Method to reduce microwave plasma excitated difficulty

A microwave plasma, difficult technology, applied in the direction of plasma, electrical components, etc., can solve the problems of limited plasma volume, unsuitable for industrial needs, low cavity quality factor, etc., to achieve practical application promotion, difficulty reduction, discharge easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

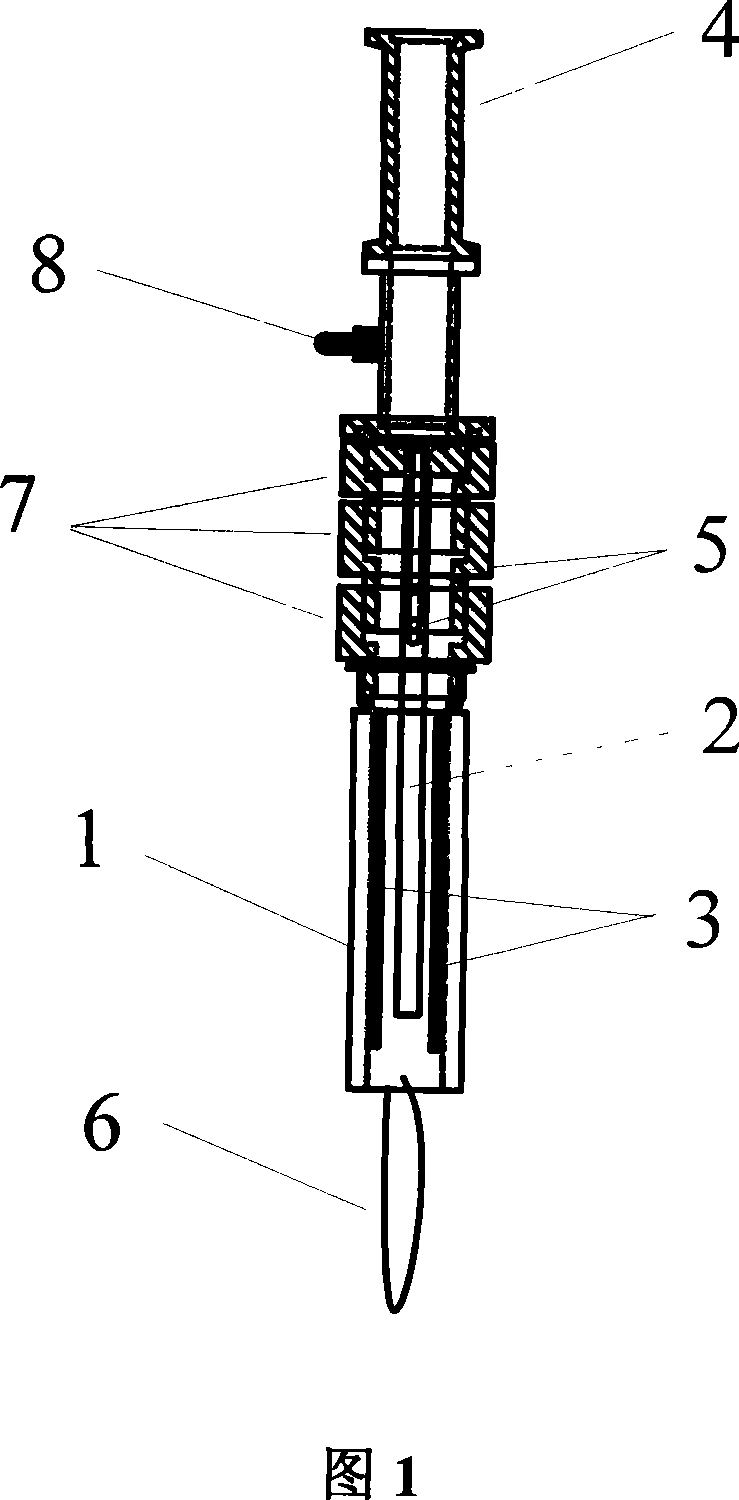

[0020] The structure of the ionization tube used in this embodiment is a coaxial electrode type, as shown in Figure 1, and its composition includes: an insulated air inlet nozzle tube 4 is connected to the inner electrode 2, the lower end of the inner electrode 2 is a solid metal rod, and the upper end is hollow and open. There are air holes 5, and the outer coat is covered with an insulating and airtight layer 7, so that the gas passes through them and enters the coaxial electrode area. The outer electrode 1 is a hollow metal cylinder that covers the lower part of the inner electrode. The distance between the two electrodes generally does not exceed 1cm. , with a dielectric barrier layer 3 . Wherein, the inner electrode is connected to the power supply through the power connector 8, and the outer electrode is grounded.

[0021] The action mode of the jet ioni...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap