Hinge pin connector for tower crane

A tower crane and pin shaft technology, applied in the directions of cranes, bolts, etc., can solve the problems of obstructing the transportation and movement of tower cranes, inconvenient transportation of fixed pin connectors, too large and too long pin shafts, etc., so as to solve the problem of installation and disassembly. , The structure is simple and reliable, and the effect of the pin shaft being too long is solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

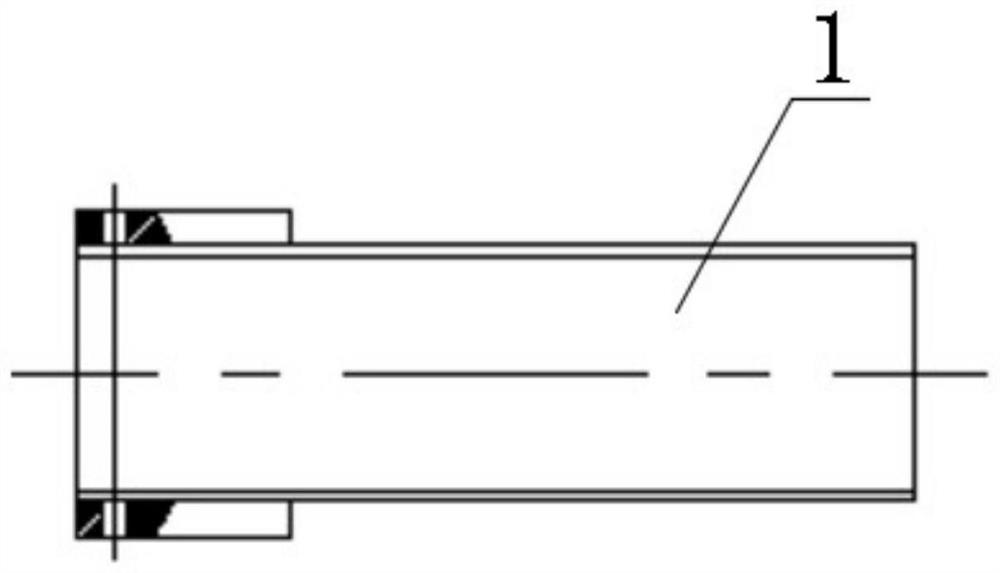

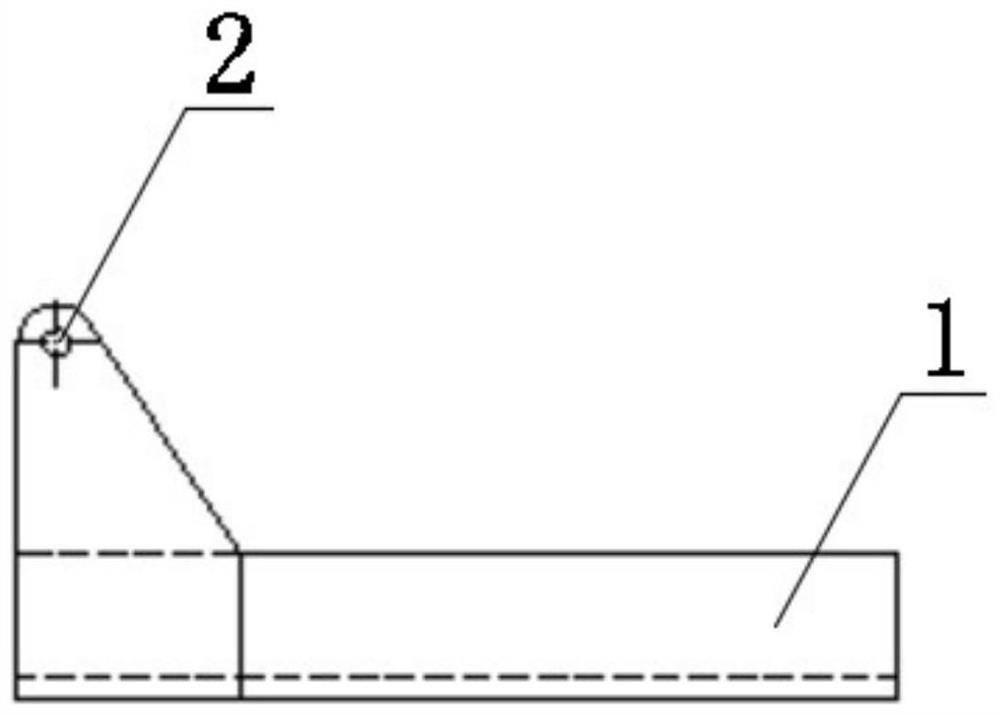

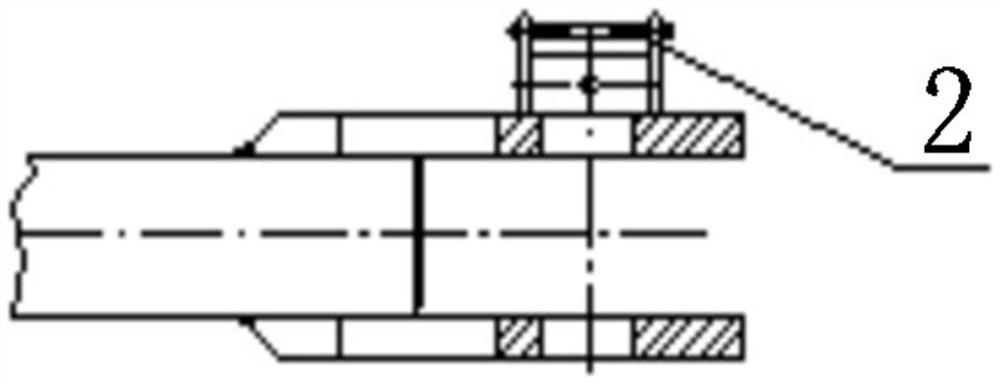

[0027] Such as Figure 1 to Figure 5 As shown, the present invention is a pin connector for a tower crane, comprising a base 1, the base 1 is a cuboid through groove, one end of the base 1 is fixedly connected with a pair of connecting plates 2, and the connecting plates 2 are symmetrically arranged on Both sides of the base 1, the top of the connecting plate 2 is provided with a pin hole, the side of the connecting plate away from the base 1 is fixedly connected with a support plate 3, the support plate 3 is a flat plate, and the other end of the support plate 3 is connected to the Tower crane fixed connection;

[0028] Further, the height of the base 1 is lower than the height of the connecting plate 2;

[0029] Further, the top of the connecting plate 2 is arc-shaped;

[0030] Further, the thickness of the connecting plate 2 is the same as that of the side wall of the base 1;

[0031] As preferred, the base 1 is channel steel;

[0032] Preferably, the connecting plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com