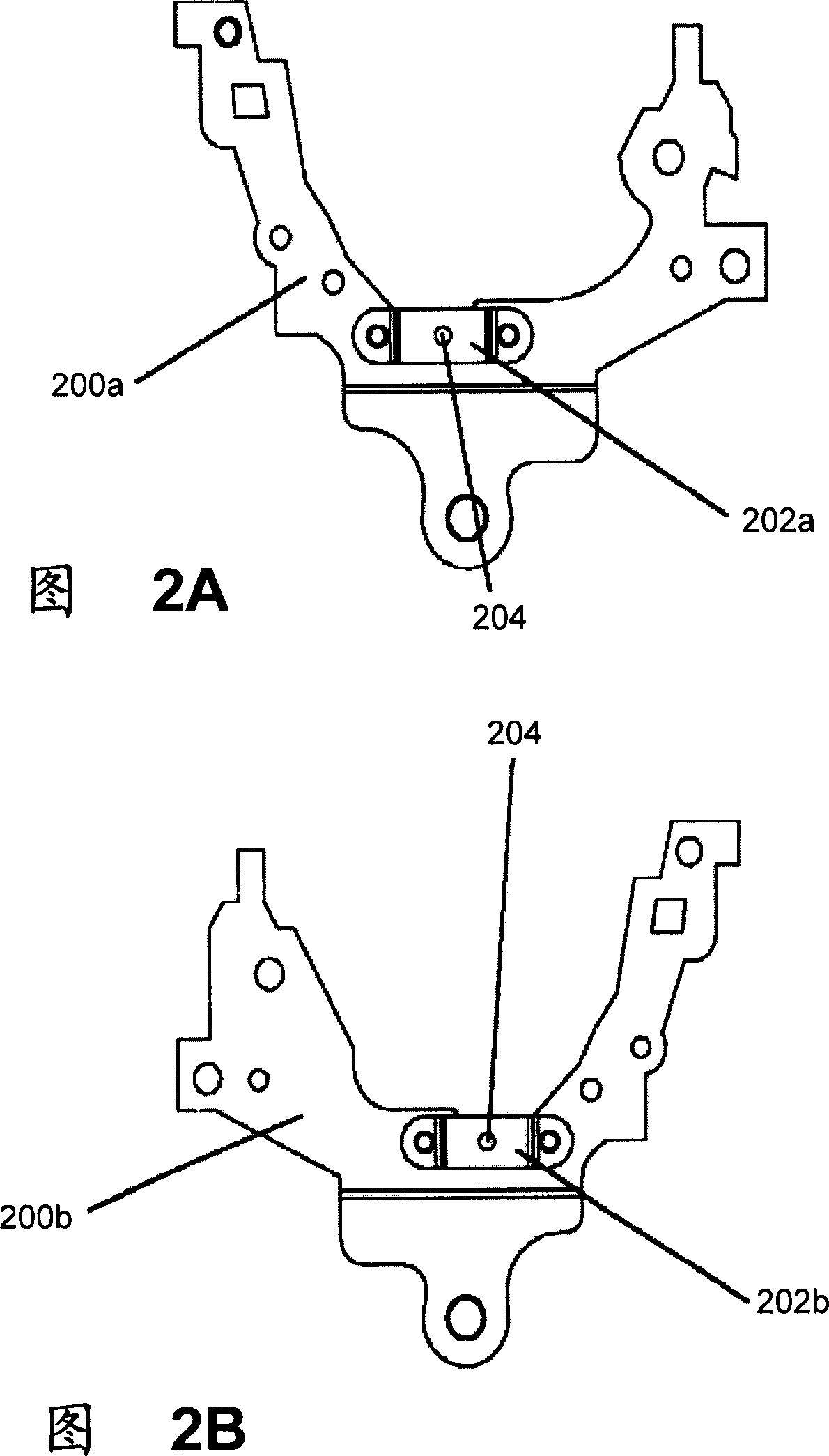

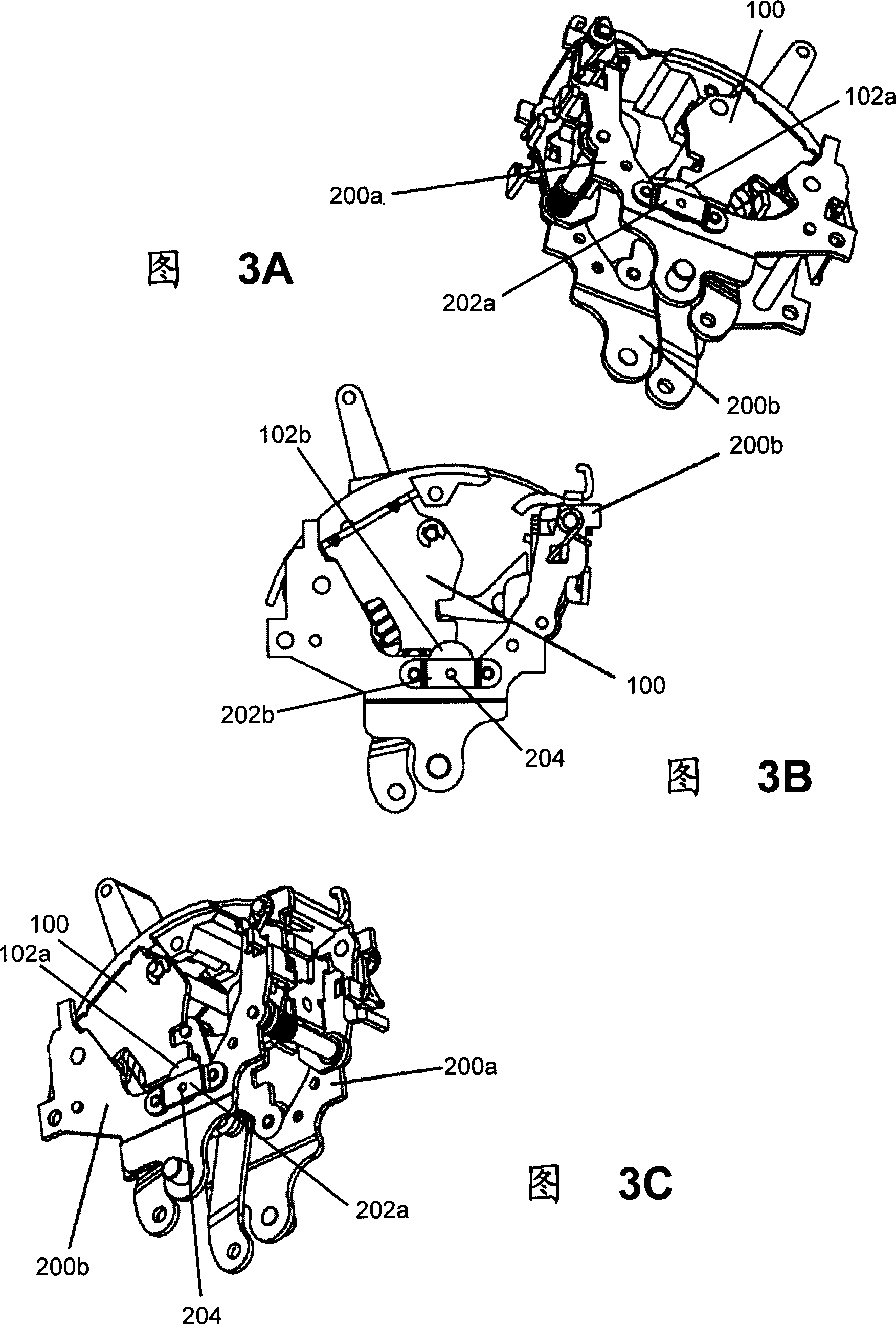

[0020] According to the present invention, there is provided an anti-slip structure for a lever in a circuit breaker operating mechanism, comprising: a side plate assembly fixed on the side plate of the circuit breaker operating mechanism, wherein the rotating foot of the lever is in rotatable contact with the side plate; The side plate assembly limits the pivoting foot of the lever from sliding outboard.

[0021] Preferably, the anti-skid structure further includes a lever assembly fixed on the rotating foot of the lever; the lever assembly cooperates with the side plate of the circuit breaker operating mechanism to limit the sliding of the rotating foot of the lever to the inside.

[0022] An example of a lever assembly can be realized using a baffle, such as a circular baffle, fixed to the outside of the pivoting foot of the lever, and the size of the baffle is larger than the arc groove on the side plate that contacts the pivoting foot of the lever. The plate contacts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com