Automatic recognition method for sintered ore essential mineral phase

An automatic identification and mineral phase technology, applied in character and pattern recognition, measuring devices, material analysis through optical means, etc., can solve the problems of low accuracy of statistical methods, easy misidentification, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] A method for automatic identification of main mineral phases of sintered ore, the steps of which are:

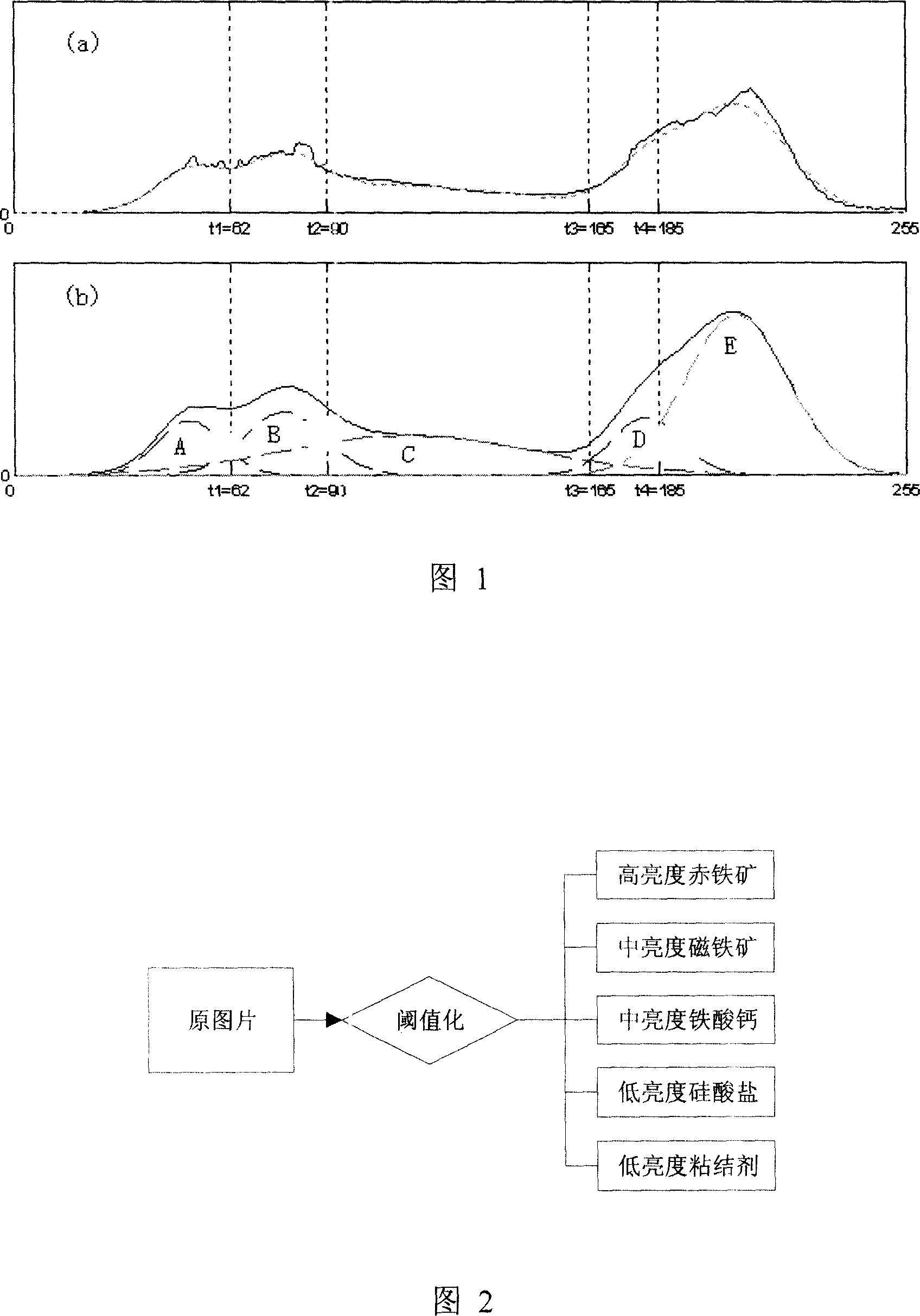

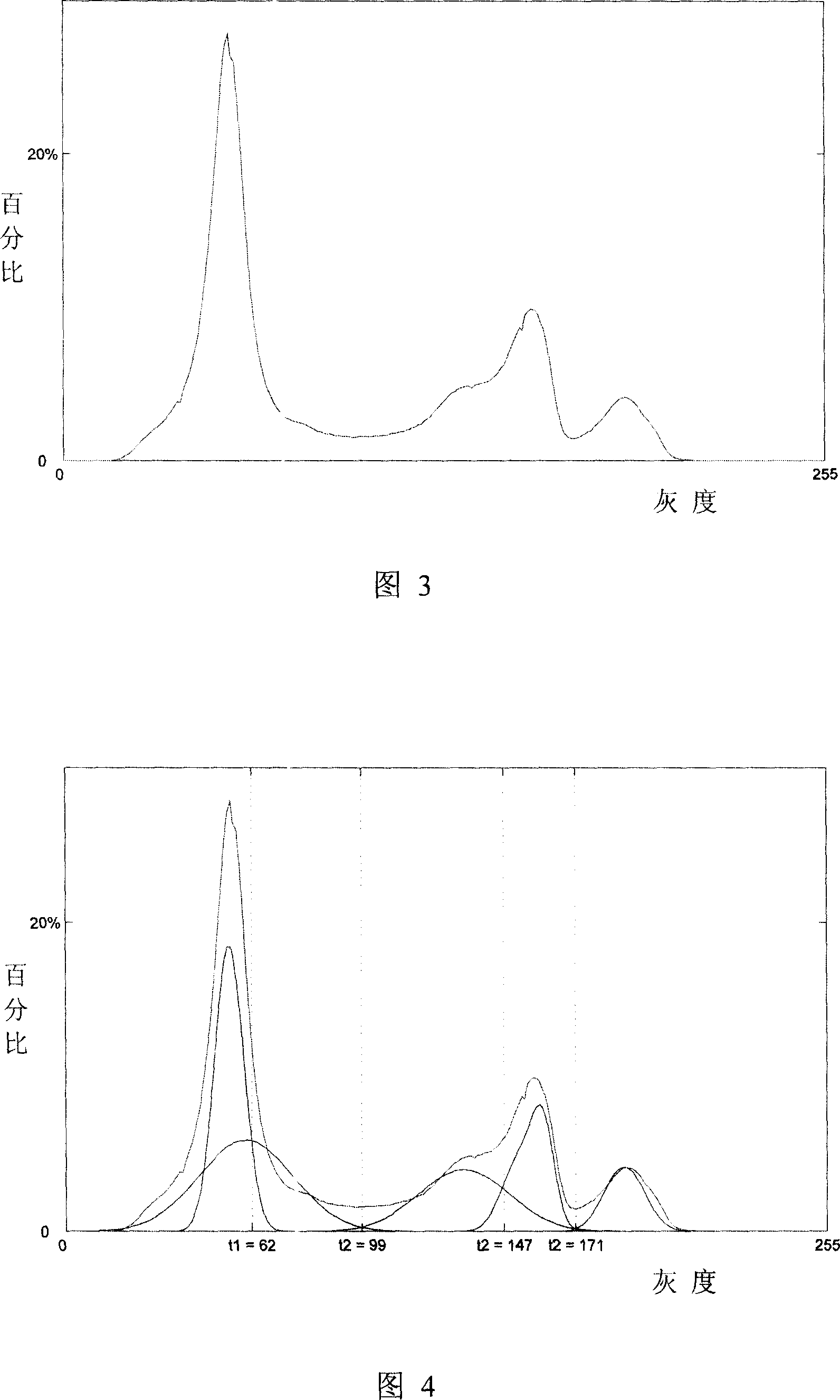

[0078] 1. Sampling and analyzing the iron ore numbered 3DL0603, collecting a total of 400 pictures with a size of 800×800 pixels. First, the statistics of red, green, and blue channels and the grayscale histogram after grayscale conversion are carried out for each image; Green, blue and gray total histogram distribution; see Figure 3, Figure 3 is the original red total histogram distribution.

[0079] 2. Use the EM algorithm to perform histogram approximation to obtain four optimal thresholds, t1=62, t2=99, t3=145, t4=171, see FIG. 4 . Take M=5, the iteration error is 10 -3 , using the EM algorithm can achieve stability after an average of 200 iterations.

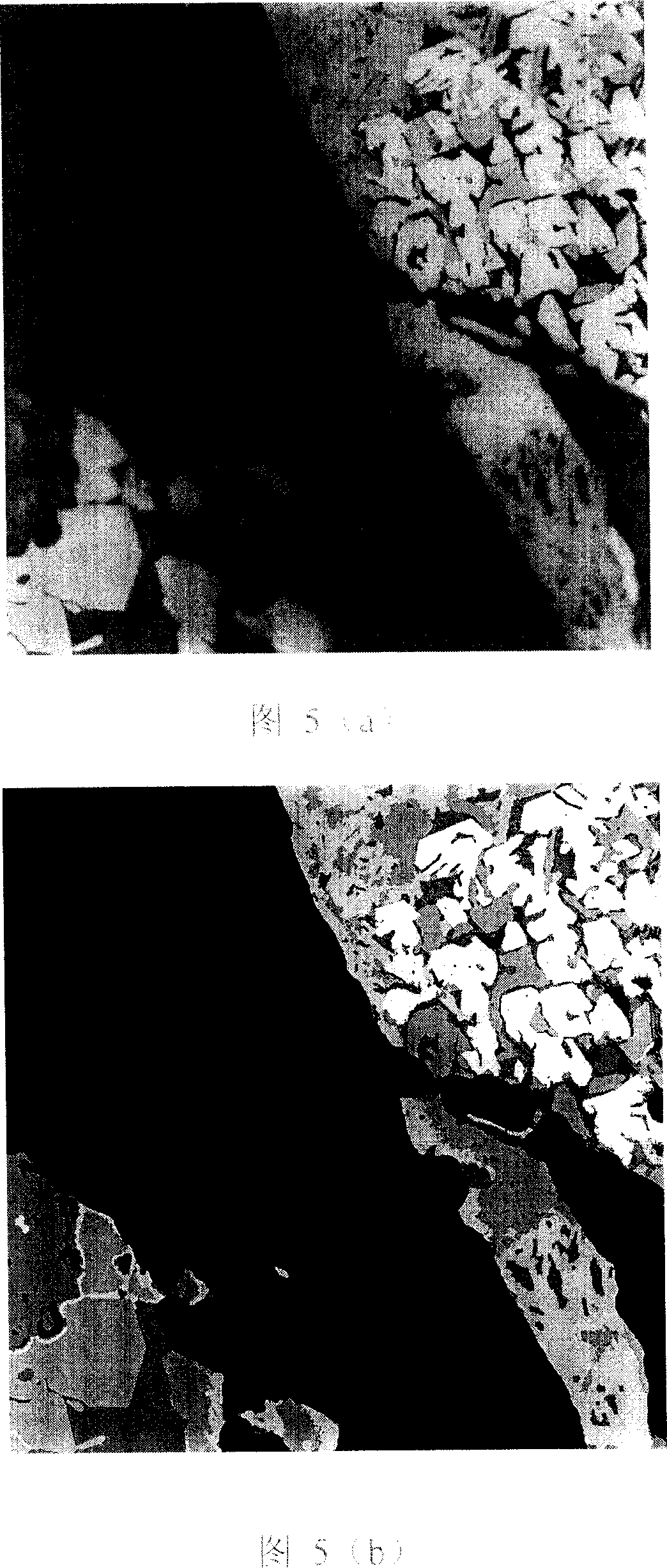

[0080] 3. After obtaining the optimal threshold, return to the first image to start the analysis and statistics process, and divide the image into component regions according to the threshold. See Fig. 5(a) for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com