Electric pressure cooker

A technology of electric pressure cooker and pressure relief valve, which is applied in the field of pressure cooker, can solve the problems of affecting product quality, limited pressure, easy to burn people, etc., and achieve the effect of accurate and fast signal transmission, sensitive pressure perception, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

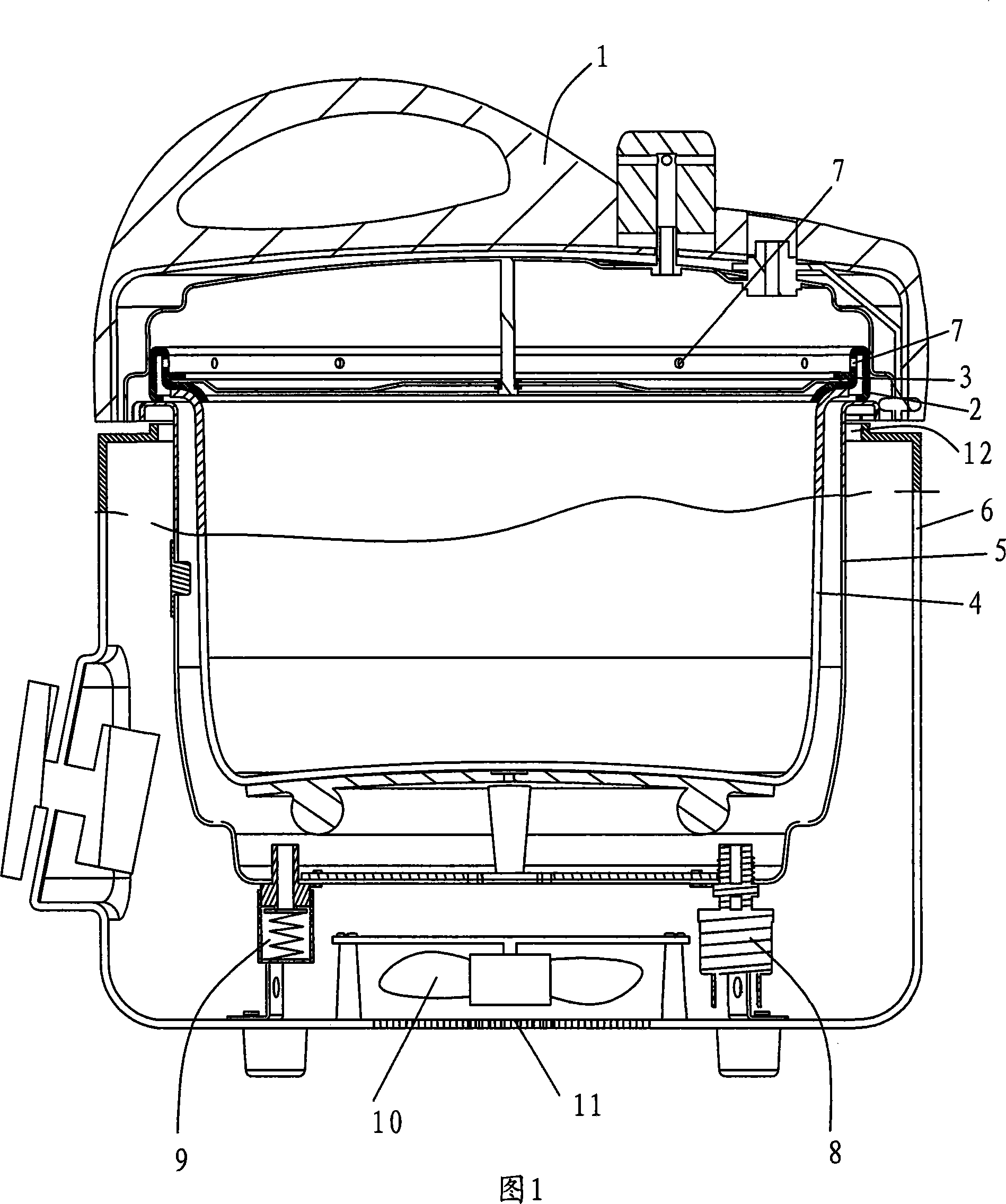

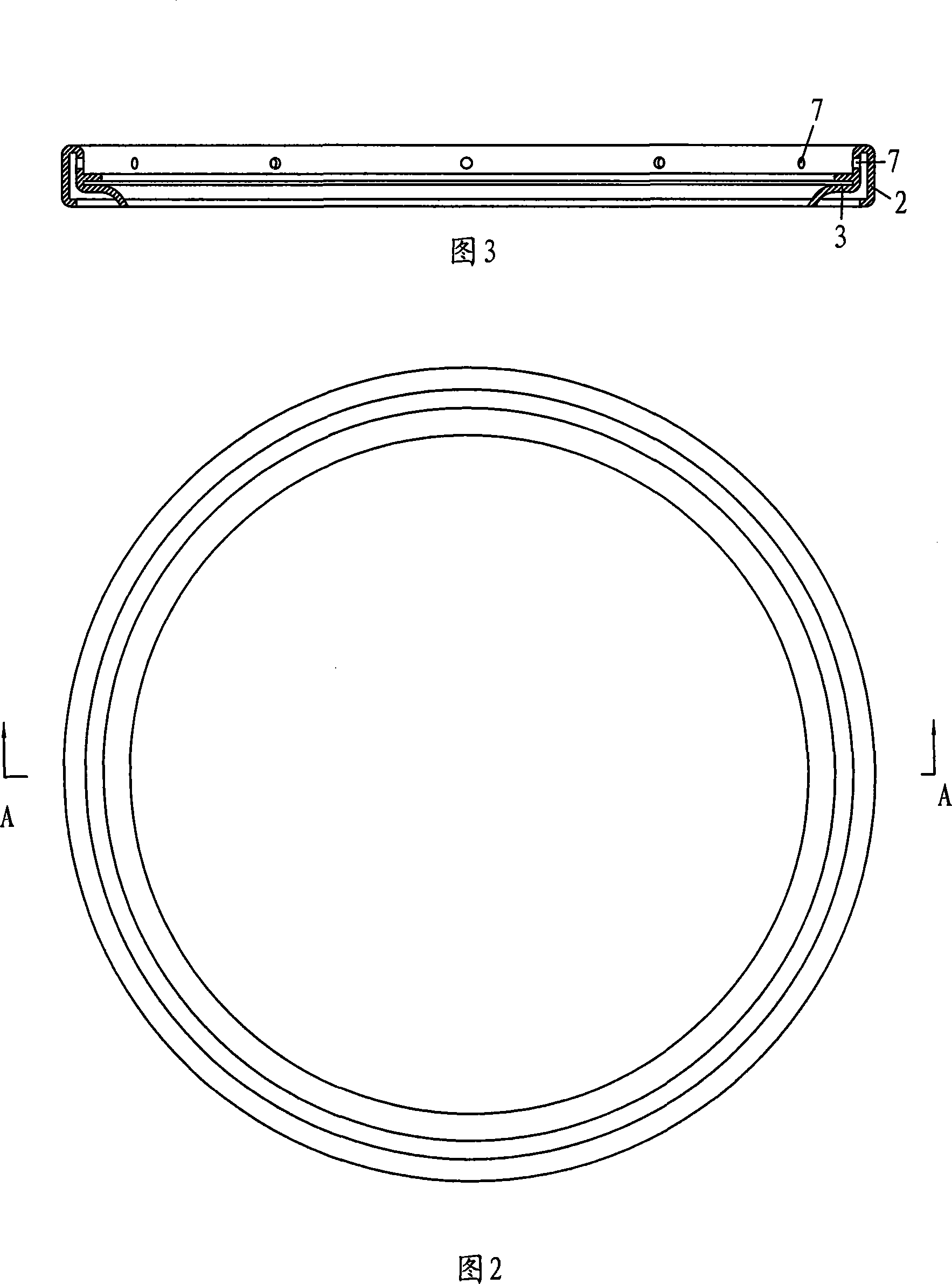

[0016] Embodiment, with reference to Fig. 1 to Fig. 3, a kind of electric pressure cooker, comprises upper cover 1, sealing ring 2, annular sealing ring 3, inner tank 4, outer tank 5, shell 6 and controller (not shown in the figure), The annular sealing ring 3 and the sealing ring 2 are a conjoined structure, the annular sealing ring 3 is located in the inner ring, the sealing ring 2 is located in the outer ring, the joint of the annular sealing ring 3 and the sealing ring 2 is provided with a steam hole 7, the sealing ring 2 and the annular The sealing ring 3 is installed on the upper cover 1 . After the upper cover 1 and the shell 6 are fastened together, the sealing ring 2 seals the upper cover 1 and the outer container 5 , and the annular sealing ring 3 and the inner container 4 seal fit. The steam of the inner bag 4 enters the outer bag 5 through the steam hole 7, so that the inner and outer walls of the inner bag bear the same pressure.

[0017] A pressure sensor 8 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com