Multi-position continuous lamp head and filament component production device

A production device and multi-station technology, applied in the direction of electrical components, lead-in wires, luminous bodies, etc., can solve the problems of complex process and low efficiency, and achieve the effect of high production efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

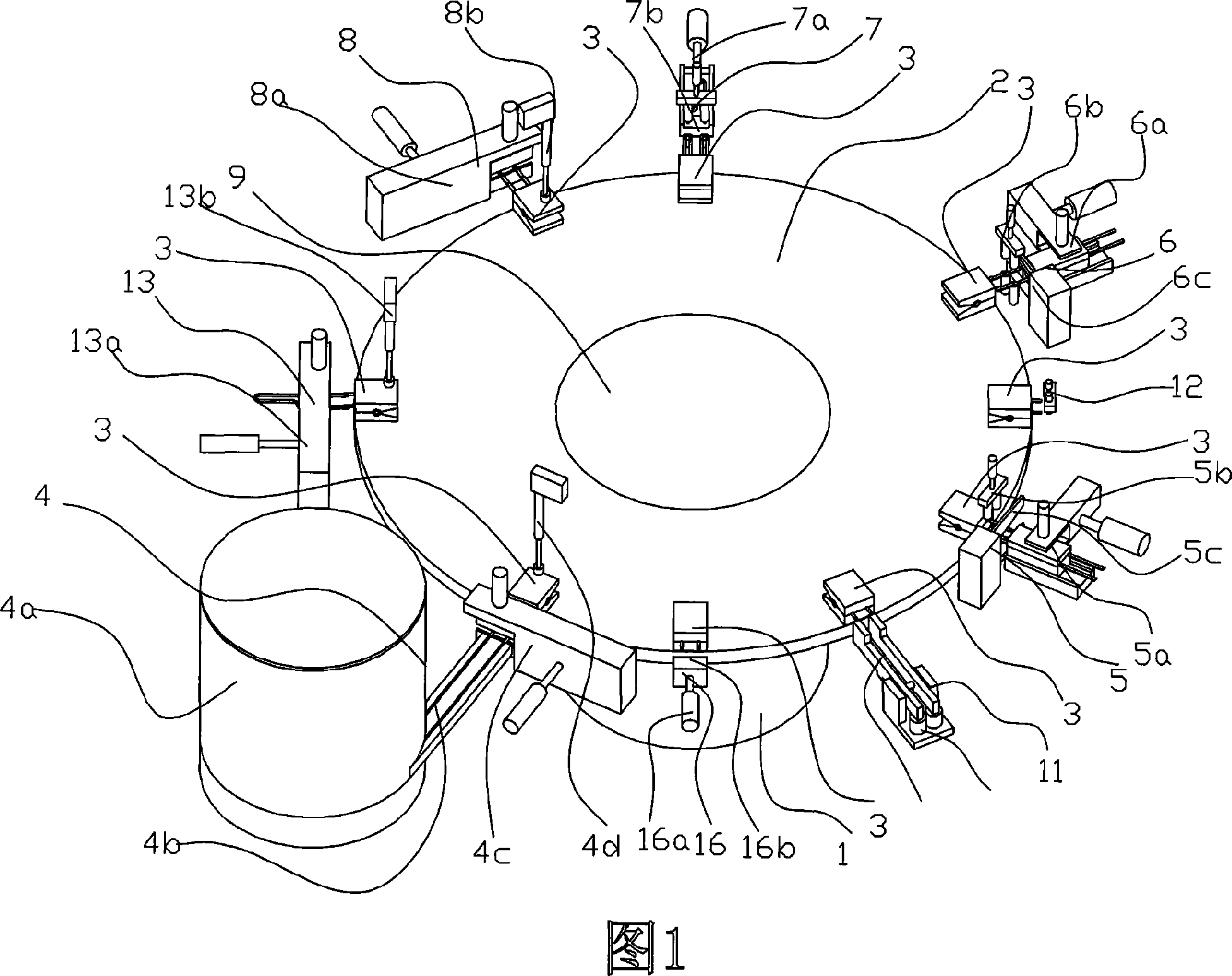

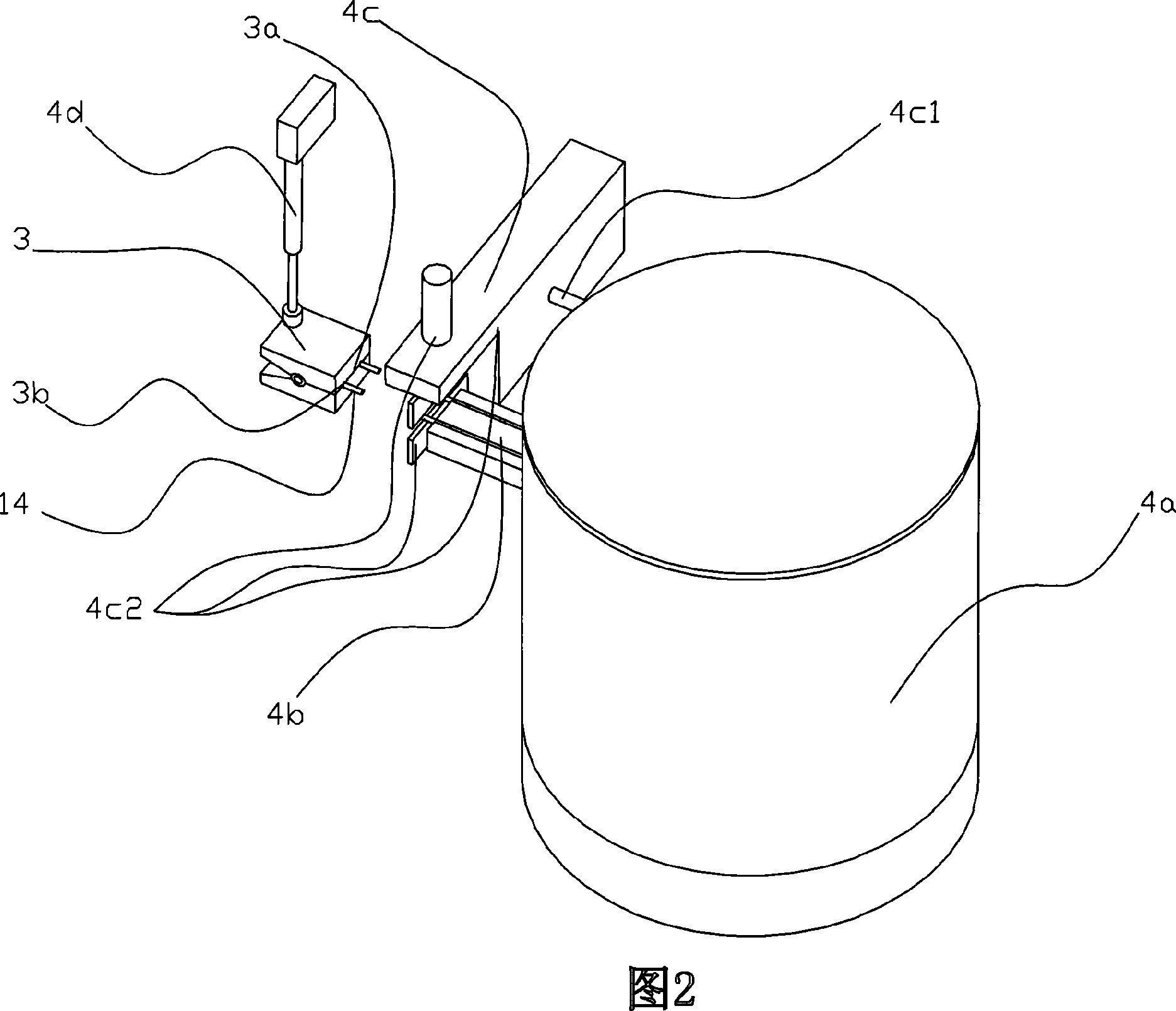

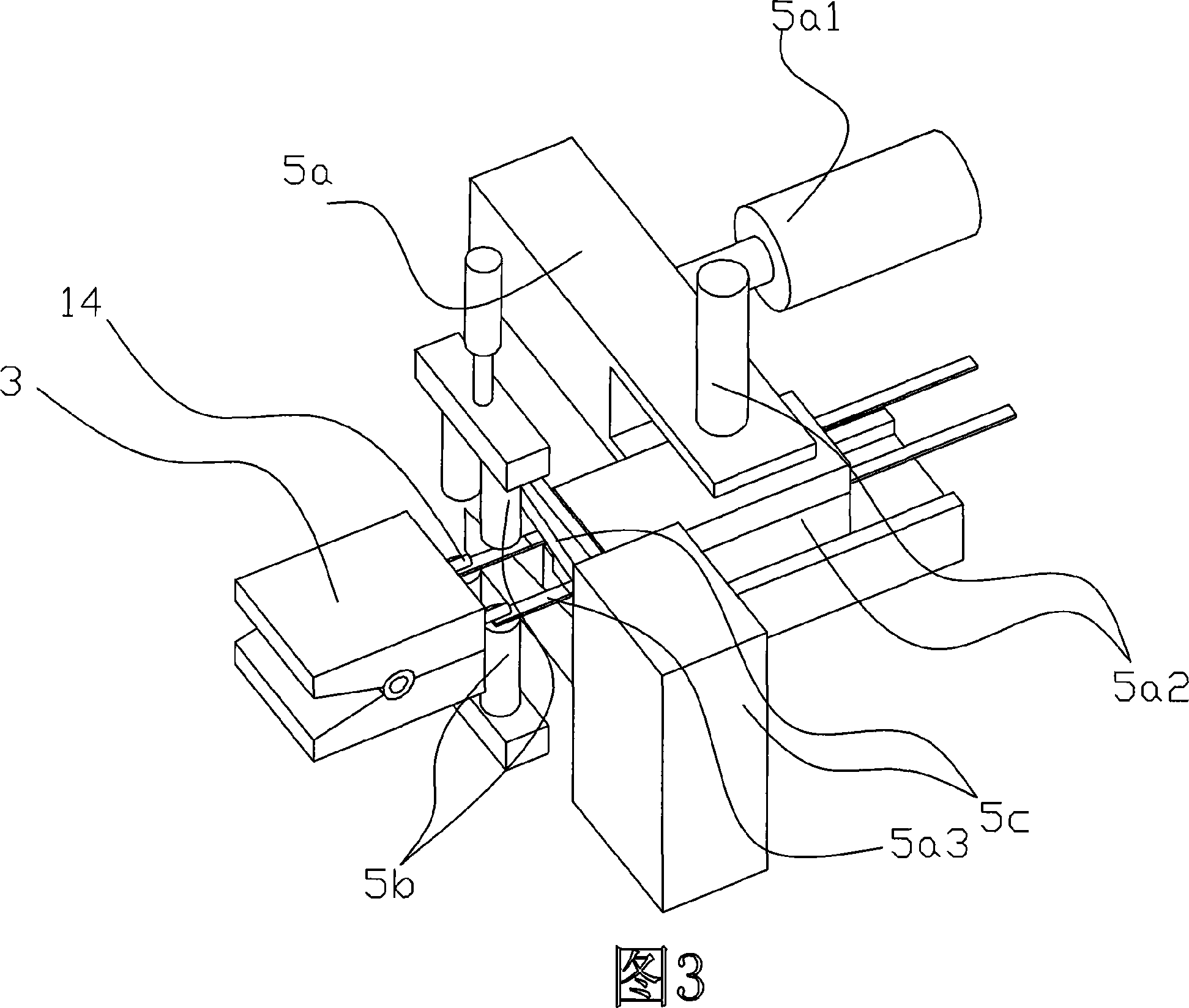

[0018] As shown in Figure 1, the present invention consists of a frame 1, a turntable 2 arranged on the frame 1, a filament foot clip 3 arranged on the turntable 2, a filament foot clamping mechanism 4 distributed next to the turntable 2, molybdenum Sheet welding mechanism 5, tantalum sheet welding mechanism 6, filament welding mechanism 7, filament member unloading mechanism 8, power transmission device 9 that drives turntable 2 to rotate, and electronic control device 10. Parallel filament foot clamping grooves 3b, the filament foot clamping mechanism 4 consists of a filament foot vibration barrel 4a, a pair of filament foot guide grooves 4b connected to the filament foot vibration barrel 4a and corresponding to the two parallel filament foot clamp grooves 3b 1. The filament foot clamping and feeding mechanism 4c is composed of a clamp pressing mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com