Integrated proppant flat plate conveying experimental device and preparation method thereof

An experimental device and proppant technology, applied in the field of hydraulic fracturing, can solve the problems of complex installation and disassembly of flat plates and cannot be covered, and achieve the effects of high production efficiency, easy operation, and avoiding installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

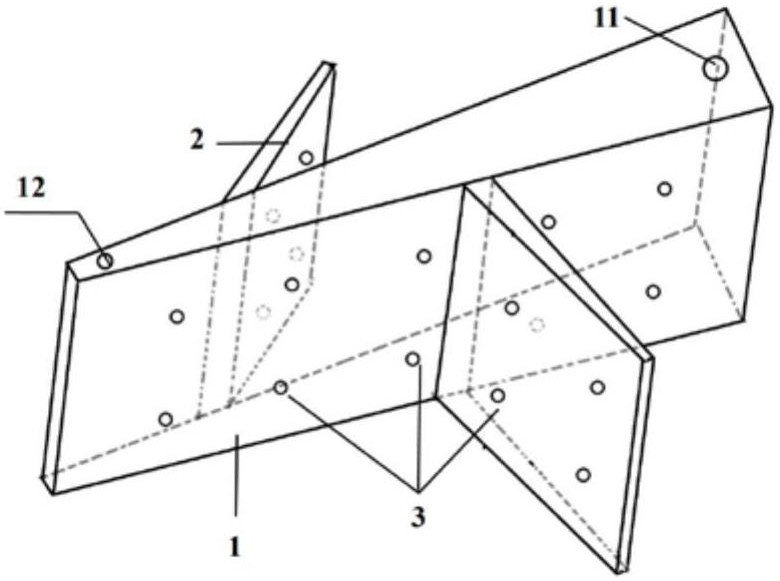

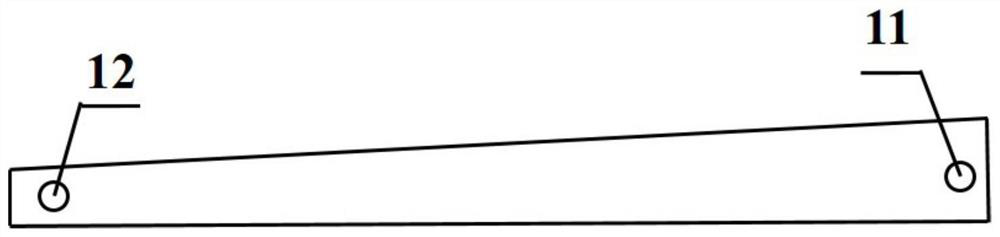

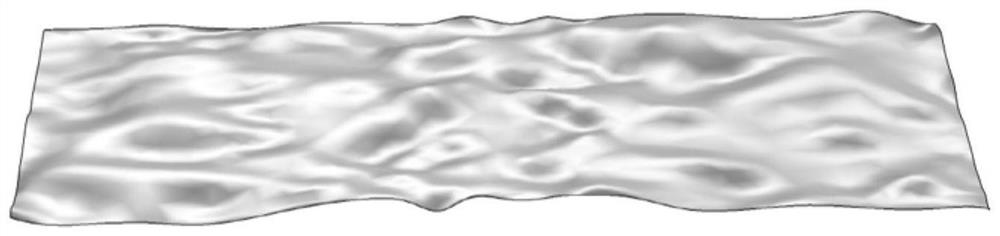

[0045] In the existing proppant slab transport experiments, multiple factors such as fracturing fluid loss, fracture roughness, number and angle of secondary fractures, variable fracture width, etc. cannot be considered together, and the existing proppant slab support device needs to be installed and disassembled , in order to solve the above problems, the present invention and the embodiments of the present invention provide a kind of integrated proppant plate conveying experimental device, such as figure 1 As shown, it includes a main artificial fracture unit 1, two secondary artificial fractures 2, and a fracture filtration unit 3; the main artificial fracture unit and the secondary artificial fracture unit are composed of plexiglass plates, and the plexiglass plates are of an integrated structure , presenting a continuous, integral and multi-branched spatial form;

[0046] The plexiglass plate of the main artificial crack unit is 1m long, 0.1m high, and has a maximum thick...

Embodiment 2

[0053] The present invention also provides a method for preparing an integrated proppant plate delivery experimental device, comprising the following steps:

[0054] (1) According to the fracture shape simulated by the fracturing software, design and prepare the mold required for the production of the plate;

[0055] (2) Prepare 3L of methyl methacrylate monomer and 5g of initiator in a flask, dissolve the two by magnetic stirring, raise the temperature of the system to 80°C through an electric heating mantle, and observe that the viscosity of the system increases to gel After the shape, the heating was stopped, and the prepolymer was obtained after rapid cooling to room temperature.

[0056] (3) Evenly and slowly pour half the volume of the prepolymer obtained in the previous step into the mold, and continue to polymerize the prepolymer in the mold at a temperature of 55 ° C. The polymerization reaction time is 3-4 hours, until the material in the mold is Hard gelatinous sol...

Embodiment 3

[0061] When using the integrated proppant plate transport experimental device of the present invention, the experiment needs to be carried out through the following steps:

[0062] (1) According to the similar principle and based on the site hydraulic fracturing construction design data, the proppant dosage required for the calculation experiment is 80g, the fracturing fluid volume is 800ml, and the fracturing fluid displacement is 30ml / min;

[0063] (2) Prepare fracturing fluid and prepare multiple proppants according to the materials required for the experiment calculated in step (1);

[0064] (3) select the 40-70 purpose quartz sand proppant in the step (2) to mix and stir with the guar gum fracturing fluid, and pump the sand-carrying fracturing fluid into the liquid inlet of the experimental device;

[0065] (4) Track the migration trajectory of the proppant in the main artificial fracture unit and the secondary artificial fracture unit, collect the fluid lost by guar gum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com