Start-up method of gasifier, gasification device and combined coal gasification power generation equipment

A start-up method and gasifier technology, which are applied in gasification process, mechanical equipment, steam engine devices, etc., to achieve the effect of preventing or inhibiting the production of black smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

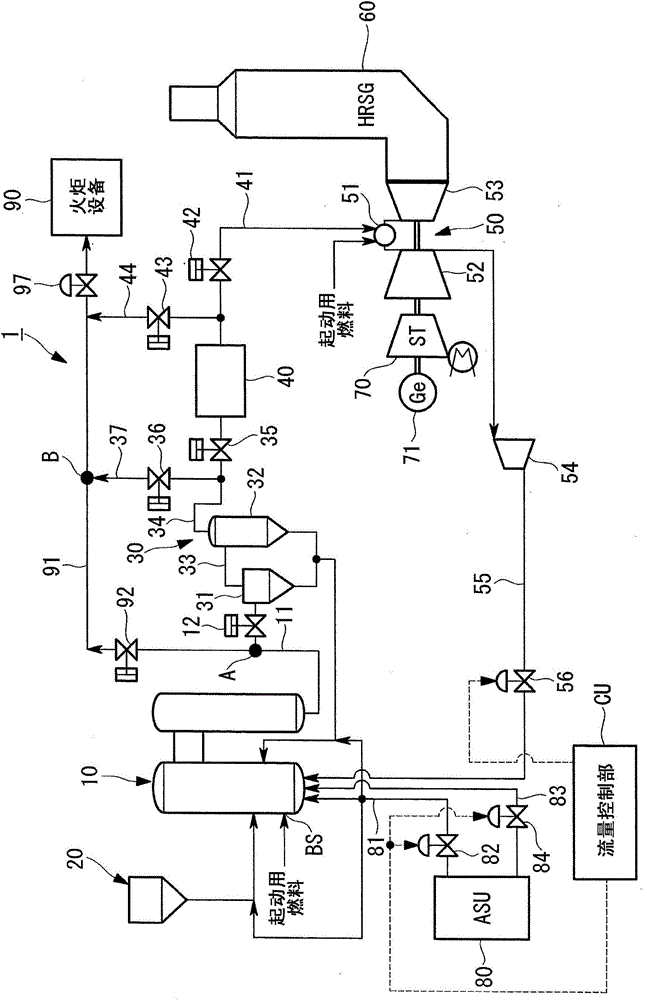

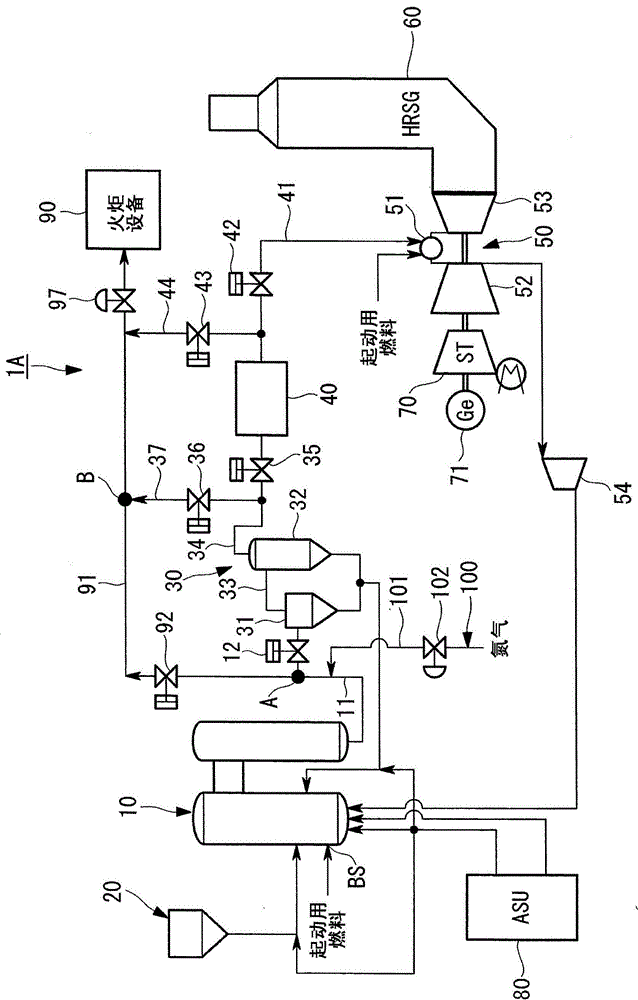

[0068] Hereinafter, one embodiment will be described with reference to the drawings regarding the start-up method of the gasifier, the gasifier, and the combined coal gasification power generation facility of the present invention.

[0069] The gasifier described below is used in e.g. figure 1 The shown integrated coal gasification power plant (hereinafter referred to as "IGCC") 1 is used as an apparatus for injecting pulverized coal (powdered coal) into a furnace to generate combustible gas (coal gas). It should be noted that, in the following description, the coal gasifier 10 that generates combustible gas from pulverized coal is exemplified, but the gasifier of the present invention can also be applied to, for example, thinning wood, waste wood, driftwood, grass, waste Gasification of other solid carbonaceous fuels such as waste, sludge, tires and other biomass fuels.

[0070] figure 1 The IGCC 1 of the first embodiment, which shows a schematic configuration example, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com