Rolling element accommodating belt, linear guide apparatus and metallic mold for manufacturing rolling element accommodating belt

A technology of rolling elements and metal molds, applied to bearing elements, mechanical equipment, linear motion bearings, etc., can solve the problems of increased manufacturing costs and achieve stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

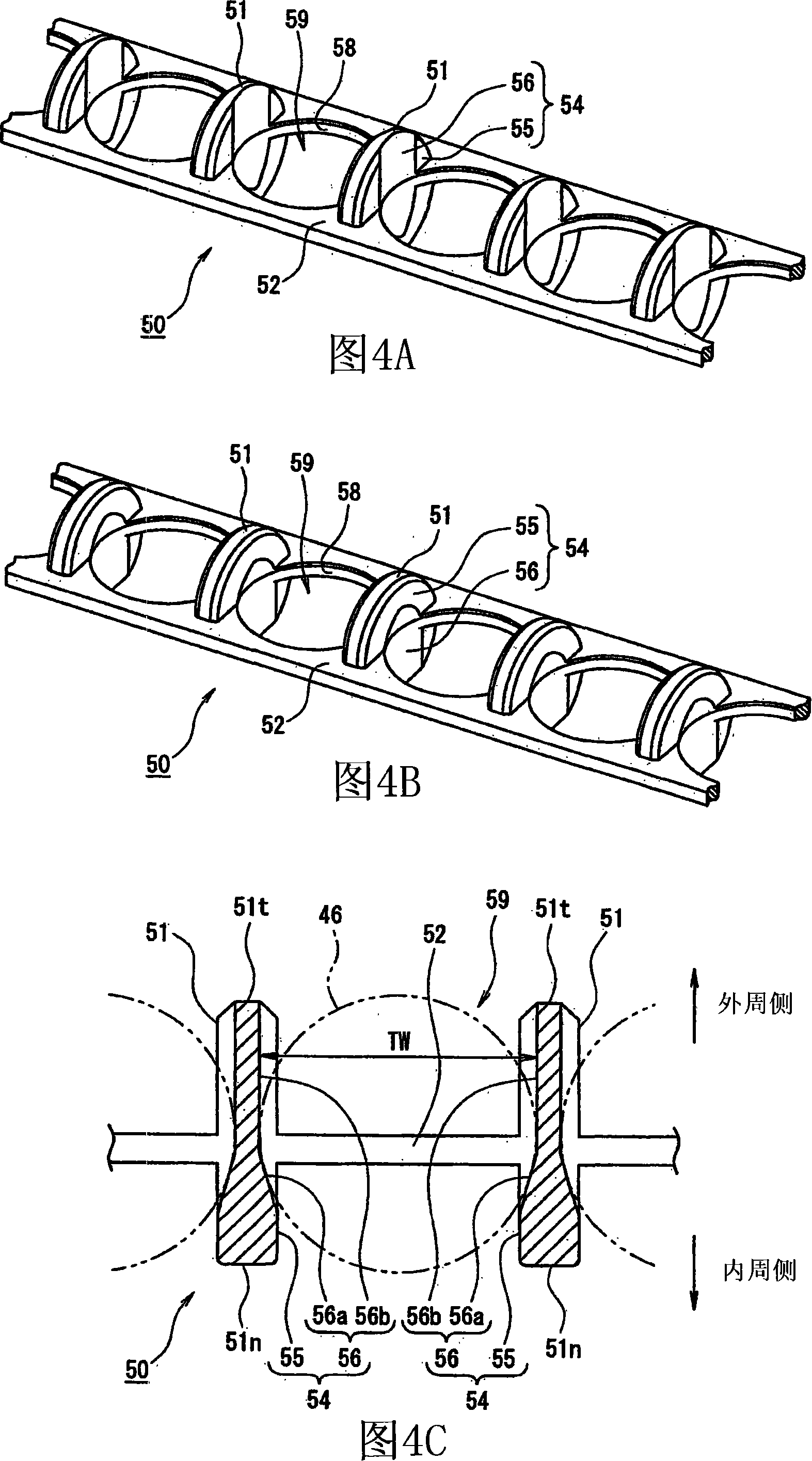

[0094] First, a first embodiment of the present invention according to the first to fifth aspects of the present invention will be described.

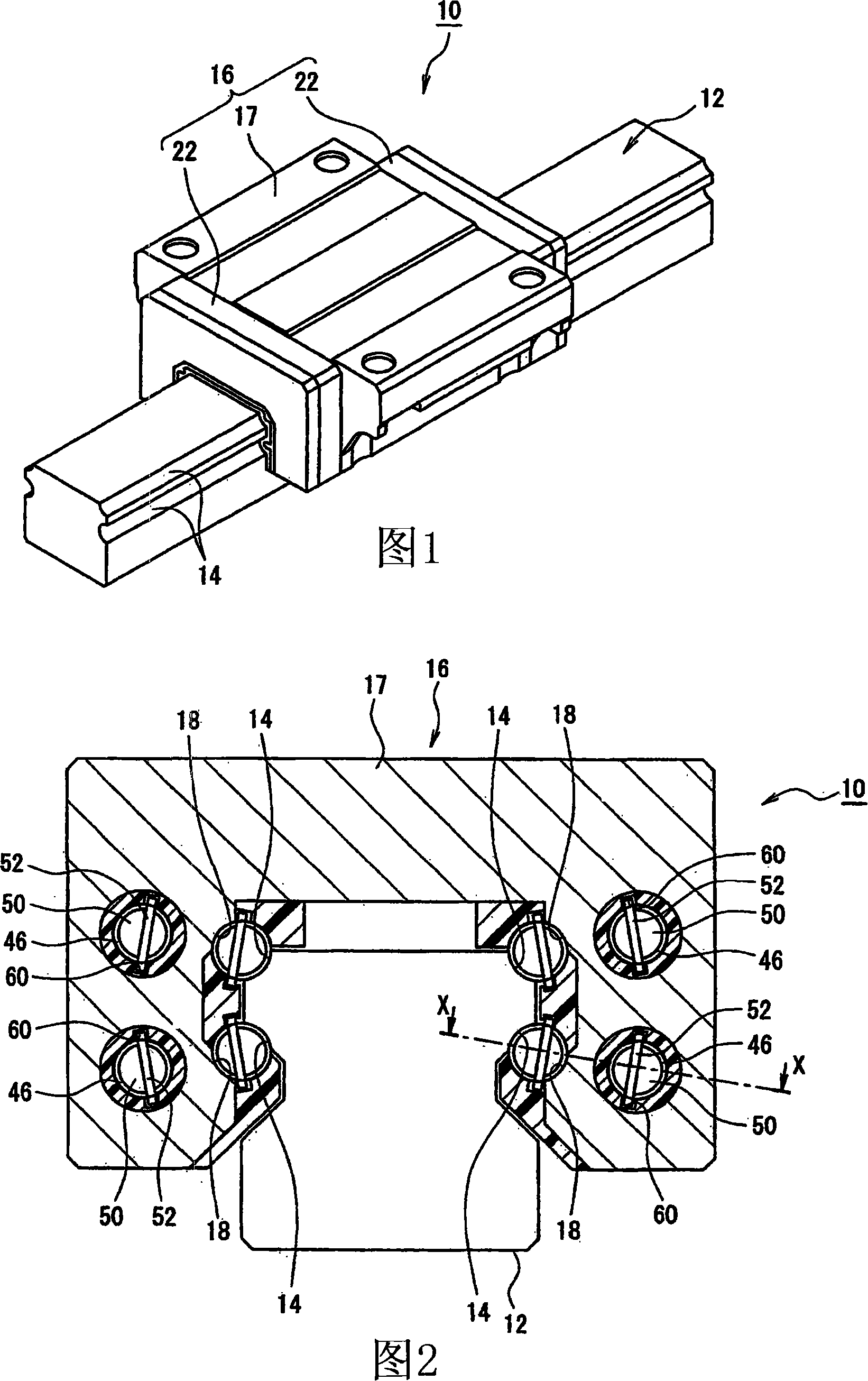

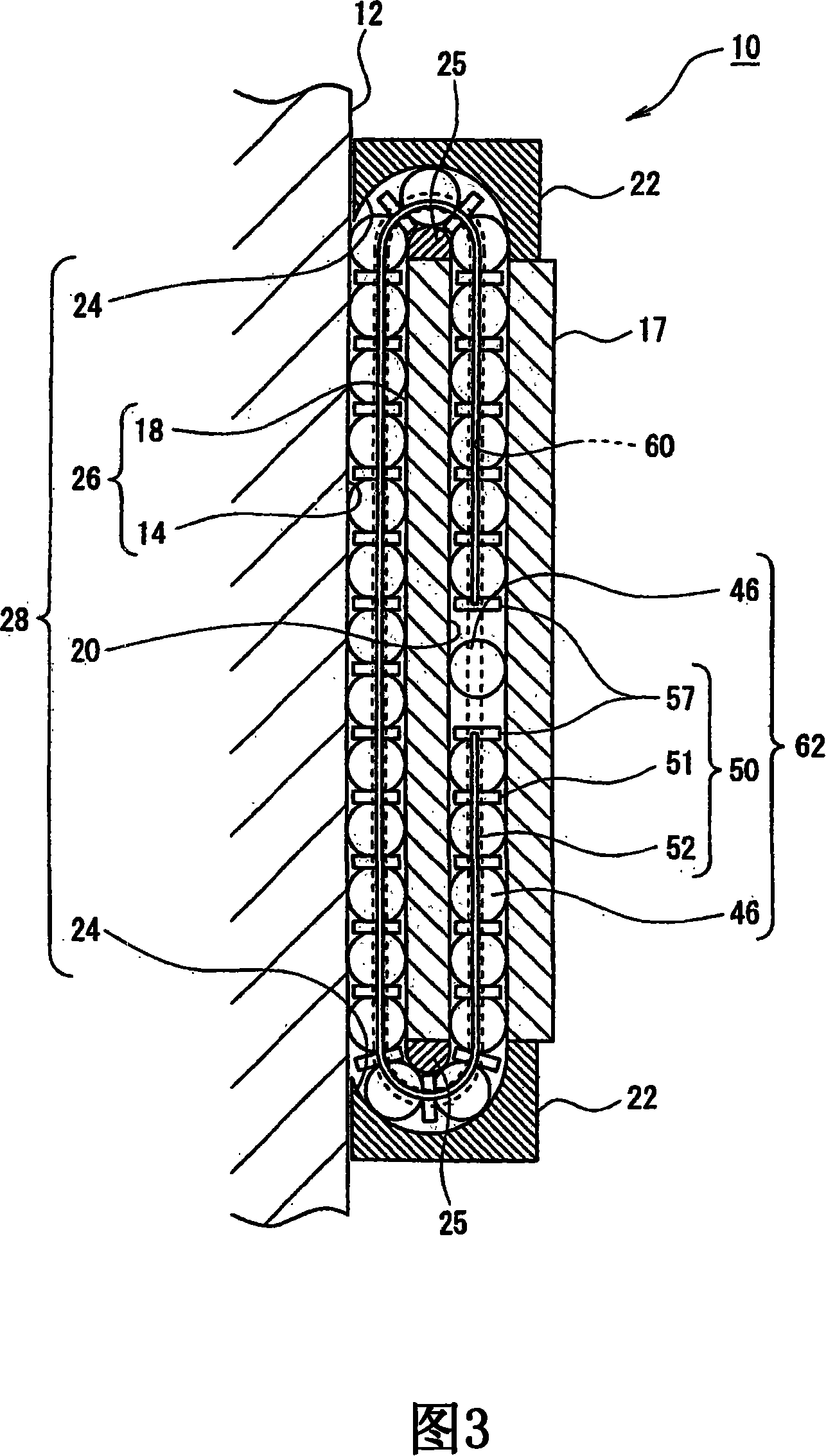

[0095] FIG. 1 is a perspective view of a linear guide showing a first embodiment of a linear guide apparatus having a rolling element accommodating belt of the present invention. Figure 2 is a front view showing the linear guide of Figure 1 with the end cap removed from the linear guide. Fig. 3 is a sectional view taken along the line X-X of the linear guide shown in Fig. 2 .

[0096] As shown in FIGS. 1 and 2, the linear guide 10 includes: a guide rail 12 having a rolling element guide surface 14; and a slider 16 mounted on the guide rail 12 so that the slider 16 can move relative to the guide rail 12. .

[0097] The guide rail 12 has a substantially square cross-section. On both sides of the guide rail 12, four rolling element guide surfaces 14 are provided, that is, two rolling element guide surfaces 14 are provided on one side o...

no. 2 example

[0142] Next, second and third embodiments according to the sixth to eleventh aspects of the present invention will be described.

[0143] The basic structures of the rolling element accommodating belt, the linear guide device, and the metal mold are the same, and detailed descriptions about similar members will be omitted.

[0144] As shown in Figures 13B and 13C, the boundary position PL is set at the position of the boundary between the non-contact surface 155 and the contact surface 156 of each spacer part 151, and the product structure 193 of the upper mold 191 and the lower mold 192 is on the boundary. Demarcation at position PL. As shown in FIG. 14 , in this metal mold 190 , a pouring port 194 for pouring molten synthetic resin into a product structure portion 193 is provided in a lower mold 192 . At positions corresponding to the ends on the inner peripheral side of the spacer portion 151 to be formed, a necessary number of pouring ports 194 are provided. In the examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com