Cracking-off machine fire ring device

The technology of fire ring and fire ring body is applied in the field of glassware blasting machine, which can solve the problems of large cup height error, complex transmission structure, affecting product quality, etc., and achieve the effect of stable product quality and simple transmission system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

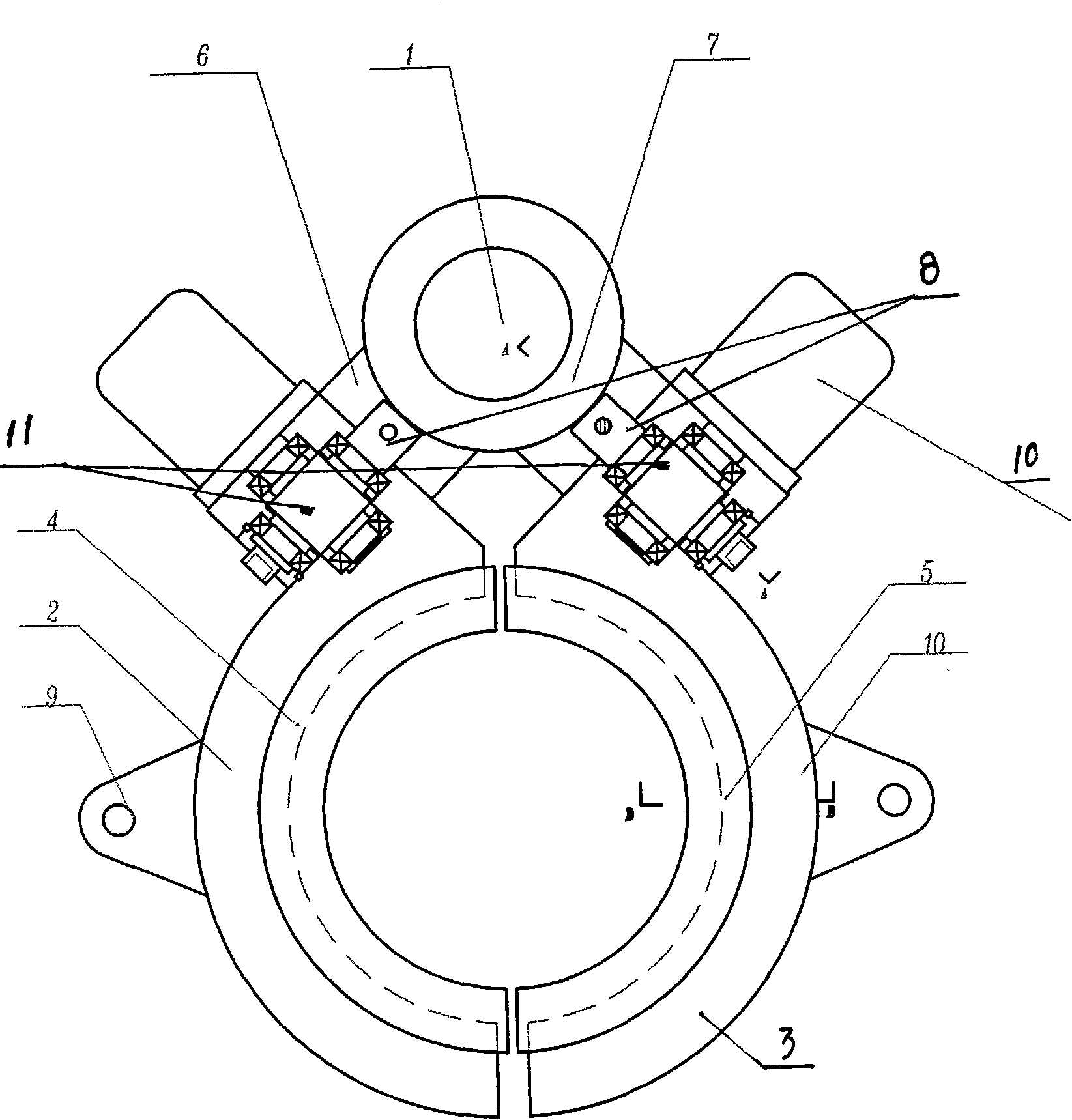

[0008] The specific embodiment: among Fig. 1, fire ring is made up of left fire ring (4) and right fire ring (5) two parts, is respectively fixed on left (2), on the right ring body (3), left (2) , the right ring body (3) are respectively fixed on the left (6) and right ring body seats (7) by pin shafts (8), and the left (6) and right ring body seats (7) have two lugs (9) respectively. ), drive the left (6), right ring body seat (7) to rotate around the vertical shaft (1), and realize the splitting and closing of the fire ring. A helical gear (11) is fastened on the pin shaft (8) connected with the right fire ring (5), and the pin shaft (8) is fastened on the left (2) and right fire ring body (3). There is a motor (13), which is connected with the helical gear (11), and the pin shaft (8) is respectively fixed with the left (2) and right fire ring body (3), and can rotate around the holes of the left (6) and right ring body seat (7) , when the motor rotation drives the helical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com