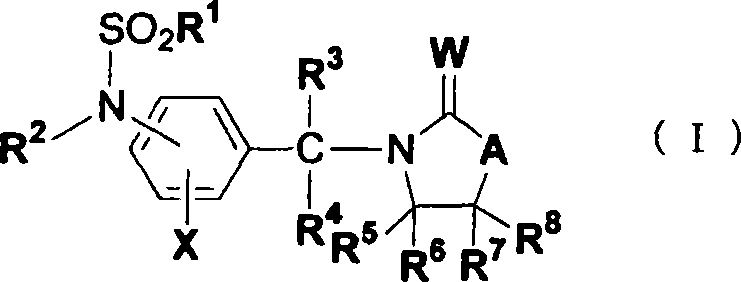

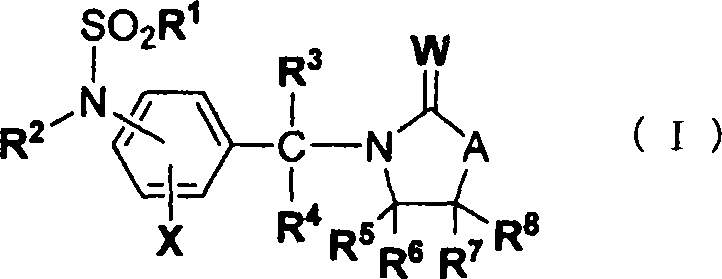

New haloalkylsulfonanilide derivative, herbicide and use method thereof

A technology of halogenated alkylsulfonanilides and alkylsulfonyl groups, which is applied in the field of novel halogenated alkylsulfonanilide derivatives or their salts, and can solve the problems of unknown preparation methods, physical and chemical properties and herbicidal activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

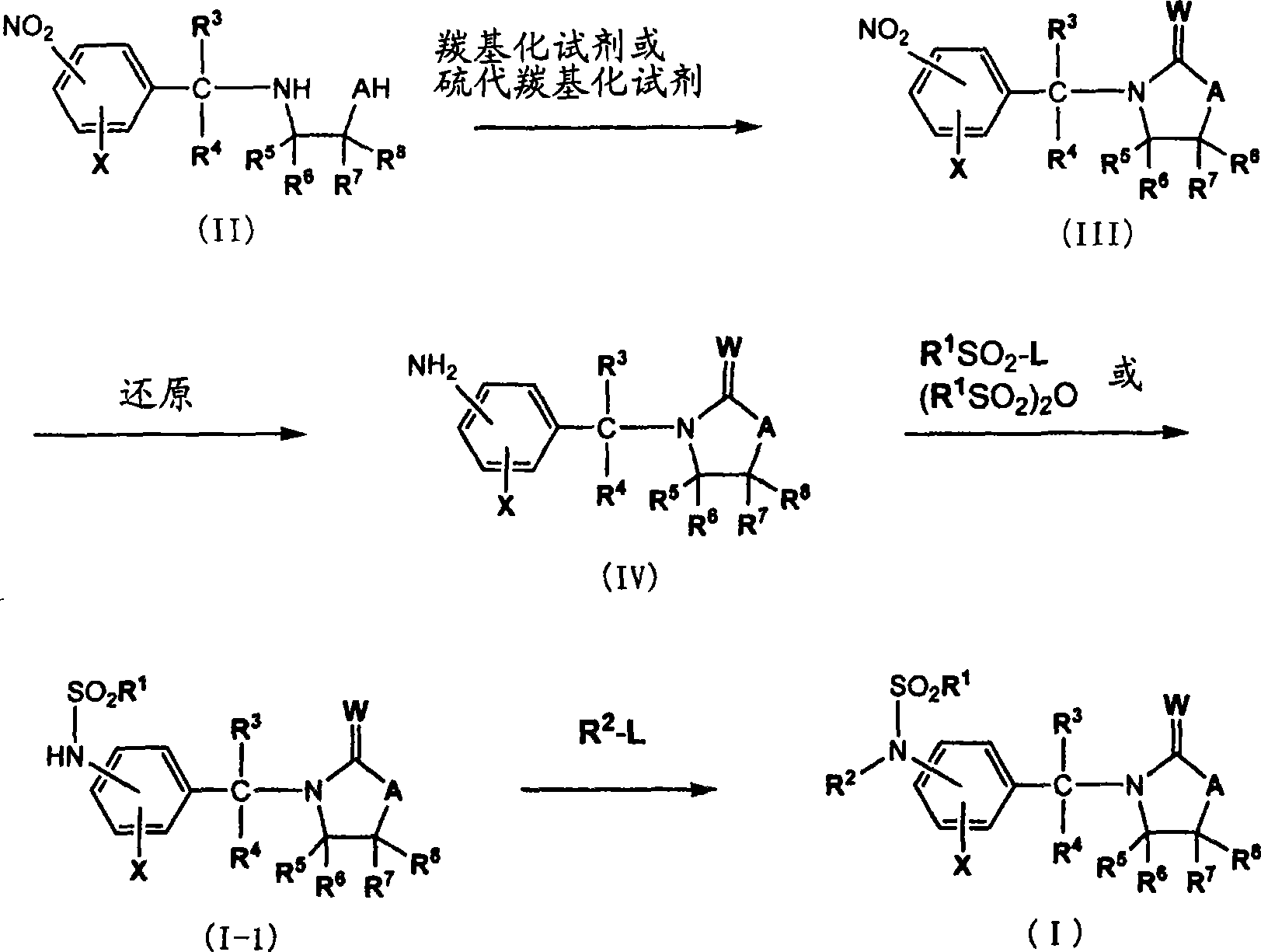

Method used

Image

Examples

Embodiment 1

[0196] Example 1. Preparation of 4-ethyl-3-[2-(trifluoromethanesulfonylamino)benzyl]-2-oxazolidinone (compound number 1-5)

[0197] 1-1) Preparation of 4-ethyl-3-(2-nitrobenzyl)-2-oxazolidinone

[0198] 2-(2-Nitrobenzylamino)-1-butanol (3.2 g, 14 mmol) was dissolved in chloroform (100 ml), and the reaction solution was cooled to 0°C. Next triethylamine (7.1 g, 71 mmol) and triphosgene (2.1 g, 7.1 mmol) were added. The reaction solution was stirred at 0°C for 1.5 hours, added with water and extracted with ethyl acetate. The ethyl acetate layer was washed with a saturated sodium chloride solution, dried over anhydrous magnesium sulfate, and the solvent was distilled off. The residue was purified by silica gel column chromatography (ethyl acetate:hexane=1:1) to give 4-ethyl-3-(2-nitrobenzyl)-2-oxazolidinone (2.6 g).

[0199] Yield: 72%

[0200] Nature: n D 1.5514(23℃)

[0201] 1-2) Preparation of 4-ethyl-3-(2-aminobenzyl)-2-oxazolidinone (Compound No. 2-2)

[0202]Dissolv...

Embodiment 2

[0209] Example 2. Preparation of 4-ethyl-3-{2-[N-(isobutoxycarbonyl)-N-(trifluoromethanesulfonyl)amino]benzyl}-2-oxazolidinone (Compound No. 1 -6)

[0210] 4-Ethyl-3-[2-(trifluoromethanesulfonylamino)benzyl]-2-oxazolidinone (1.0 g, 2.8 mmol) and sodium bicarbonate (0.48 g, 5.7 mmol) were suspended in acetonitrile (10ml), add isobutyl chloroformate (0.78g, 5.7mmol), and reflux for 2 hours. The reaction solution was cooled to room temperature, and extracted with ethyl acetate after adding water. The ethyl acetate layer was washed with a saturated sodium chloride solution, dried over anhydrous magnesium sulfate, and the solvent was distilled off. The residue was purified by silica gel column chromatography (ethyl acetate:hexane=1:2) to give 4-ethyl-3-{2-[N-(isobutoxycarbonyl)-N-(trifluoromethanesulfonyl) Amino]benzyl}-2-oxazolidinone (1.2 g).

[0211] Yield: 91%

[0212] Properties: Melting point 69.3-71.7℃

Embodiment 3

[0213] Example 3. Preparation of 4,4-dimethyl-3-[2-(trifluoromethanesulfonylamino)benzyl]-2-oxazolidinone (compound number 1-15)

[0214] 3-1) Preparation of 4,4-dimethyl-3-(2-nitrobenzyl)-2-oxazolidinone

[0215] 2-(2-nitrobenzylamino)-2-methyl-1-propanol (2.6g, 12mmol) was dissolved in chloroform (100ml), and the reaction solution was cooled to 0°C, then triethylamine (5.9g , 59mmol) and triphosgene (1.7g, 5.9mmol). The reaction solution was stirred at this temperature for 1.5 hours, and extracted with ethyl acetate after adding water. The ethyl acetate layer was washed with a saturated sodium chloride solution, dried over anhydrous magnesium sulfate, and the solvent was distilled off. The residue was purified by silica gel column chromatography (ethyl acetate:hexane 1:1) to give 4,4-dimethyl-3-(2-nitrobenzyl)-2-oxazolidinone (1.3 g).

[0216] Yield: 43%

[0217] Properties: Melting point 103-106℃

[0218] 3-2) Preparation of 4,4-dimethyl-3-(2-aminobenzyl)-2-oxazolidino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com