Positioning method and device for flexble printed circuit wiring plate relative cramping means

A technology of flexible printed circuit and wiring board, which is applied in the direction of electrical connection formation of printed components, electrical components, electrical components, etc., and can solve problems such as poor pass rate, short circuit, insufficient solder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

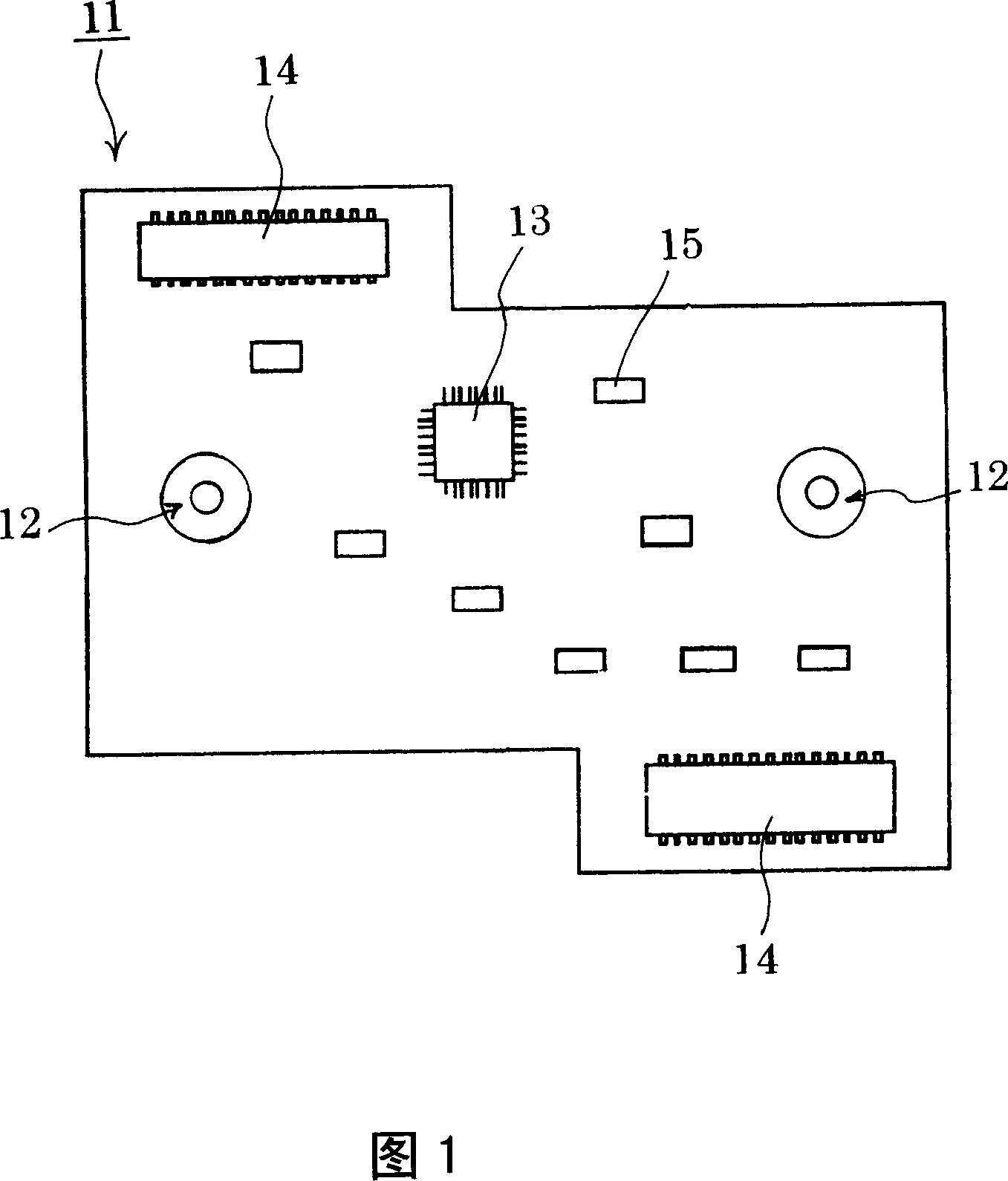

[0029] Fig. 1 is a conceptual diagram of a corresponding sheet-shaped flexible printed circuit wiring board (hereinafter referred to as FPC) 11 formed by stamping the outer shape. On the FPC 11 stamped into a corresponding sheet shape, reference positioning holes are provided at more than two positions. 12. In the illustrated example, a plurality of components including a semiconductor 13 and a connector 14 , a chip component 15 , etc. are mounted on a circuit pattern (not shown in the figure).

[0030] The above-mentioned reference positioning hole 12 constitutes a part of the second positioning mechanism 26 described later, but is provided through the base film, conductor and cover film constituting the FPC 11, and the hole diameters are different in the holes of the base film and the conductors and cover film.

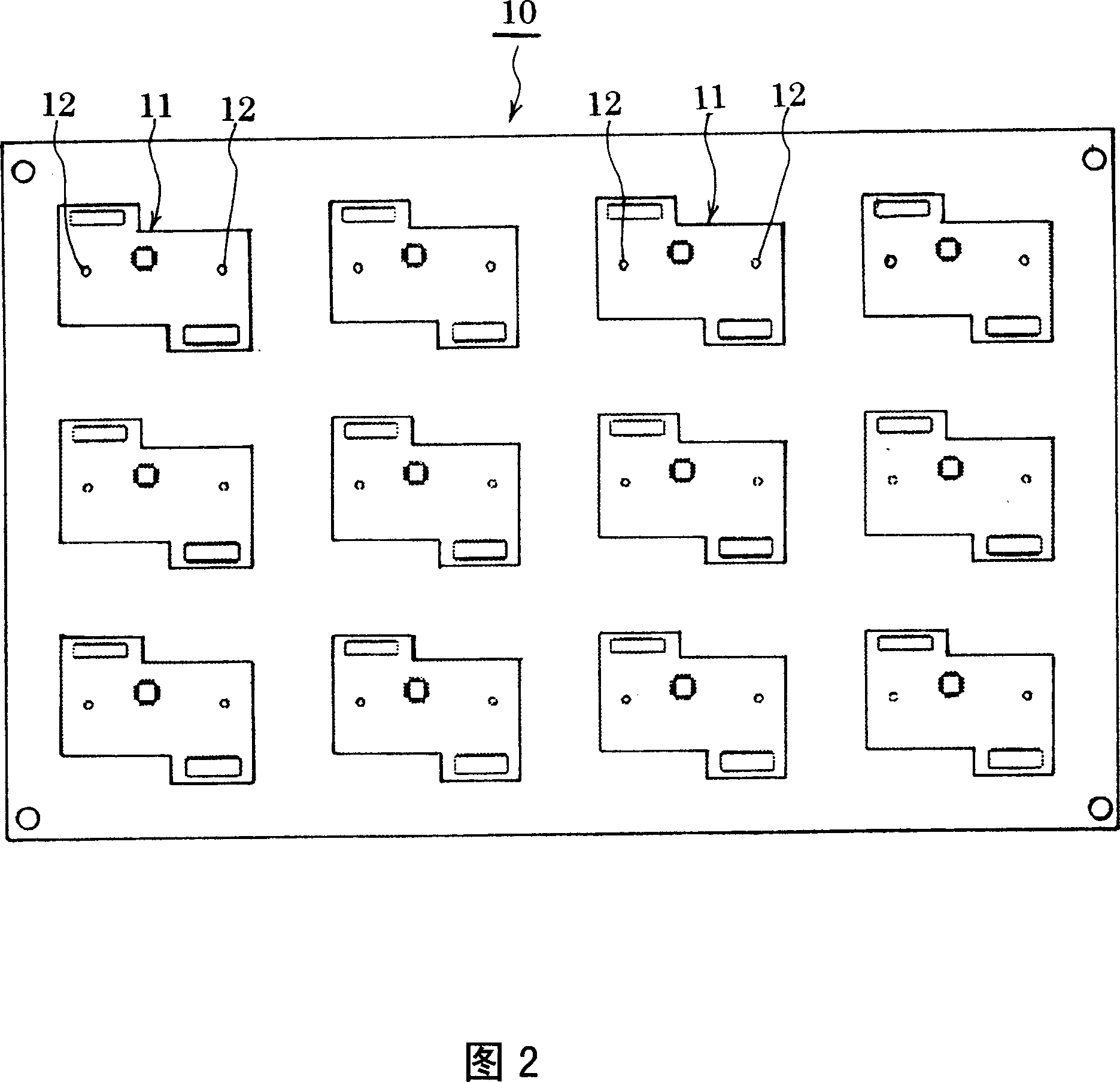

[0031] FIG. 2 shows an FPC sheet 10 on which a plurality of product FPCs 11 before press processing is placed. In this state, various holes (not shown) including t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com