Pressure generation device

A technology for generating device and pressure, applied in transportation and packaging, piston pump, liquid variable capacity machinery, etc., can solve the problem of difficulty in reducing the size of the pressure generating device, and achieve the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

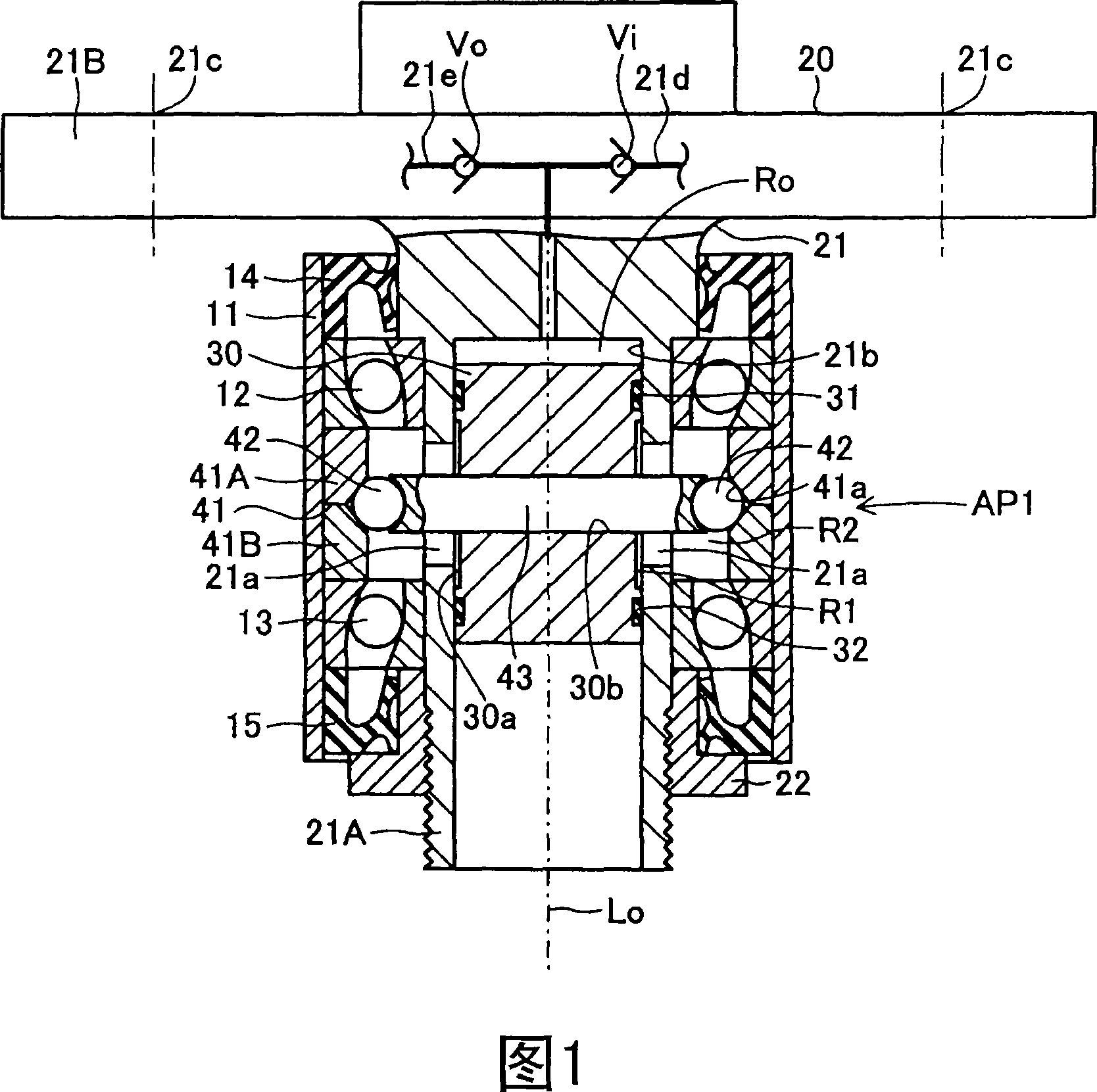

[0025] Embodiments of the present invention will be described below with reference to the drawings. Figure 1 shows a first embodiment of a pressure generating device according to the invention. The pressure generating device AP1 of the first embodiment can supply pressurized air to a tire cavity (not shown) of a wheel of a vehicle. The pressure generating device AP1 includes: a cylindrical support portion 11 serving as a supporting member and as a part of a steering knuckle; an axle hub 20 serving as a rotating member; a cylindrical piston 30 serving as a pumping member; a cam member 41 and two cam follower members. moving member 42, which cooperatively serves as a motion conversion mechanism for converting the rotational motion of the axle hub 20 relative to the cylinder support portion 11 into a reciprocating motion (vertical motion in FIG. 1 ) of the piston 30; and a rod 43, which The cam follower 42 is rotatably supported.

[0026] The cylindrical support portion 11 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com