Embossed wheel

A technology of embossing wheel and embossing roller, applied in the field of embossing wheel, can solve the problems of high cost, complicated manufacturing process, inconvenient production plant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

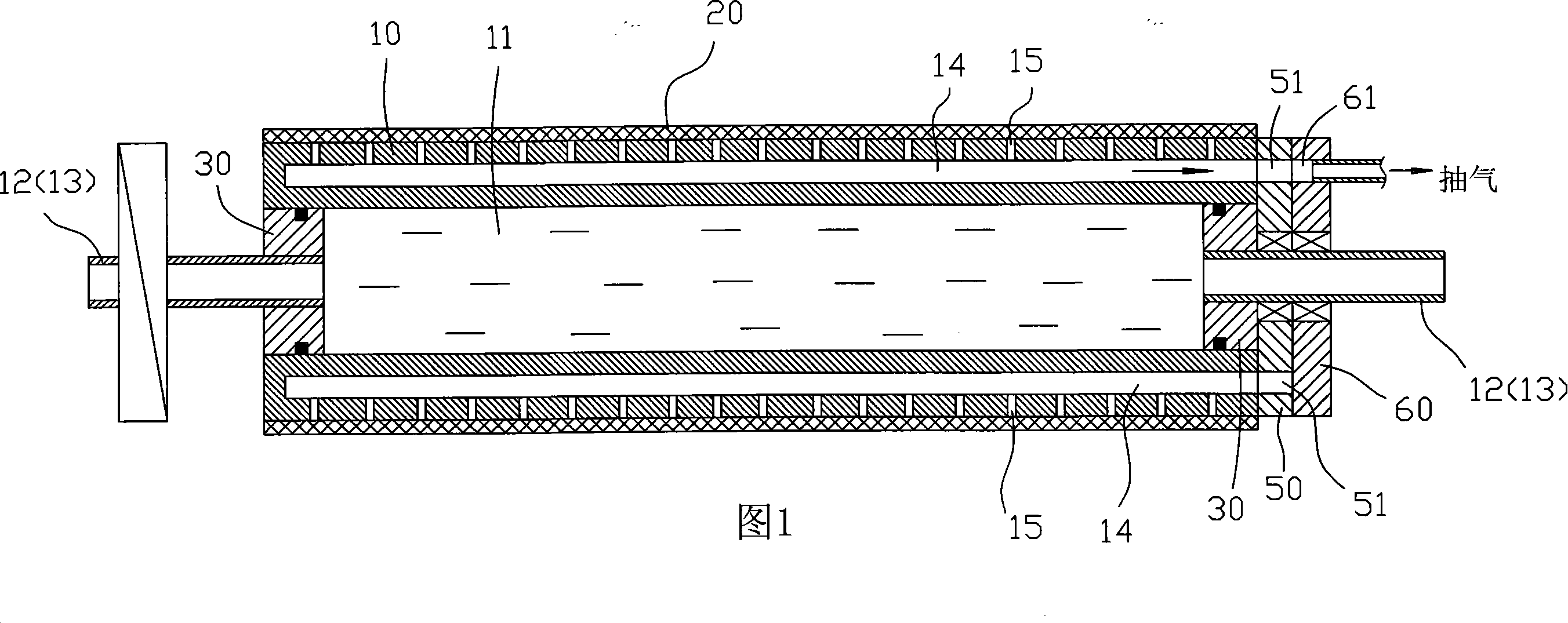

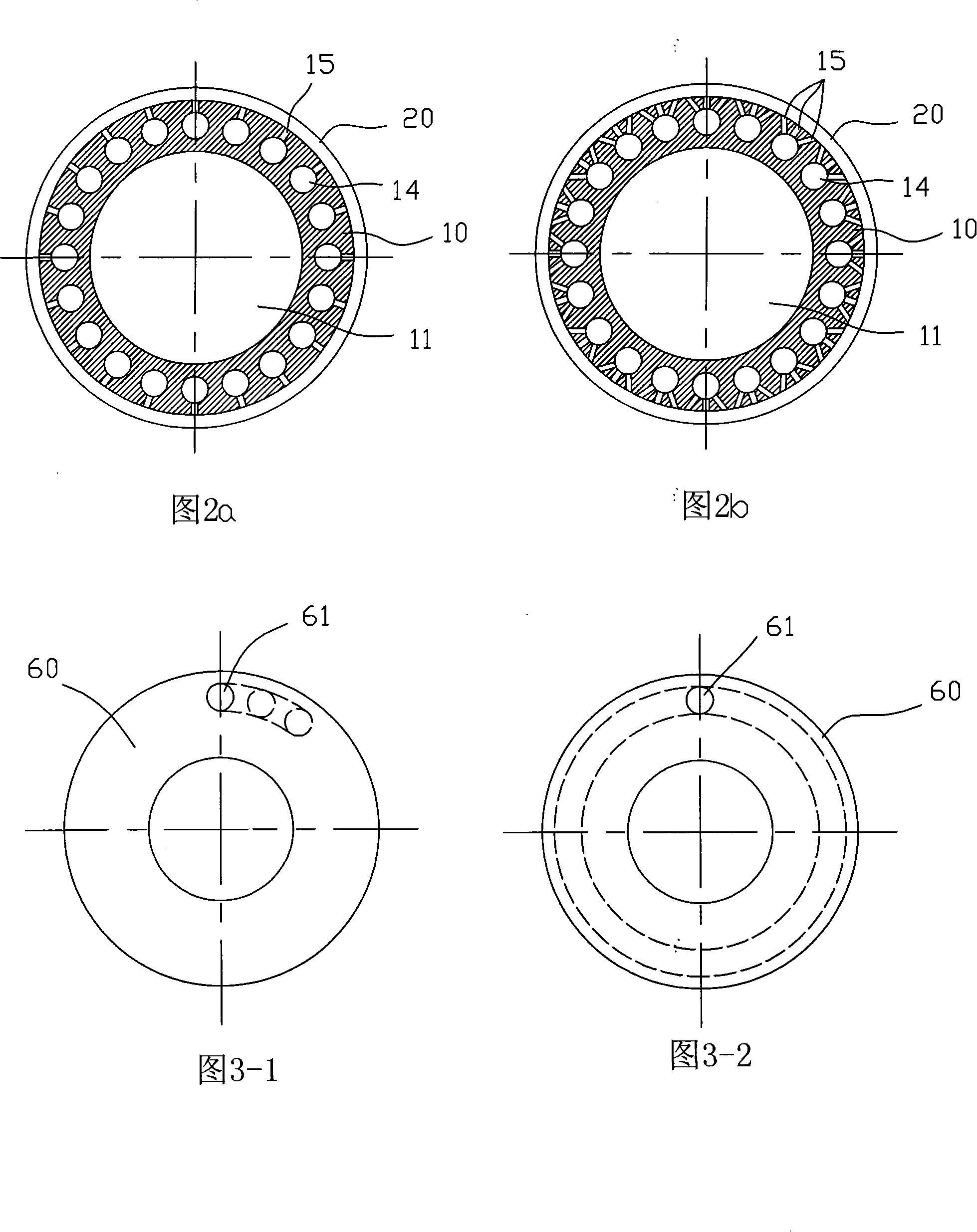

[0015] See shown in accompanying drawing 1, the present invention is the embossing wheel that is used for surface embossing molding such as artificial leather, plastic products, mainly comprises metal roll 10 and the embossing roll 20 that is coated on metal roll 10 periphery, and embossing roll 20 It is breathable, and the surface of the embossing roller 20 has a predetermined pattern. The metal roller 10 is constructed by a hollow tube, and the metal roller 10 plays a role of supporting the embossing roller 20, and rotates embossing along with the embossing roller 20. The inner cavity of the metal roller 10 forms a cooling chamber 11, and the cooling chamber 11 is connected with a water inlet pipe 12 and an outlet pipe 13; several axial holes 14 are configured on the pipe wall of the cooling chamber 11 periphery, and each axial hole 14 is There are radial air holes 15 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com