Optical disc device

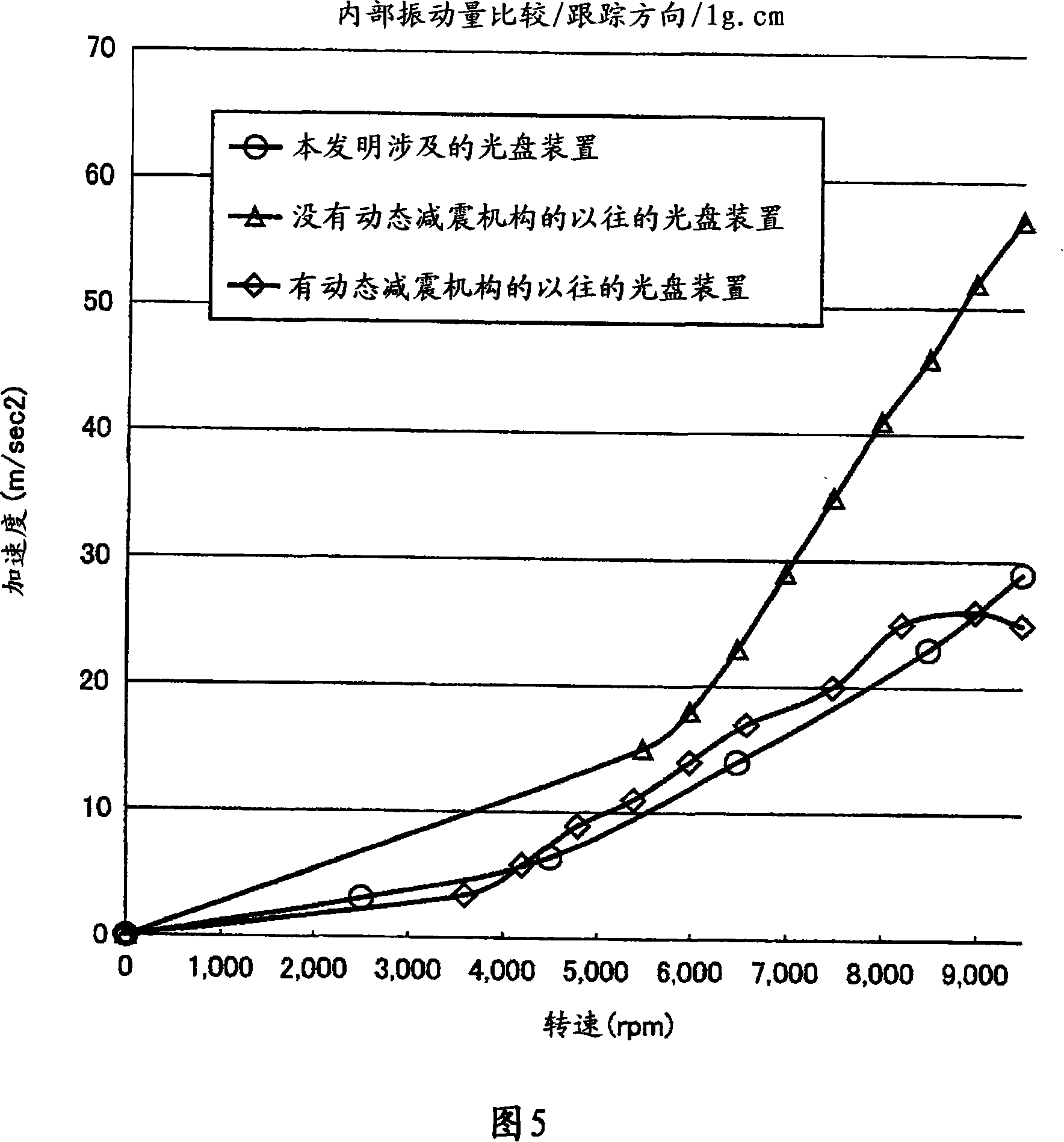

An optical disc device and optical disc technology are applied in the direction of planar recording carrier equipment, driving/moving recording head, poor vibration/sound insulation/absorption, etc., which can solve the problems of large characteristic changes and increased manufacturing costs, and achieve vibration suppression, The effect of reducing the number of parts and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

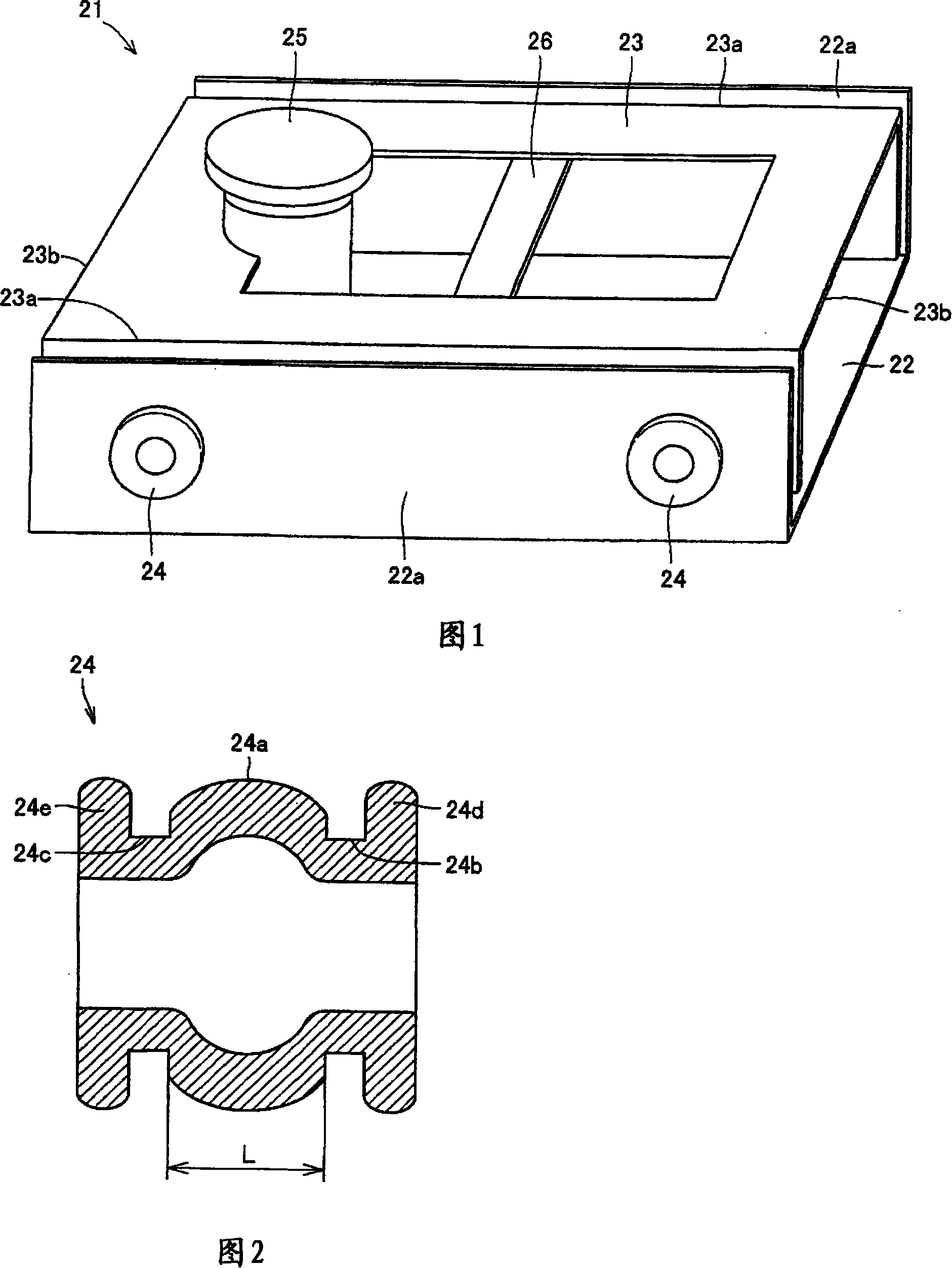

[0027] An optical disc device 21 according to an embodiment of the present invention will be described with reference to FIGS. 1 to 3 .

[0028] FIG. 1 is a perspective view of an optical disc device 21 . The optical disc device 21 includes: a casing 22 having a side wall 22 a ; a horizontal frame 23 ; and an elastic member 24 supporting the horizontal frame 23 on the casing 22 .

[0029] The horizontal frame 23 is rectangular including a pair of long sides 23a and a pair of short sides 23b, and supports a spindle motor 25 and an optical sensor holder 26 for driving an optical disk. The horizontal frame 23 is attached to the side wall 22a of the housing 22 from the horizontal direction by means of four elastic members 24 arranged at two places on each of the pair of long sides 23a.

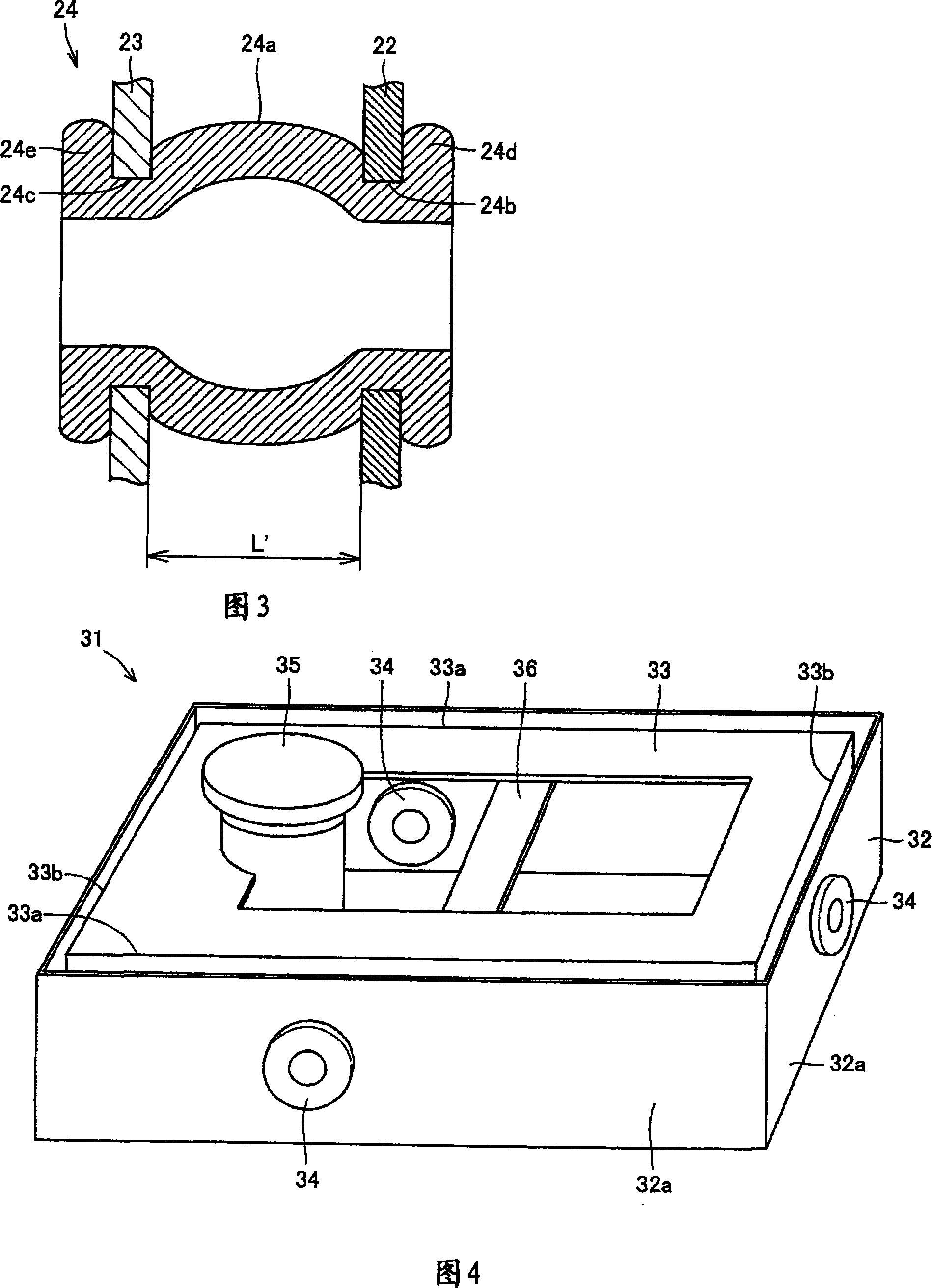

[0030] 2 and 3 are diagrams showing states of the elastic member 24 before and after installation. With reference to Fig. 2, elastic member 24 is cylindrical shape, and it comprises the cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com