Universal wrench

A wrench and wrench head technology, applied in the field of wrenches, can solve the problems of increased construction difficulty, prolonged construction time, insufficient bolt tightening, etc., to achieve the effects of improving labor efficiency, shortening construction time, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

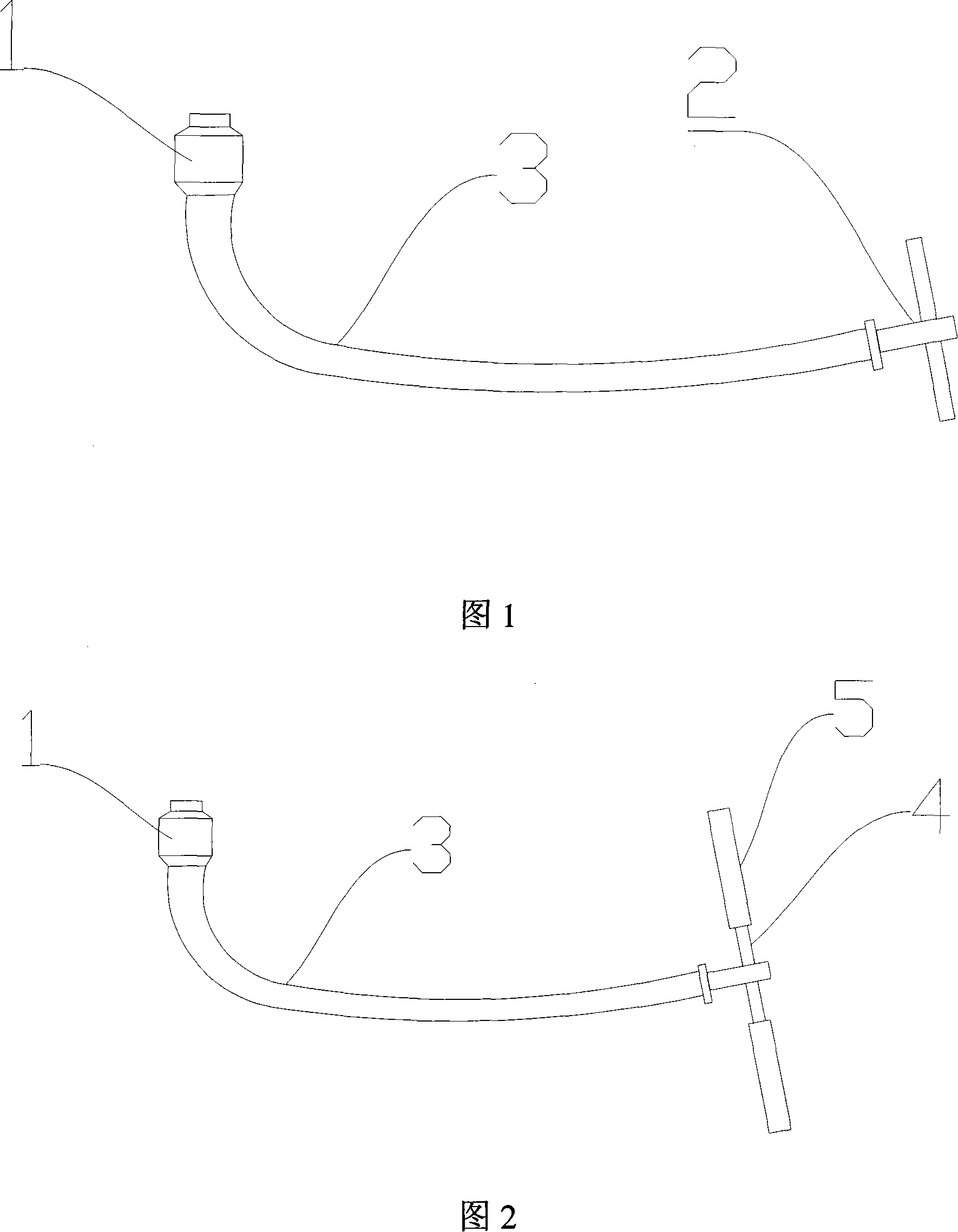

[0015] The first embodiment, as shown in Fig. 1, a universal wrench includes a wrench 1 and a handle 2. The wrench 1 and the handle 2 are respectively installed at both ends of a flexible shaft, the wrench 1 is a sleeve, and the wrench 1 It is detachably connected with the flexible shaft, and the flexible shaft is covered with a sleeve 3.

[0016] The second embodiment, as shown in Figure 2, the universal wrench includes a wrench 1 and a shaft 4, the shaft 4 is sleeved with a sleeve 5, and the wrench 1 and the shaft 4 are respectively mounted on two flexible shafts that can be bent. At the end, the wrench 1 is a sleeve, and the wrench 1 is detachably connected with the flexible shaft, and the flexible shaft is covered with a sleeve 3. When in use, sleeve the shaft sleeve 5 on the shaft 4, and the shaft sleeve 5 and the shaft 4 together serve as a handle to increase the length of the grip part, which is more convenient to use; after use, the shaft sleeve 5 can be removed.

no. 3 example

[0017] In the third embodiment, on the basis of the second embodiment, positioning marbles and positioning holes are provided at the socket joint of the shaft 4 and the shaft sleeve 5 to movably connect the shaft 4 and the shaft sleeve 5 together. When in use, the length of the grip part can be increased after pulling the shaft sleeve 5, which is convenient to use. After use, press the shaft 4 into the shaft sleeve 5 to avoid taking up too much space

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com