Elevator device

A technology for elevators and elevator shafts, which is used in elevators, transportation and packaging, elevators and other directions in buildings to achieve the effect of improving ride comfort and safety and improving installation workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

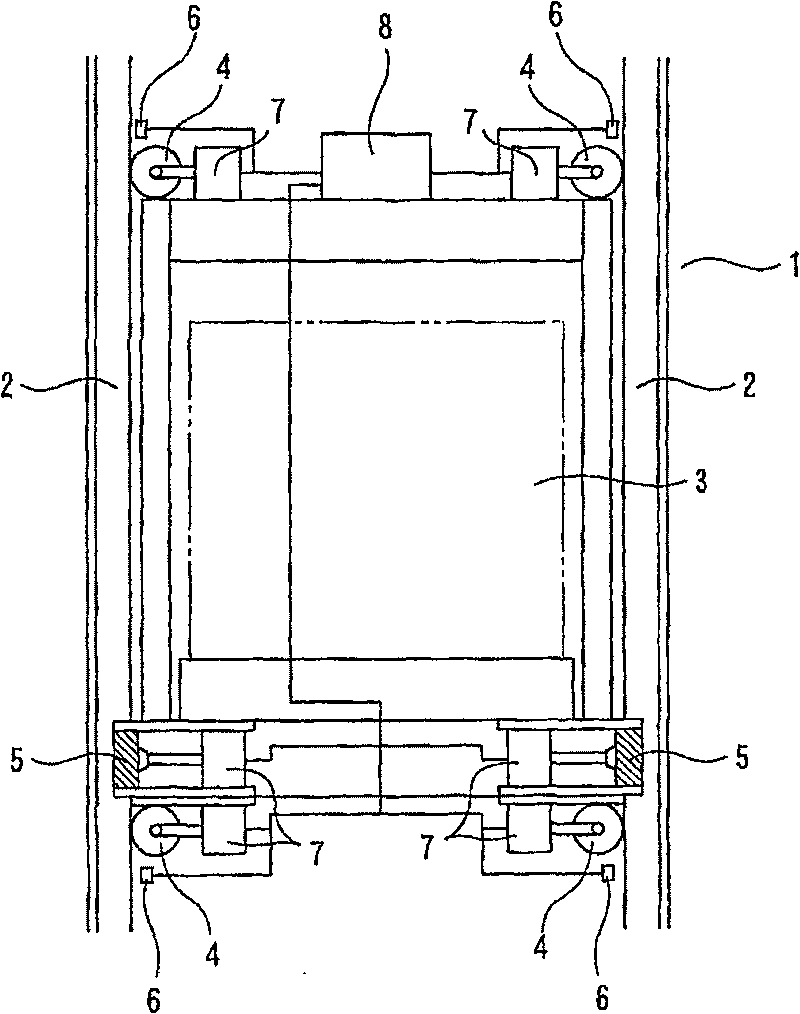

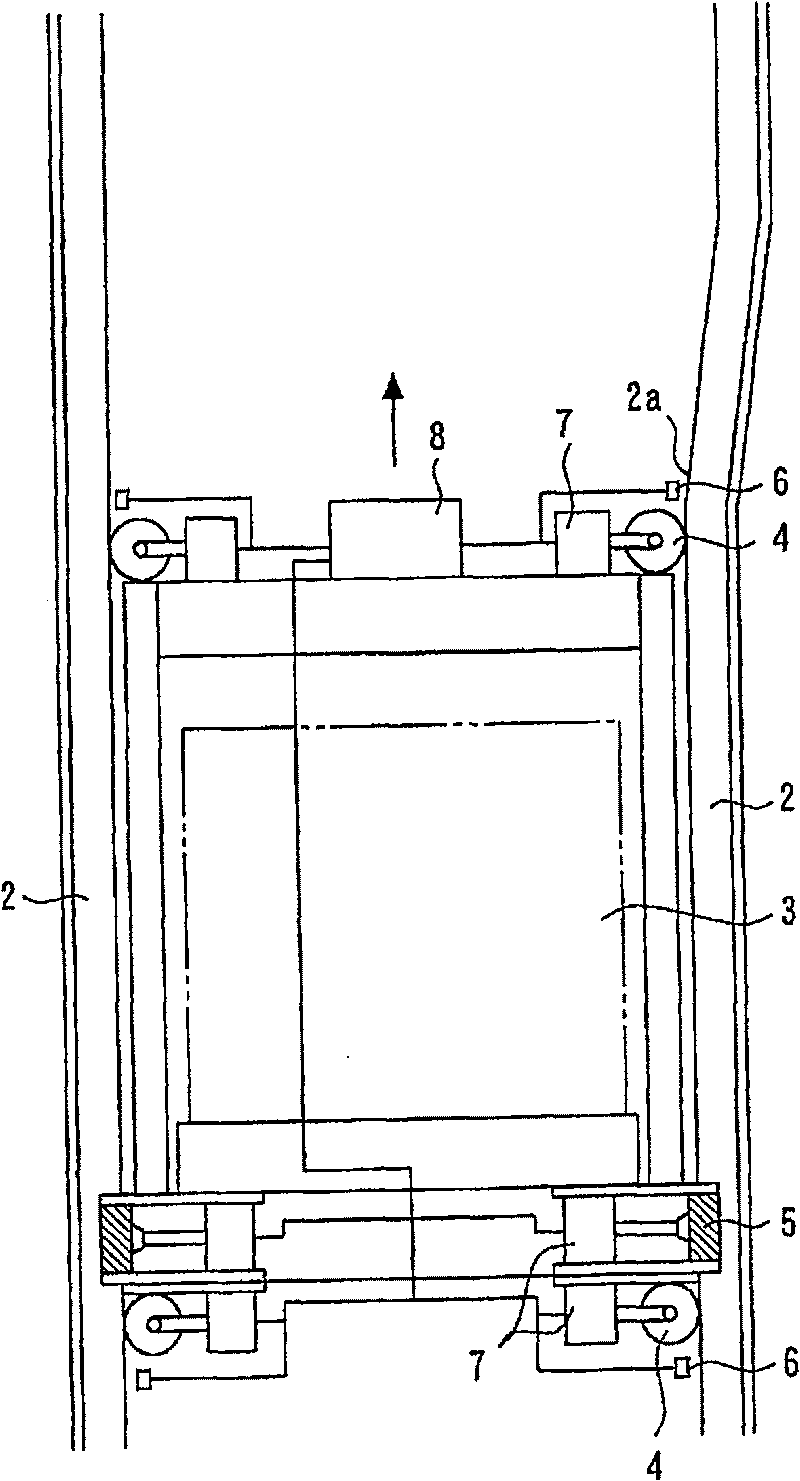

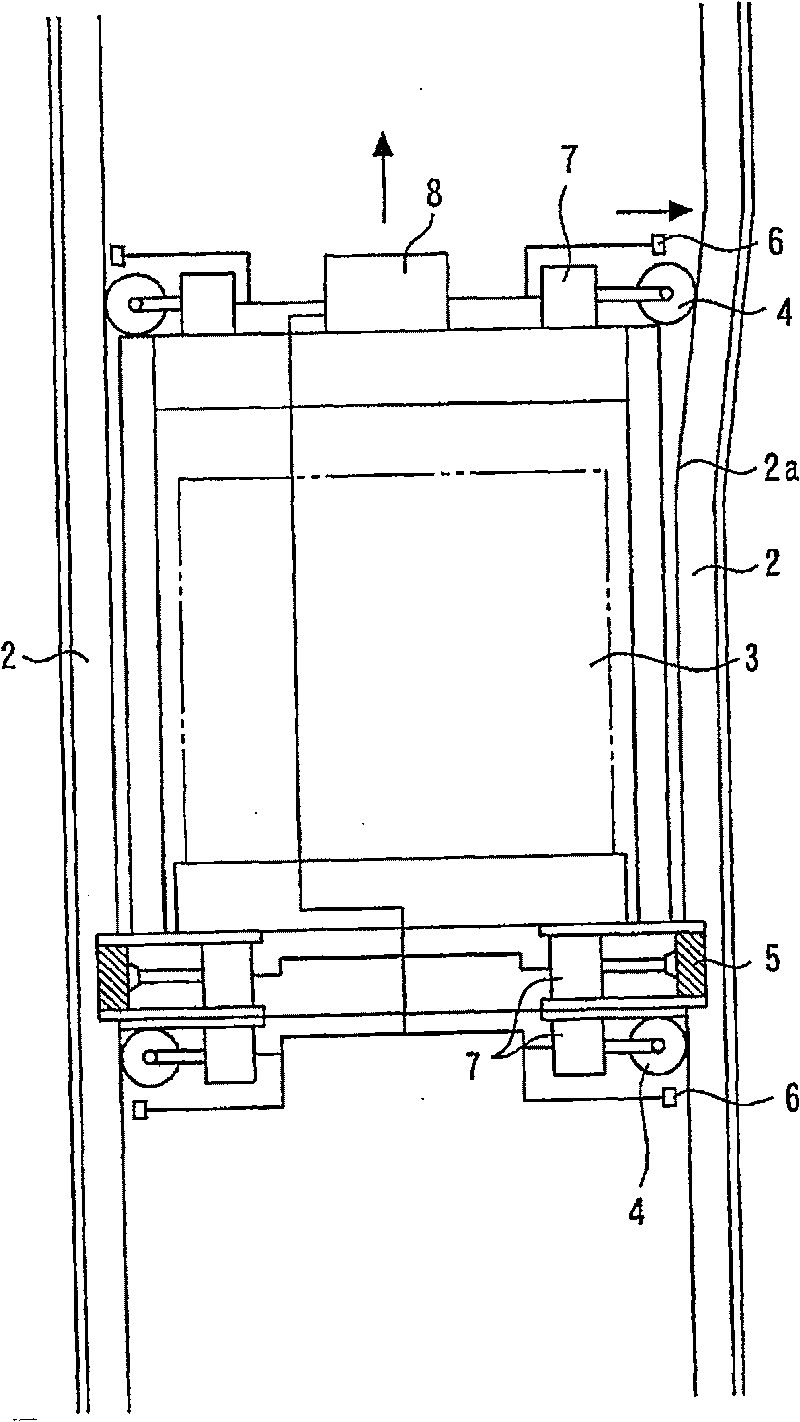

[0023] figure 1 It is a front view showing the elevator apparatus in Embodiment 1 of the present invention, figure 2 is the equivalent of an elevator device that represents a local change in the distance between guide rails figure 1 the picture, image 3 It is the equivalent of the state when the car is close to the position where the distance between the guide rails changes figure 2 the picture, Figure 4 It is a front view showing an elevator apparatus in which the distance between guide rails in Embodiment 1 of the present invention changes complicatedly, Figure 5 It is a front view showing the emergency stop device included in the elevator device according to Embodiment 1 of the present invention, Figure 6 It is equivalent to when the emergency stop device operates Figure 5 diagram.

[0024] In the figure, 1 represents the elevator shaft, and 2 represents a pair of left and right guide rails, which are respectively installed on the two side walls of the elevator...

Embodiment 2

[0041] In Example 1, the measuring device 6 is provided, but in Example 2, it is not necessary to provide it.

[0042] In the present embodiment 2, information such as the point where the distance between the left and right pair of guide rails 2 in the hoistway changes and the distance between the guide rails 2 is stored in the control device 8, and each driver 7 is operated based on this information. As a result, no measuring device is required, so that the construction and control of the elevator installation can be simplified.

Embodiment 3

[0044] Figure 7 It is a sectional view of a hoistway of an elevator apparatus according to Embodiment 3 of the present invention.

[0045] In the figure, 3a denotes a car of a self-propelled elevator. 1a denotes two elevator shafts of a self-propelled elevator, the distances between the guide rails of the elevator shafts are different, and the cars 3a move and rise and fall respectively in them. 1b represents a connecting passage connecting two elevator shafts 1a, and is a connecting means for moving the car 3a in the horizontal direction to and from between the two elevator shafts 1a. Here, the emergency stop device 5 adopts the structure described in the first embodiment.

[0046] According to the emergency stop device 5 provided in the elevator device constituted as described above, the same effect as that of Embodiment 1 can be obtained, and there is no need for a connection mechanism (upper tie rod, etc.) ), thus, there is no need to add a complicated structure for ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com