Constant contact side bearing

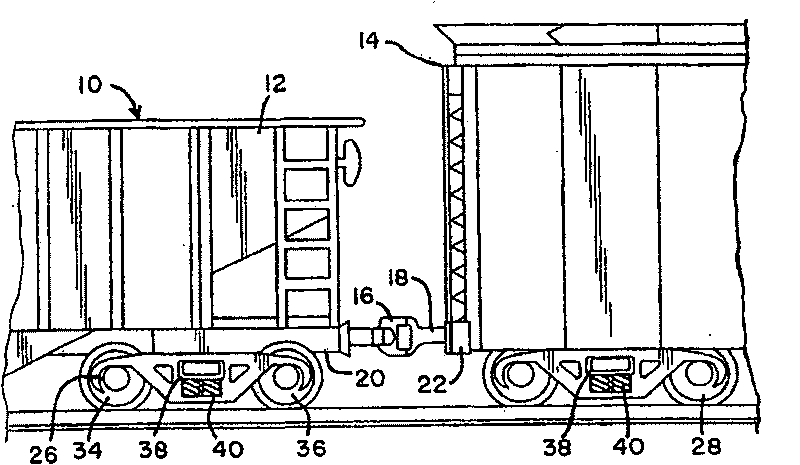

A side support, rated load technology, applied in the direction of the lateral relative movement between the underframe and the bogie, etc., can solve problems such as movement restrictions, and achieve the effect of improving the characteristics and life of the side support, long fatigue life, and weight saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

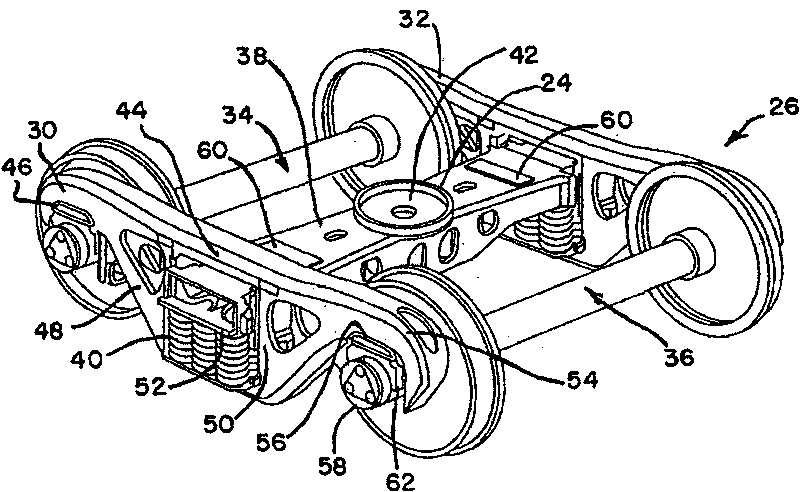

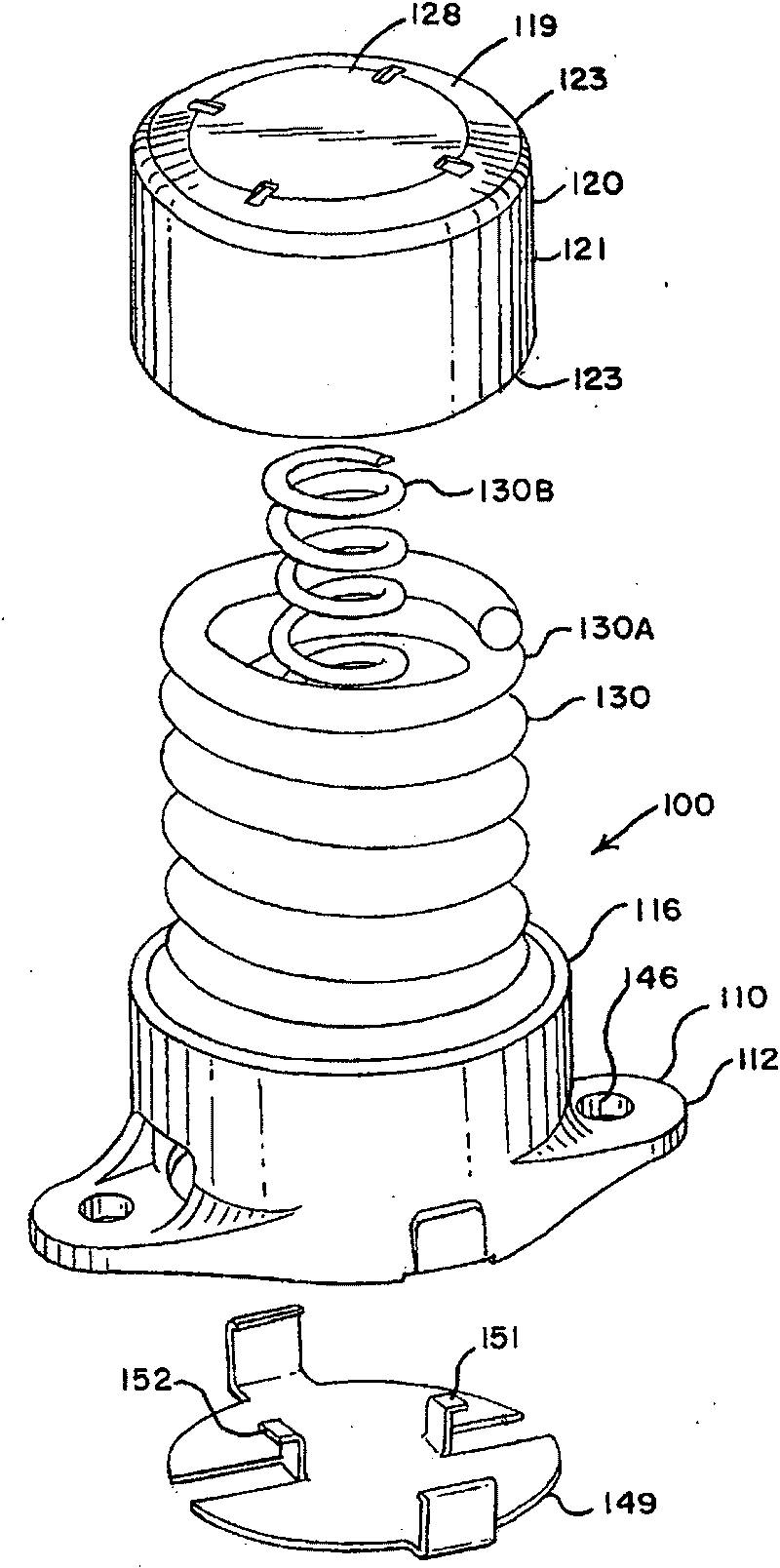

[0038] See below Figure 3-11 The first embodiment of the side support of the present invention will be described. The side support assembly 100 has a main longitudinal axis coincident with the longitudinal axis of the rail car. That is, when the side support is installed on the rail car bogie bolster 38, the main axis of the side support is perpendicular to the longitudinal axis of the bolster. The side support assembly 100 includes a base 110 as main elements, a cap 120, one or more elastic propulsion elements 130 (such as springs or elastomer elements), and a spring base 131. In the illustrated exemplary embodiment, two springs are provided, an outer spring 130A and an inner spring 130B used as a propulsion element, and each spring may have a different spring constant to provide a total combined rated load.

[0039] The base 110 is fixed to the bolster 38 with suitable devices. As shown in the figure, the base 110 is bolted to the bolster 38 with a mounting bolt (not shown) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com