Dust cover configuration body, grinding device and cutting device

A technology of dust cover and structure, which is applied in the direction of grinding/polishing safety device, grinding/polishing equipment, grinding machine, etc., and can solve problems such as complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

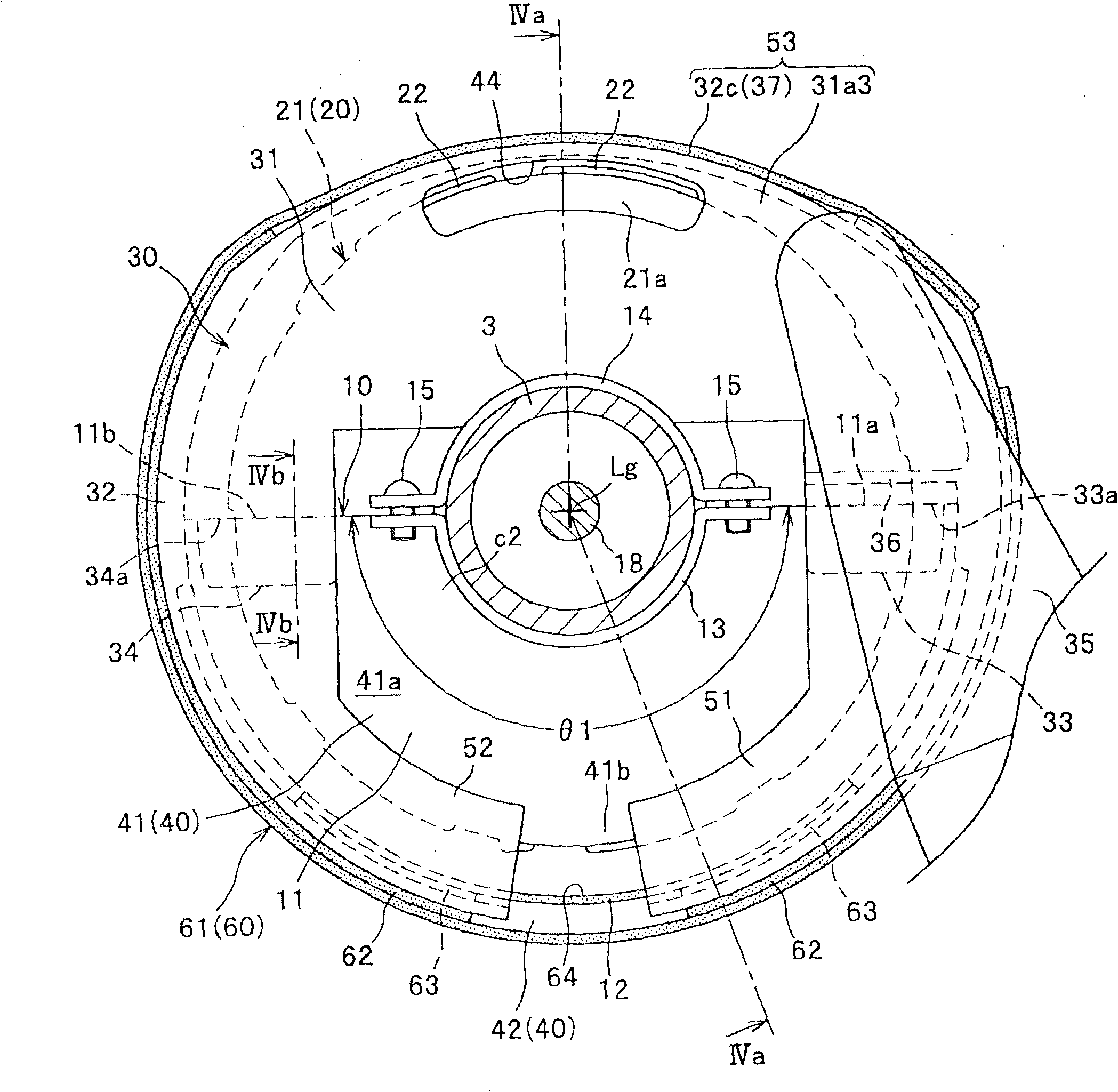

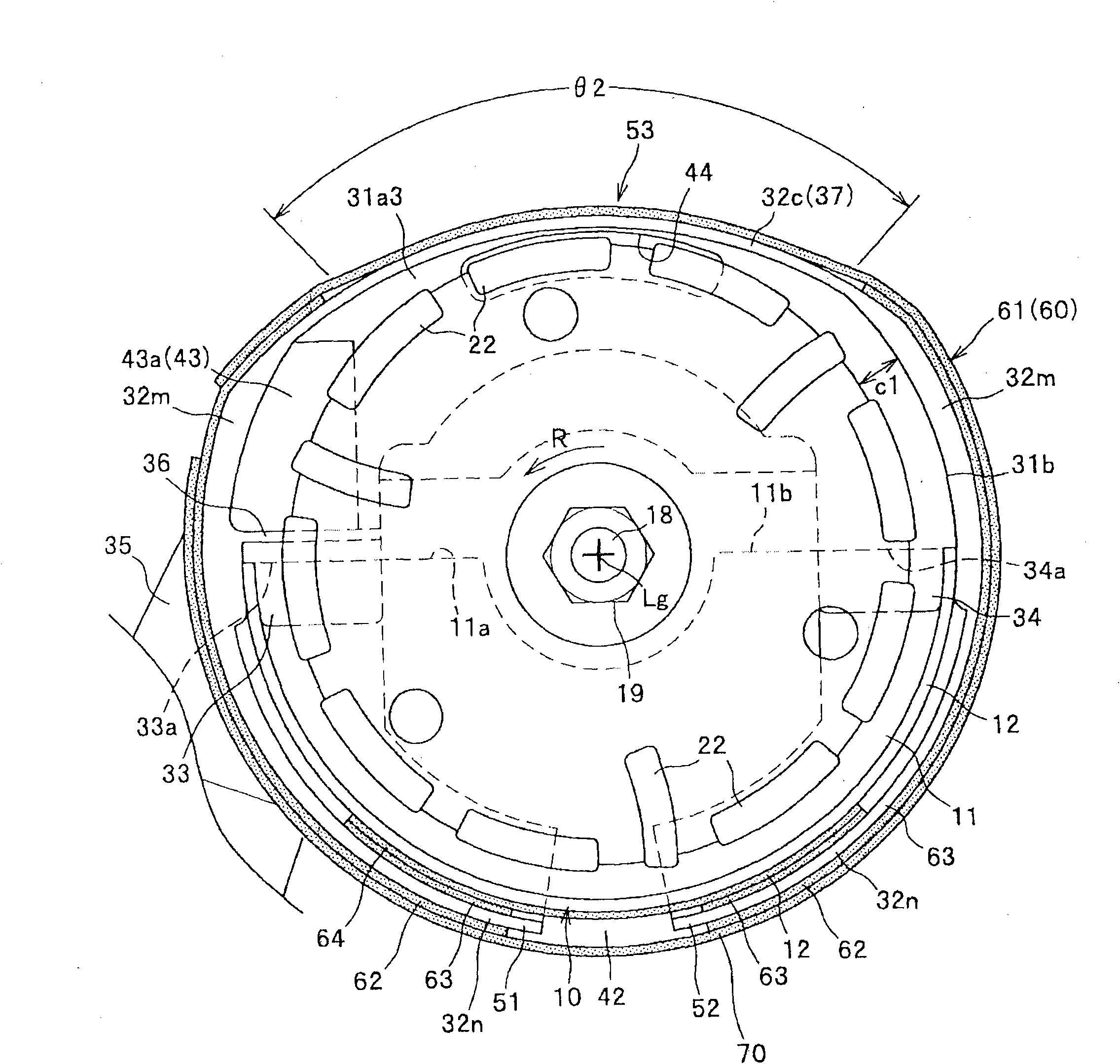

[0077] Embodiments of the dust cover structure of the present invention will be described below with reference to the drawings.

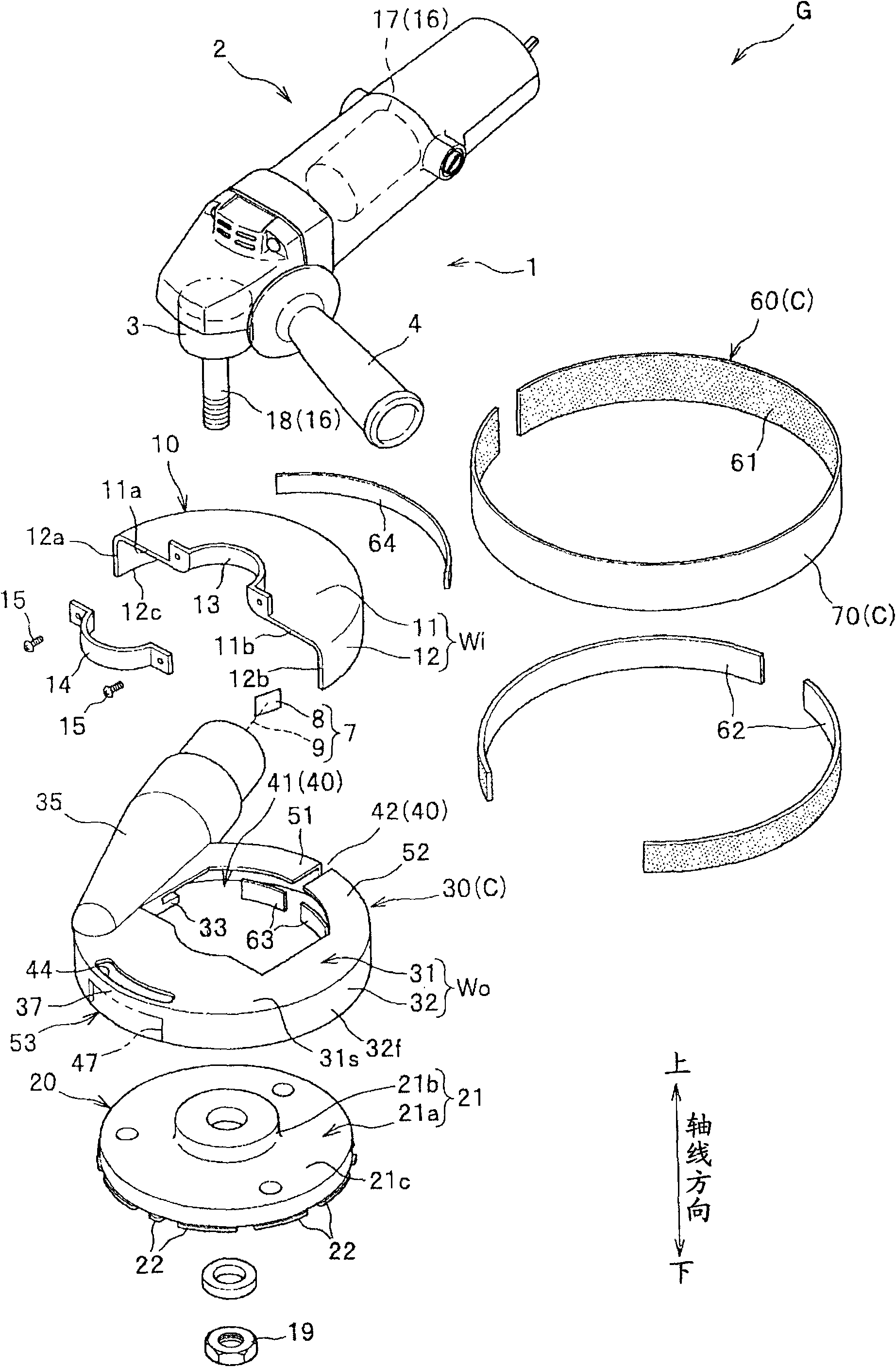

[0078] Such as figure 1 As shown, the grinding device G equipped with the dust cover structure C to which the present invention is applied uses the surface of the grinding object as a structure or article formed by forming materials such as concrete, metal, or synthetic resin as the surface to be ground. Bevel S1 (refer to Figure 4 (a)) Grinding is used, and the to-be-ground objects, such as a convex part, an attachment, and a coating film, are scraped off in this to-be-ground surface S1.

[0079] Such as Figure 1 ~ Figure 4 As shown in (a), the portable grinding device G includes: a main body 1 provided with a grip portion 4 held by an operator; 20 ; the driving device 16 provided on the main body 1 to rotationally drive the rotary grinding body 20 ; and the protective cover 10 as a cover support member provided on the main body 1 and detacha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com