Pre-rolling steel strip surface cleaning device

A surface cleaning and front belt technology, which is applied to workpiece surface treatment equipment, metal rolling, metal rolling, etc., can solve the problems of foreign matter contamination, foreign matter pressing defects on the surface of steel plates, etc., to improve scrubbing ability and reduce chloride ions. the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

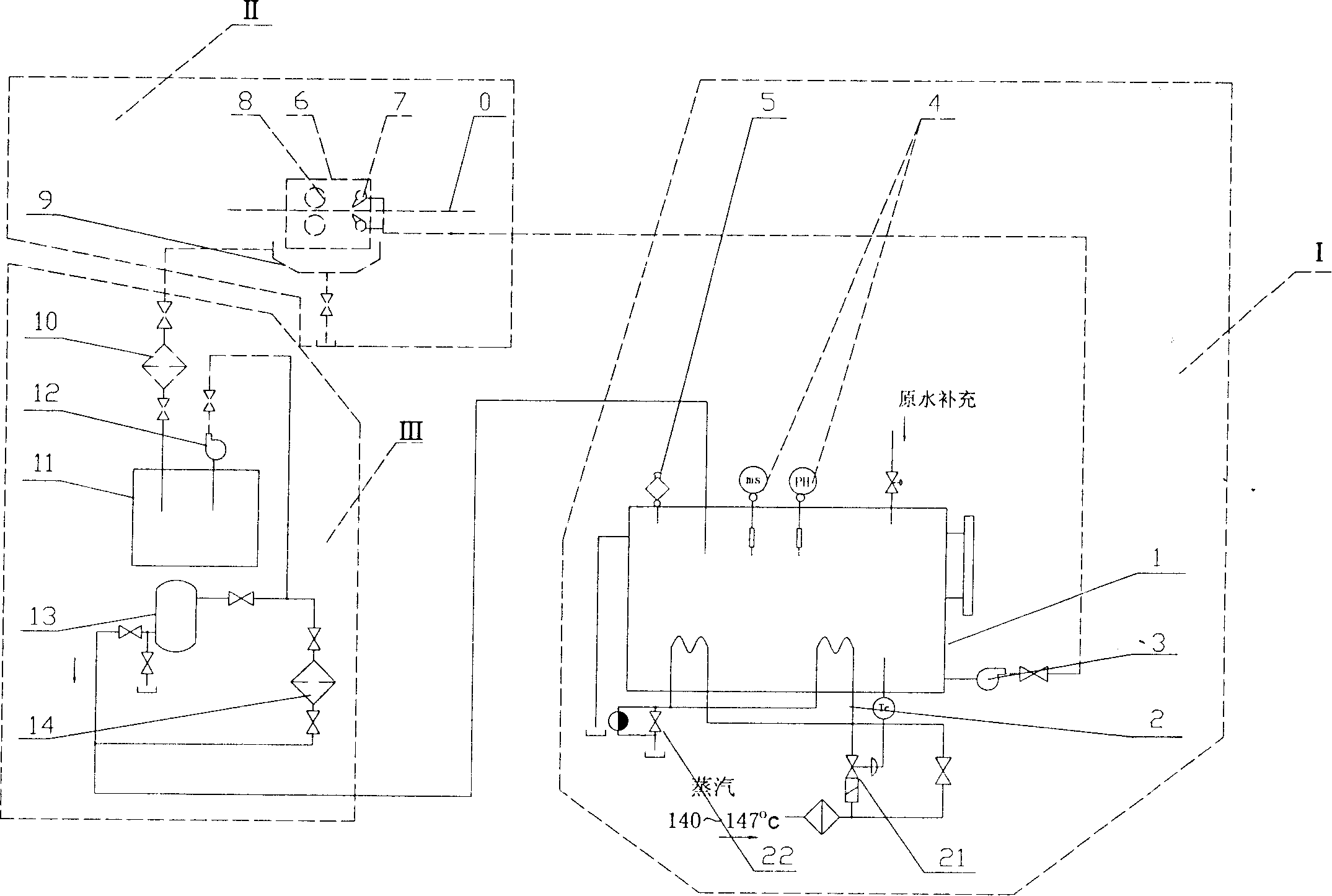

[0014] As mentioned above, the foreign matter on the surface of the steel strip mainly comes from two aspects. The foreign matter produced in these two aspects is relatively loose on the surface of the steel plate. As shown in Figure 1, in order to ensure the cleaning effect, this embodiment mainly adopts the following Aspects of measures:

[0015] 1) A group of brush rollers 8 are installed in the cleaning part II, which are respectively arranged on the upper and lower surfaces of the steel strip, and their rotation direction is opposite to that of the strip steel, thus ensuring the scrubbing effect of the brush rollers 8 on the strip steel;

[0016] 2) Pure water is used as the cleaning medium of the steel strip, and the pure water is sprayed onto the surface of the steel strip at a speed of 2 to 10 m / s and at an angle of 10° to 50° with the strip;

[0017] 3) In order to reduce the amount of cleaning medium, pure water for cleaning is recycled, and only a small amount of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com