Co-cr-pt-b alloy sputtering target and method for producing same

A manufacturing method and a sputtering target technology, which are applied in sputtering coating, sputtering coating, disc carrier manufacturing, etc., can solve problems such as microcracks that are not recorded, and achieve prevention or suppression of nodules or The effects of particle generation, high leakage flux density, fine and uniform rolling structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

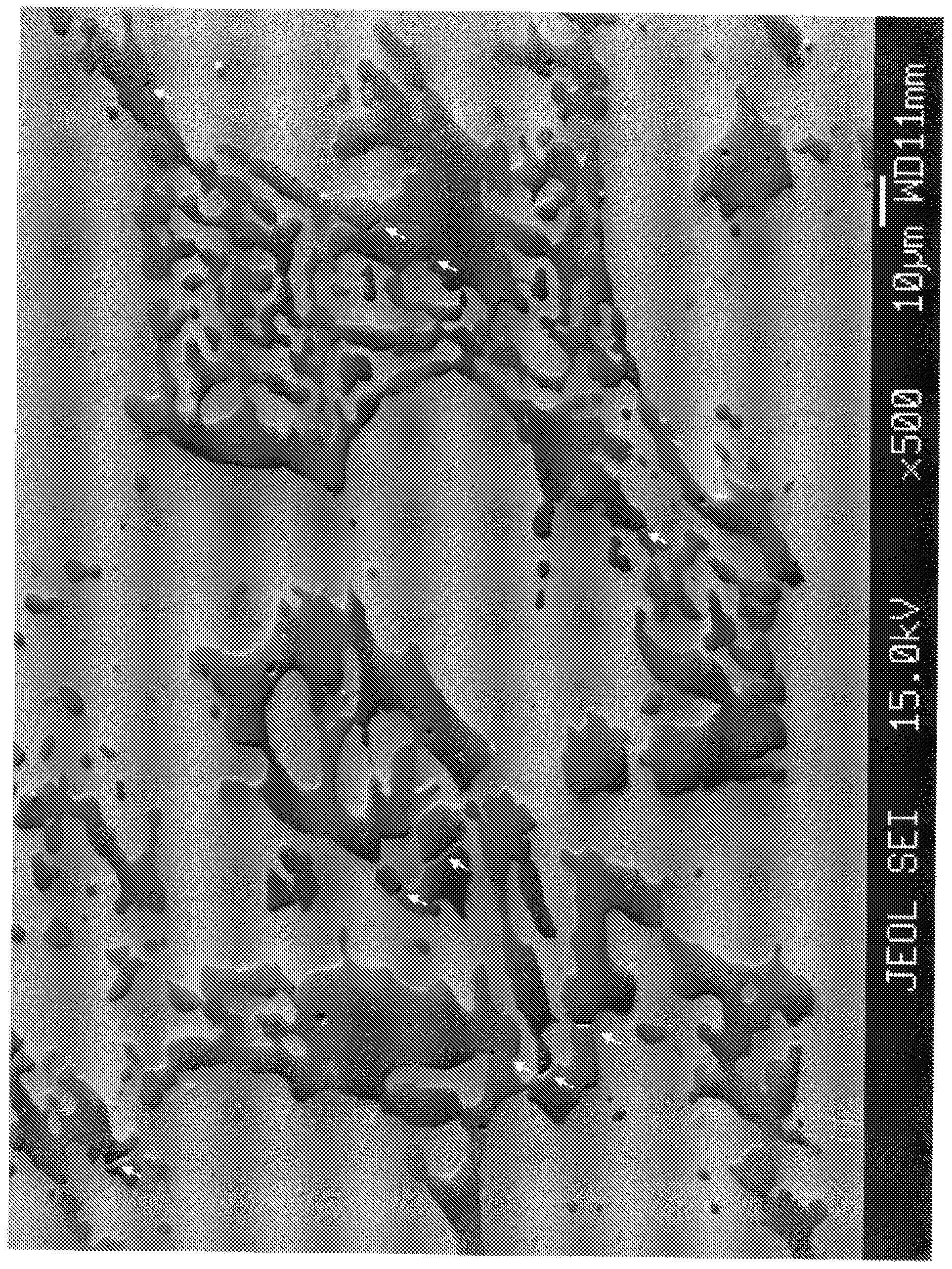

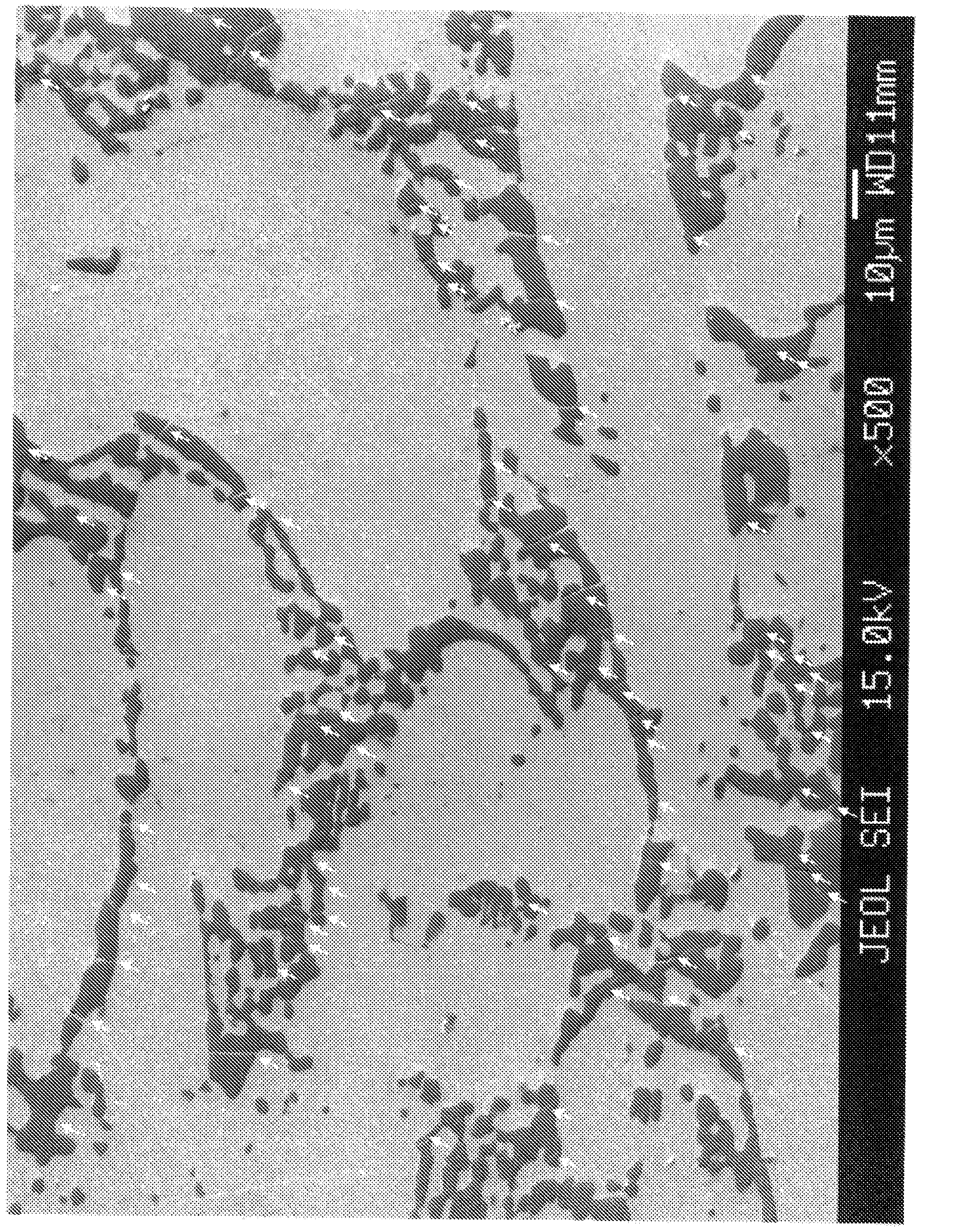

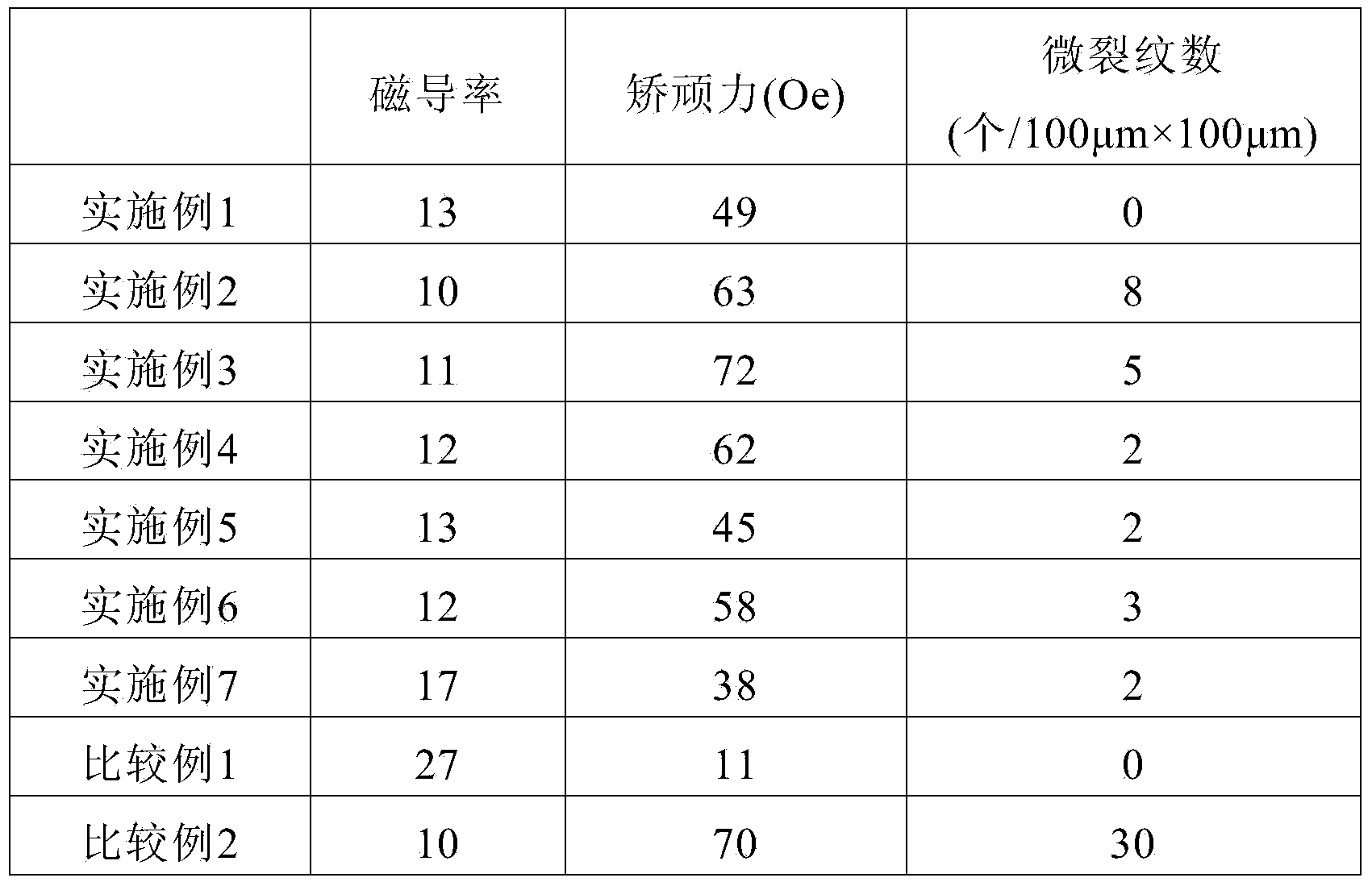

[0098] A Co-Cr-Pt-B alloy raw material consisting of Cr: 14 atomic %, Pt: 18 atomic %, B: 10 atomic %, and the remainder consisting of Co and unavoidable impurities was subjected to high-frequency (vacuum) melting. Using a mold made of cobalt, it was cast on a copper platform at a temperature from the melting point to the melting point+100° C. to obtain an ingot of 200×300×30 mmt. Next, this ingot was heated to 800° C. to 1100° C., hot-rolled repeatedly at a reduction ratio of 15% or less, then cold-rolled at an elongation rate of 1.0%, and further machined to form a target.

[0099] It should be noted that, in the above-mentioned hot rolling, specifically, it is repeated several to tens of times at a reduction ratio of 1 to 15% per pass, and the final total reduction ratio is adjusted to about 50% to about 80%. %. The following examples and comparative examples were also hot-rolled in the same manner.

[0100] Then, the maximum magnetic permeability (μmax) and the coercive ...

Embodiment 2

[0102] A Co-Cr-Pt-B alloy raw material consisting of Cr: 14 atomic %, Pt: 18 atomic %, B: 10 atomic %, and the remainder consisting of Co and unavoidable impurities was subjected to high-frequency (vacuum) melting. Using a mold made of cobalt, it was cast on a copper platform at a temperature from the melting point to the melting point+100° C. to obtain an ingot of 200×300×30 mmt. Next, this ingot was heated to 800° C. to 1100° C., hot-rolled repeatedly at a reduction ratio of 15% or less, then cold-rolled at an elongation rate of 2.0%, and further machined to form a target.

[0103] Then, the maximum magnetic permeability (μmax) and the coercive force (Hc) of the horizontal direction with respect to the sputtering surface of this target were measured using the B-H measuring instrument (BHU-6020) manufactured by Riken Electronics. In addition, the number of microcracks was measured using FE-EPMA (model number: JXA-8500F) manufactured by JEOL Corporation. As a result, the maxi...

Embodiment 3

[0105] A Co-Cr-Pt-B alloy raw material consisting of Cr: 14 atomic %, Pt: 18 atomic %, B: 10 atomic %, and the remainder consisting of Co and unavoidable impurities was subjected to high-frequency (vacuum) melting. Using a mold made of cobalt, it was cast on a copper platform at a temperature from the melting point to the melting point+100° C. to obtain an ingot of 200×300×30 mmt. Next, the ingot is heated to 800°C to 1100°C, hot-rolled repeatedly at a reduction ratio of 15% or less, heated to 900°C, and hot-rolled at a reduction ratio of 10% in one pass immediately at 20 The target is kept in water at ℃ for 30 seconds or more, water-cooled (quick cooling), and further machined (including surface grinding) to finish it into a target.

[0106] Then, the maximum magnetic permeability (μmax) and the coercive force (Hc) of the horizontal direction with respect to the sputtering surface of this target were measured using the B-H measuring instrument (BHU-6020) manufactured by Riken...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com