Ring shaped inner sliding track and sliding block wind-driven engine with steadying line

A technology of stabilizing cables and circular rings, which is applied in the direction of wind power engines, engines, machines/engines, etc., and can solve problems such as difficult production, high price, and heavy weight of wind blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

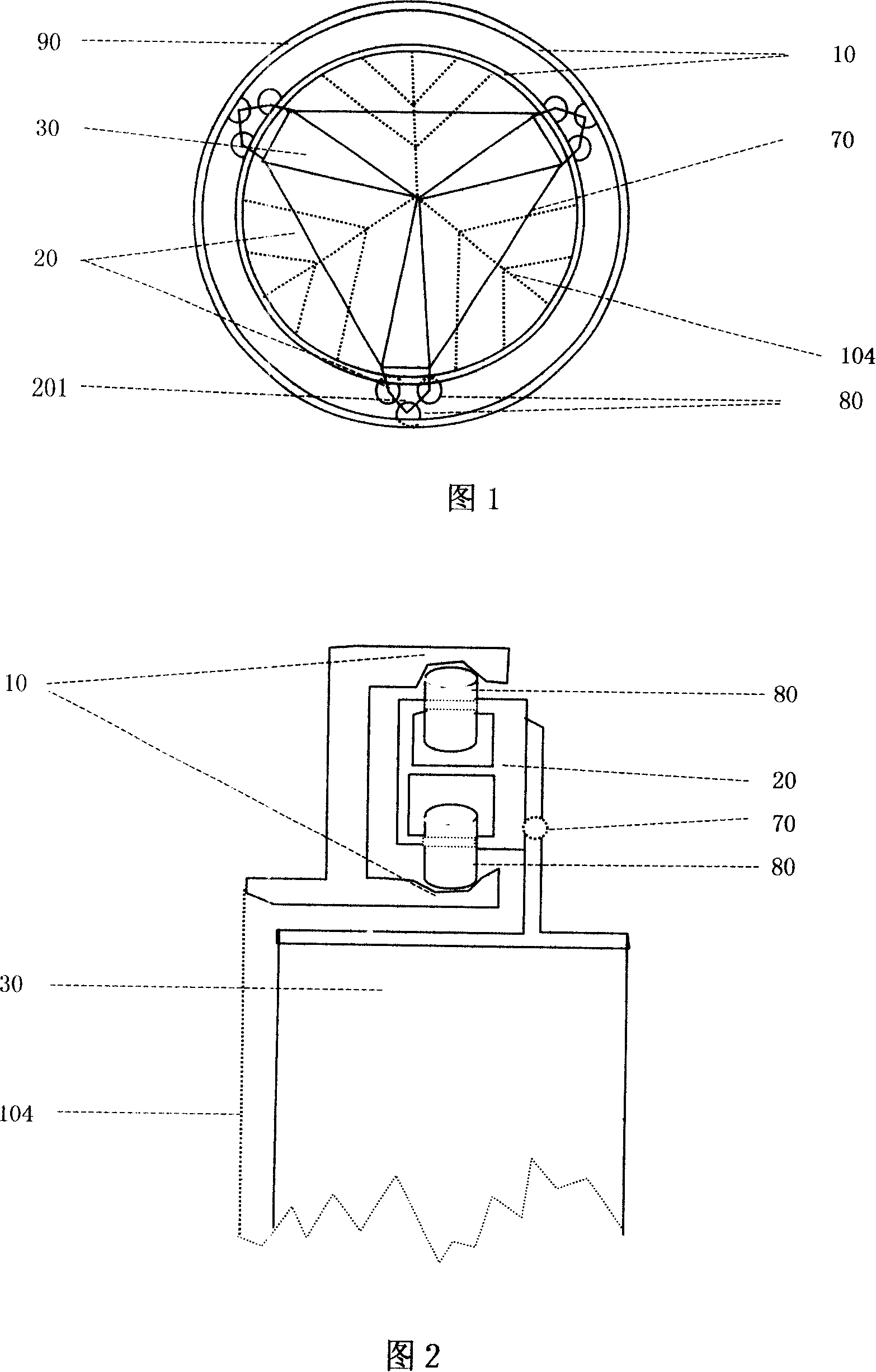

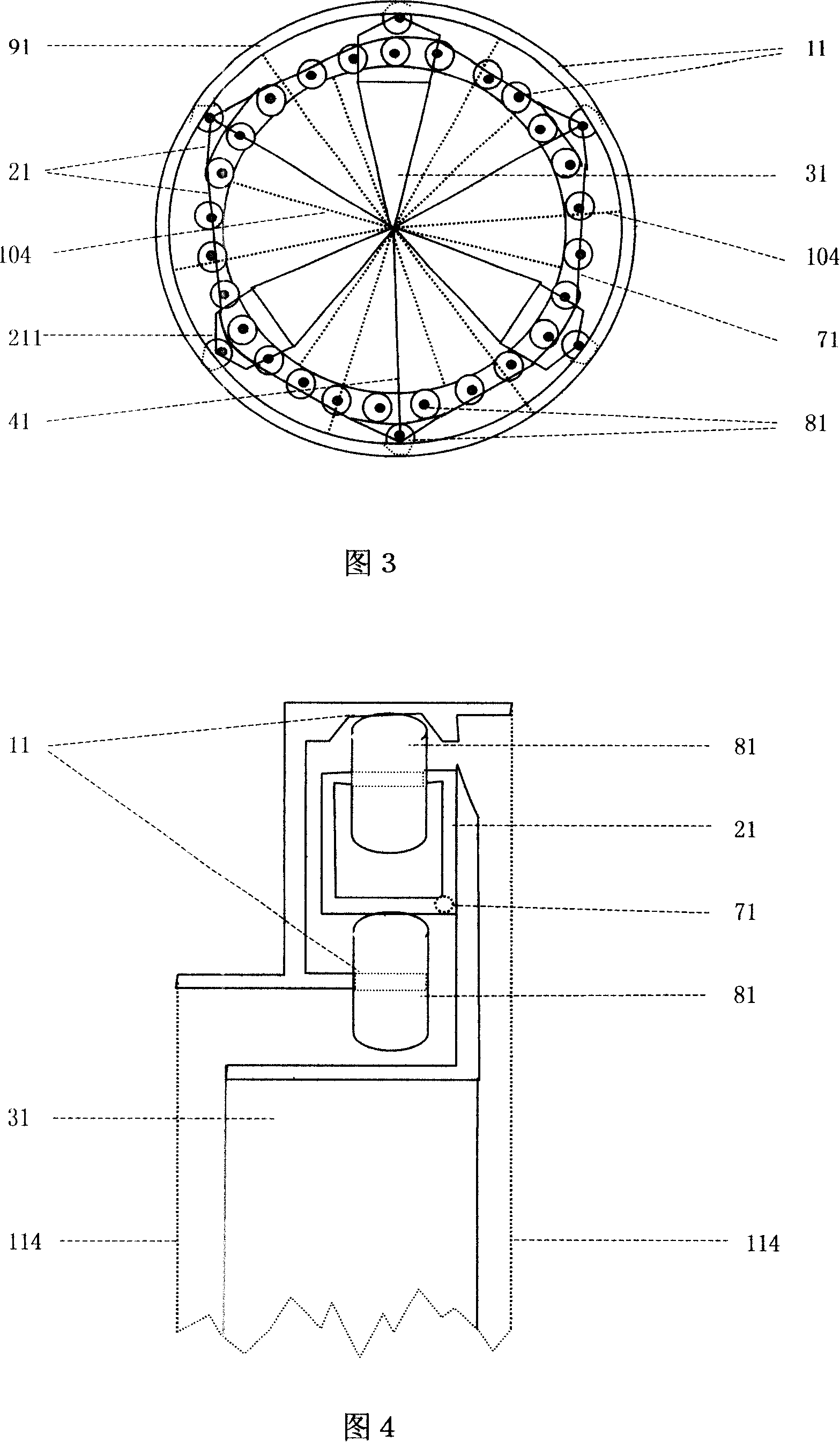

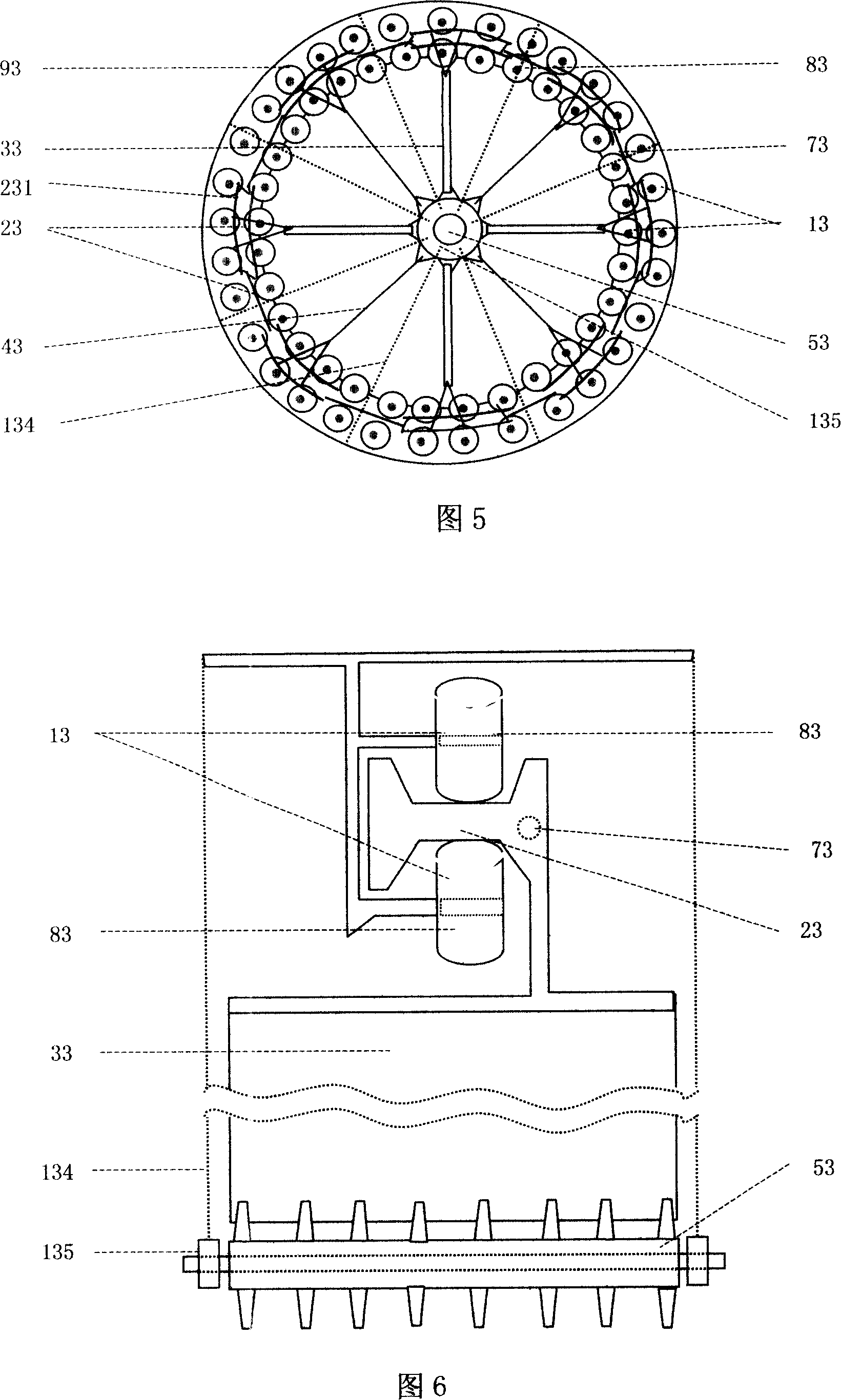

[0096] In this specification, the so-called "circular inner slide rail with stabilizing cable" is composed of two parallel circular rings, and the stabilizing cable can be fixed on the two circular rings, or on one of the circular rings . The stabilizing cable can also be fixed on the support frame or the support ring that directly provides support for the two rings, and provides tension for the two rings by being connected with the support frame or the support ring. The stabilizing cable can be arranged on one side of the annular inner slide rail, or can be arranged on both sides of the annular inner slide rail simultaneously. Except that the planes determined by the two rings forming the circular inner slide rail should be parallel, the distance between any point on the sides of each ring and the sides of other rings is constant. One ring provides support and slideway for the outside of the slider with the inside, and the other ring provides support and slideway for the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com