Roller brake testing dynamometer

A technology of braking test and braking force, which is applied in the direction of measuring devices, vehicle testing, automobile tire testing, etc., can solve the problems of high complexity, cost, complex structure and configuration of the dynamometer, etc., and achieve reduced sensitivity and complex structure and the effect of expensive cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

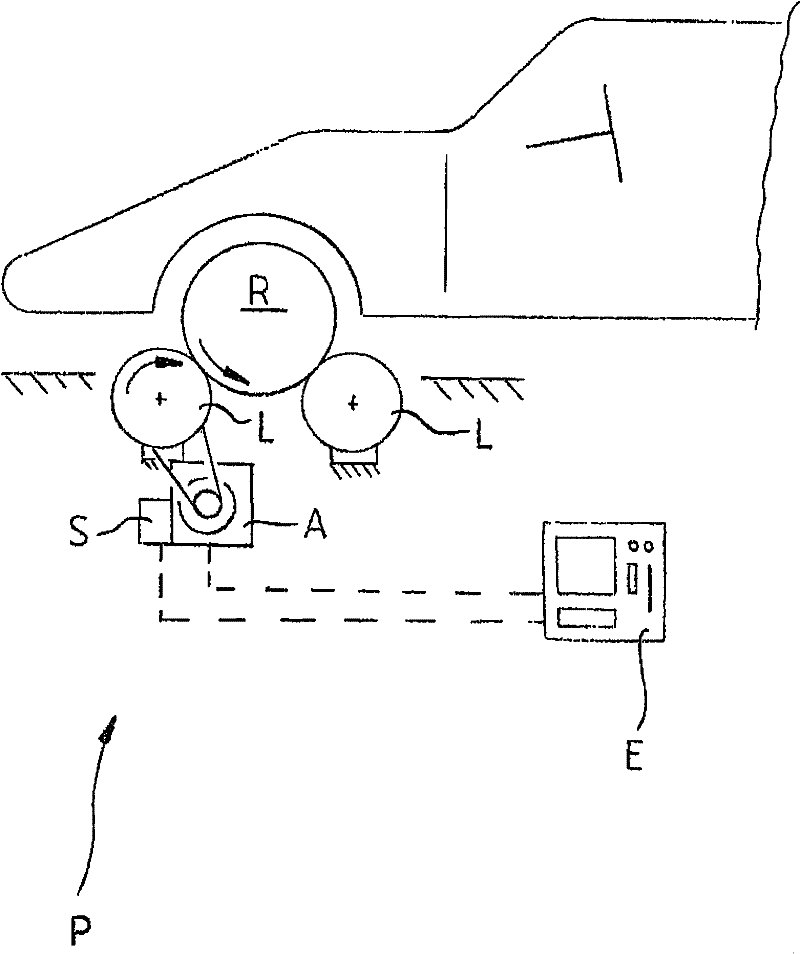

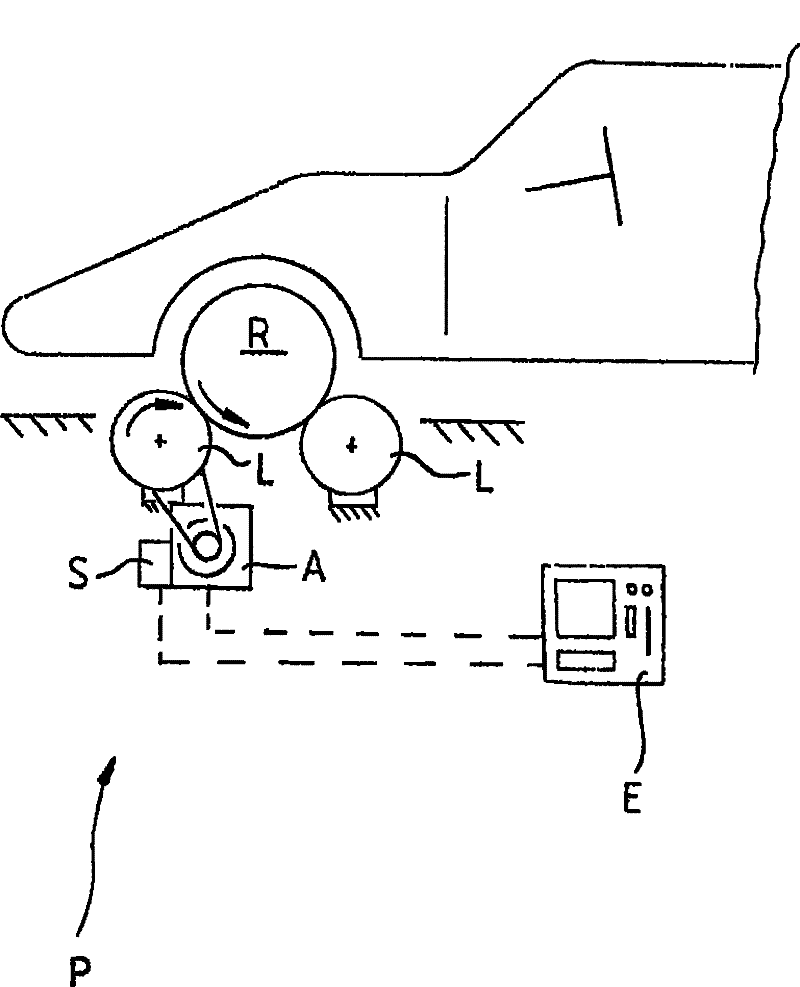

[0019] figure 1 is a side view of the setup where the wheels R of the vehicle rest on the two rollers L of the dynamometer P. figure 1 The drum L shown on the left side of is driven by the driver A shown in the figure to drive the tire R of the vehicle to rotate. In addition, a braking force sensor S is provided, which determines in a known manner the required driving force of the left-hand pulley L, or the resistance in the opposite direction.

[0020] The brake force sensor S and the drive A are connected to the evaluation and control unit E. Based on the input signal from the brake force sensor S, the control unit E outputs a control signal, which in particular includes a signal for switching off the drive A.

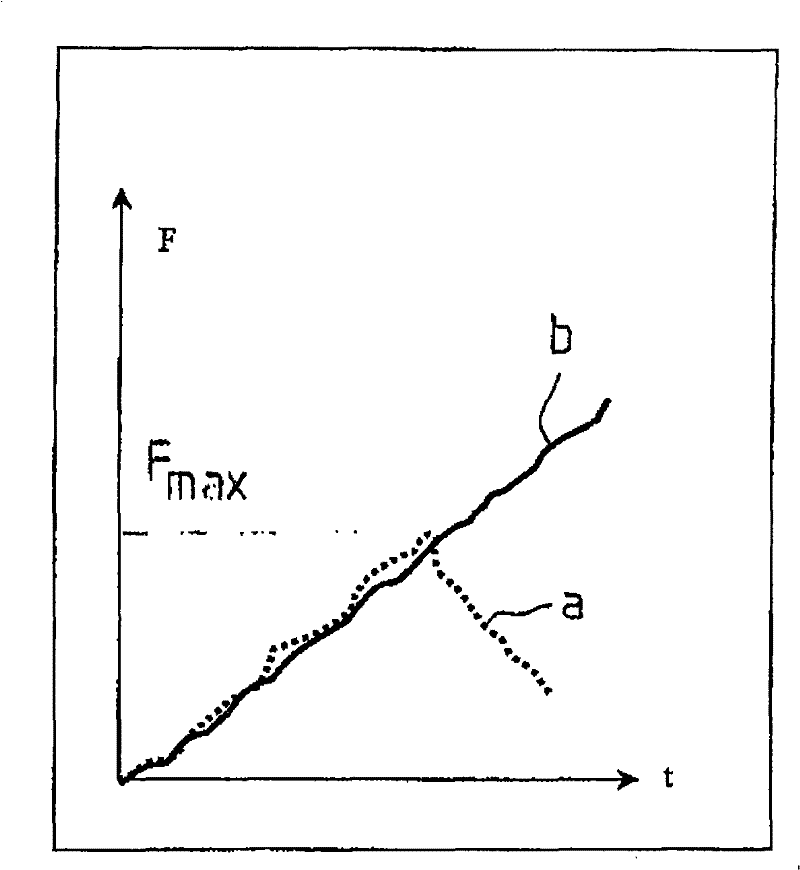

[0021] figure 2 A diagram showing the braking force profile of two vehicle tires being measured simultaneously in the braking test procedure described. In this case, the solid line "b" represents the graph of the braking force of the second tire as a function of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com