Cover tape for packaging electronic parts and method for preparing the cover tape

A technology for packaging electronics and components, applied in electrical components, electrical components, etc., can solve the problems of uneven peel strength, no conventional cover tape, high cost, etc., and achieve the effect of excellent work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

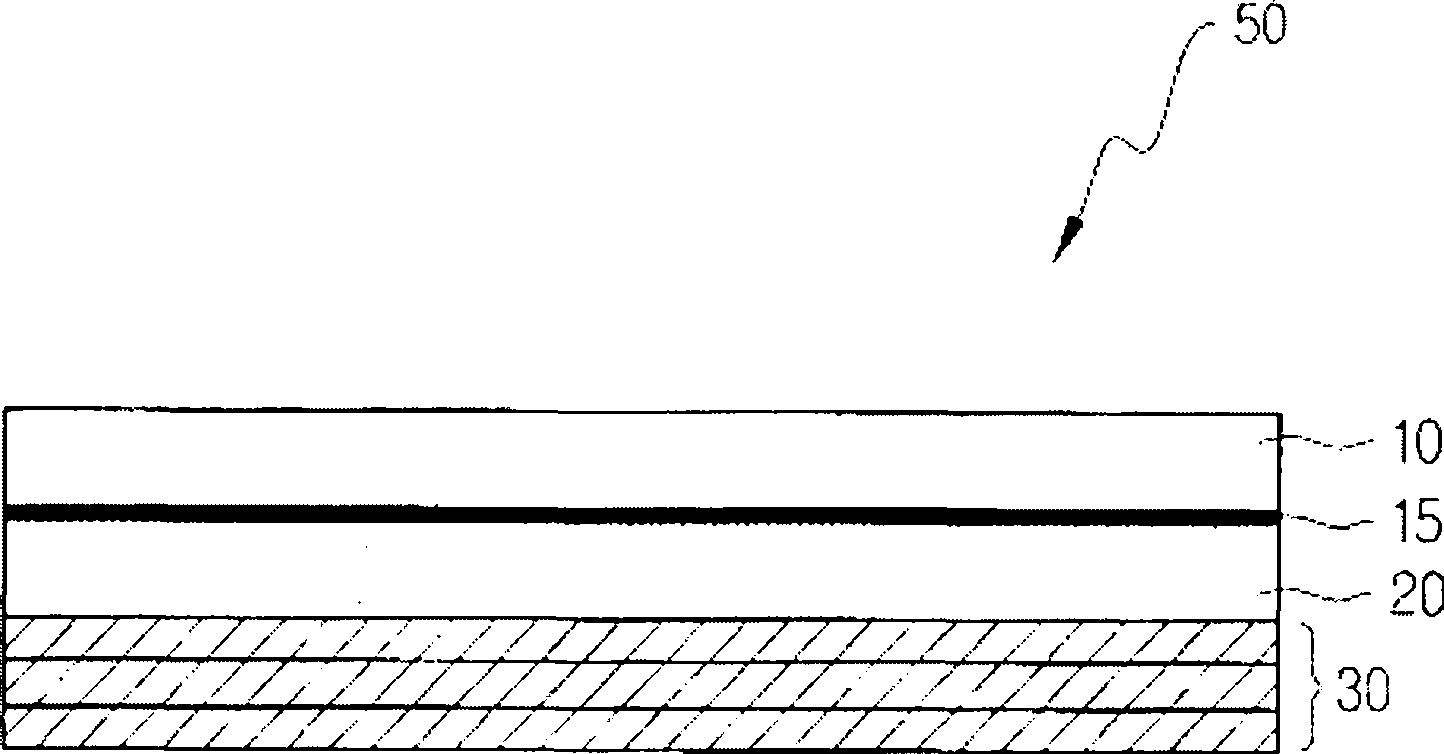

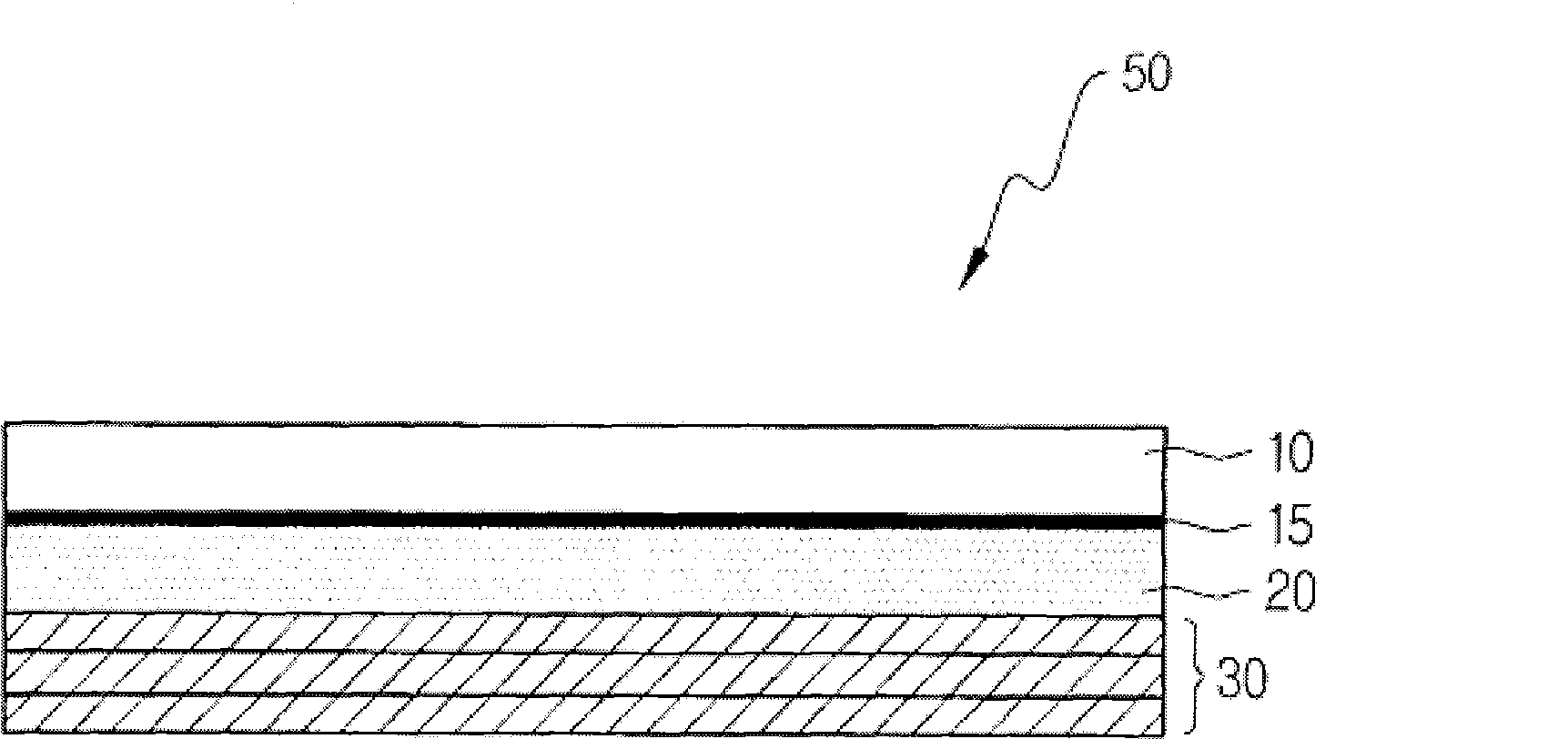

[0073] A heat sealant using SEBS dissolved in toluene solvent was gravure-coated onto a cover tape (PET film + acrylic adhesive (Product 9600 by Sungdo Chemical, Co., Ltd) + LLDPE film) 3 times, wherein the coating thickness The first time is 5 μm, the second time is 5 μm, and the third time is 5 μm.

Embodiment 2

[0075] Gravure coating was performed three times in the same manner as in Example 1, wherein the coating thickness was 4 μm for the first time, 3 μm for the second time, and 3 μm for the third time.

Embodiment 3

[0077] Gravure coating was performed twice in the same manner as in Example 1, wherein the coating thickness was 5 μm for the first time and 5 μm for the second time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com