Scanner for industrial X radial negative using line array video camera

A camera and X-ray technology, applied in the field of digital devices, can solve problems such as large blackness, low contrast, and thick film base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

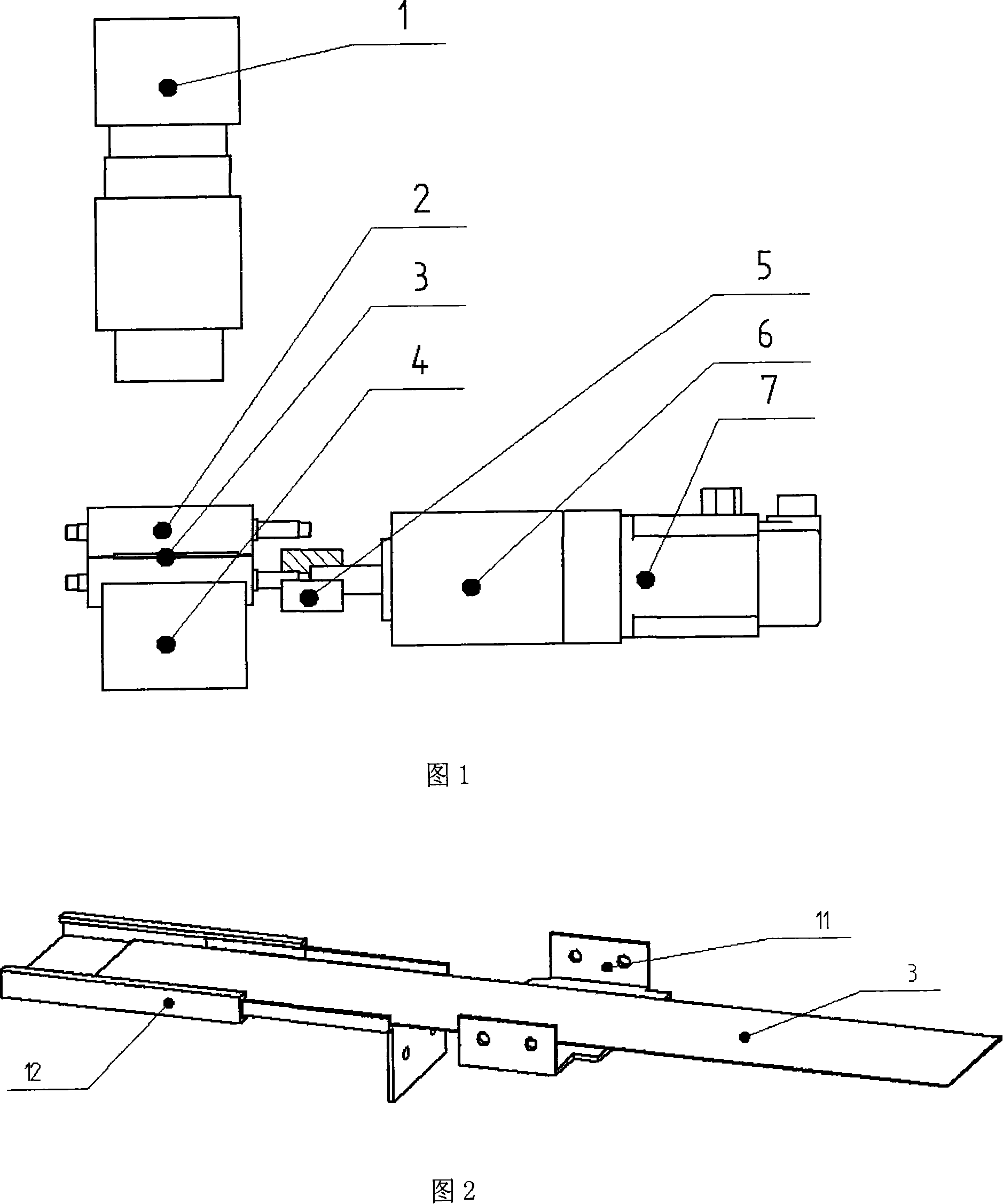

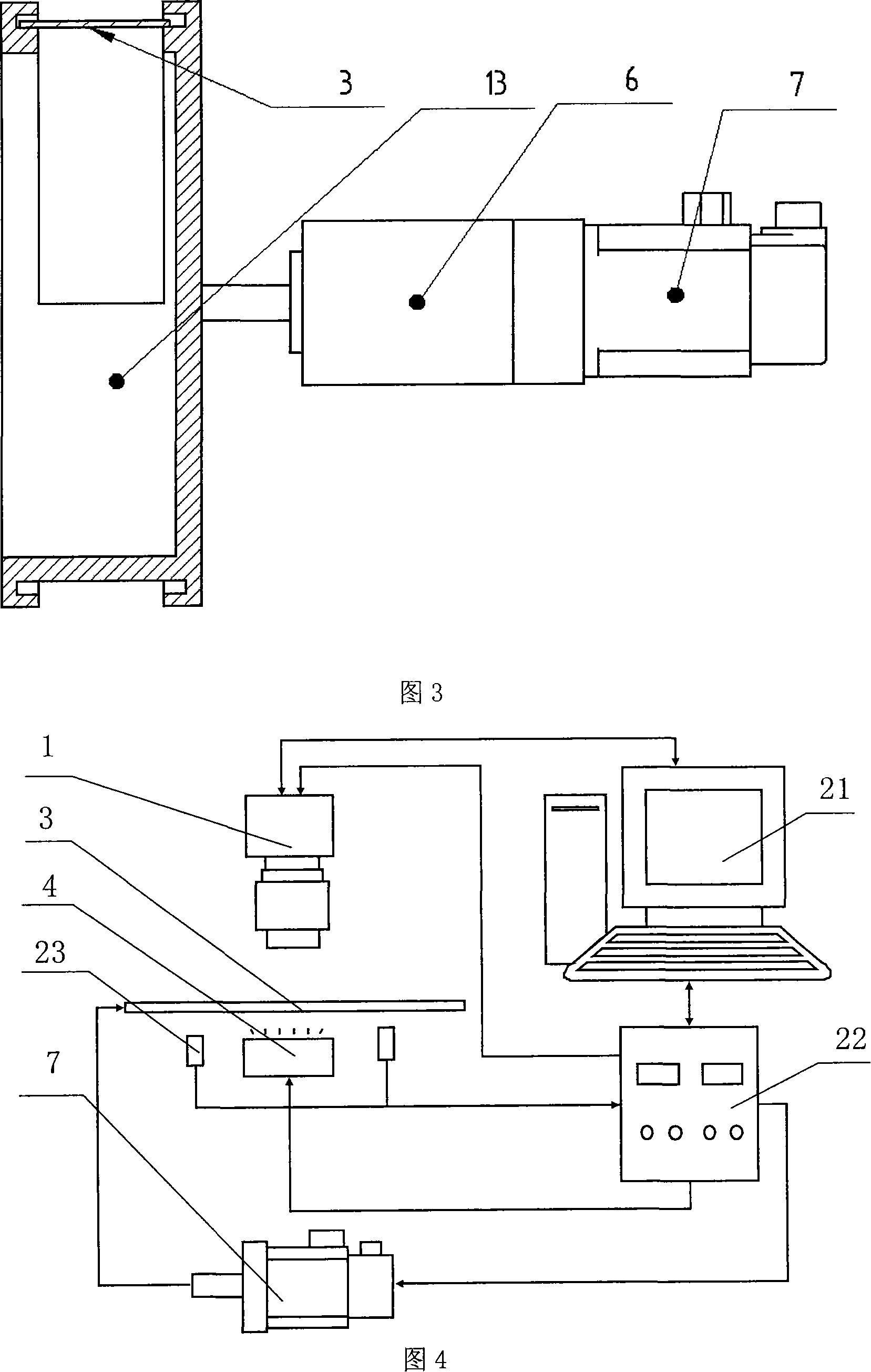

[0028] The linear array camera 1 adopts a linear array CCD, the light source 4 adopts a cold light source, the motor 7 is a servo motor with an encoder, the movement mode of the negative film 3 is translational, and the control mode of the controller 22 is set to be manual, through the controller 22 Set the translation speed of the film, the luminous intensity of the light source 4, the delay time of the delayer of the photoelectric switch 23, and the CCD adopts an external trigger mode.

[0029] The mode that the software in the computer 21 is set film acquisition is an external trigger mode, sets acquisition line number and line frequency, sets the column number of acquisition image, sets the horizontal offset and vertical offset of acquisition image, and exposure time is line time, set the CCD gain size, and select the image storage path. The above parameters have default values, and can also be set and saved according to actual needs, and called later.

[0030] The film 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com