Back light source and its light emitting diode module group

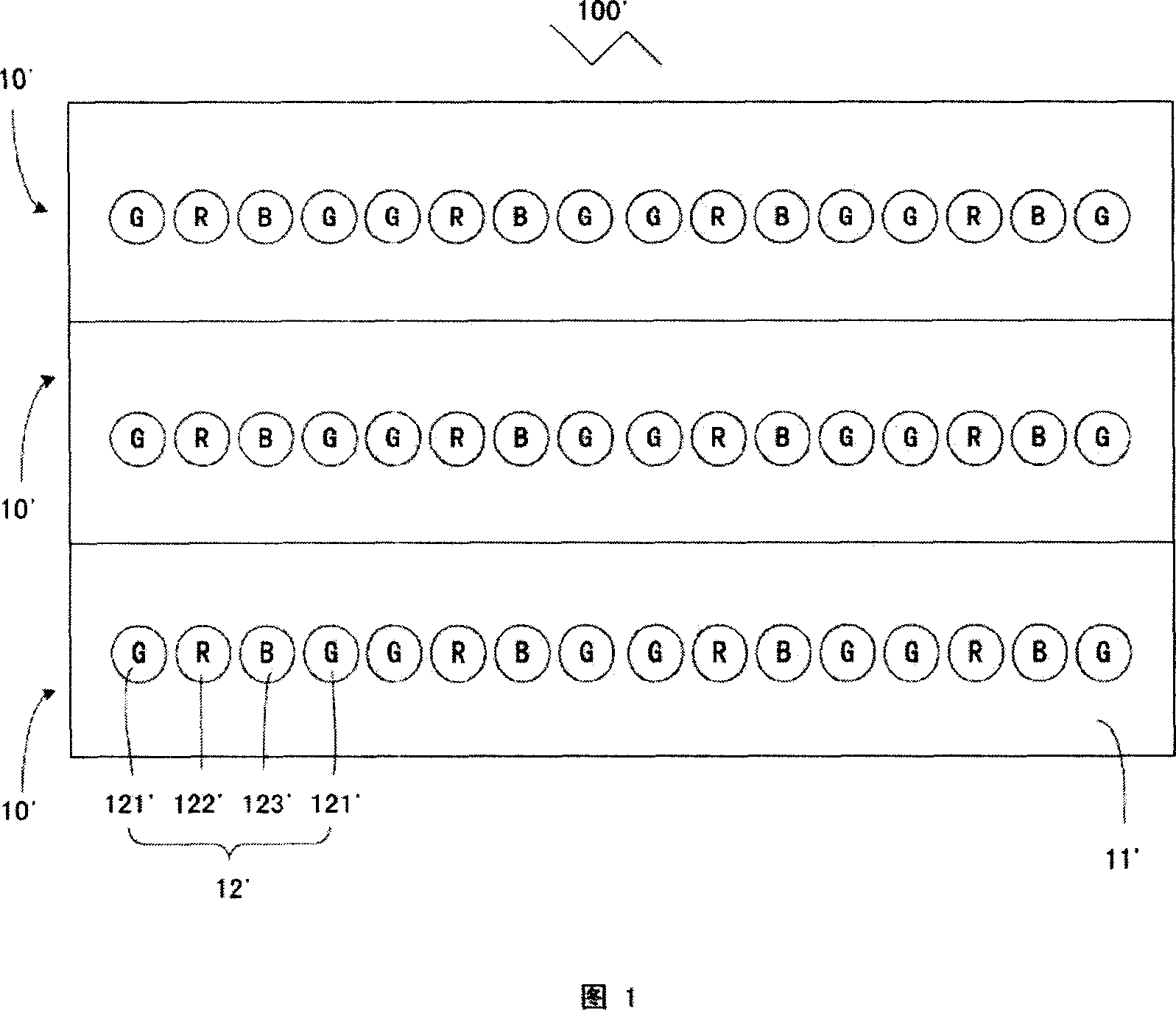

A technology of light-emitting diodes and backlights, which is applied to light sources, semiconductor devices of light-emitting elements, optics, etc., can solve the problems of overheating of the module 10' and the difficulty of dissipating heat in a concentrated local area, and achieves easy heat dissipation and avoids local overheating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

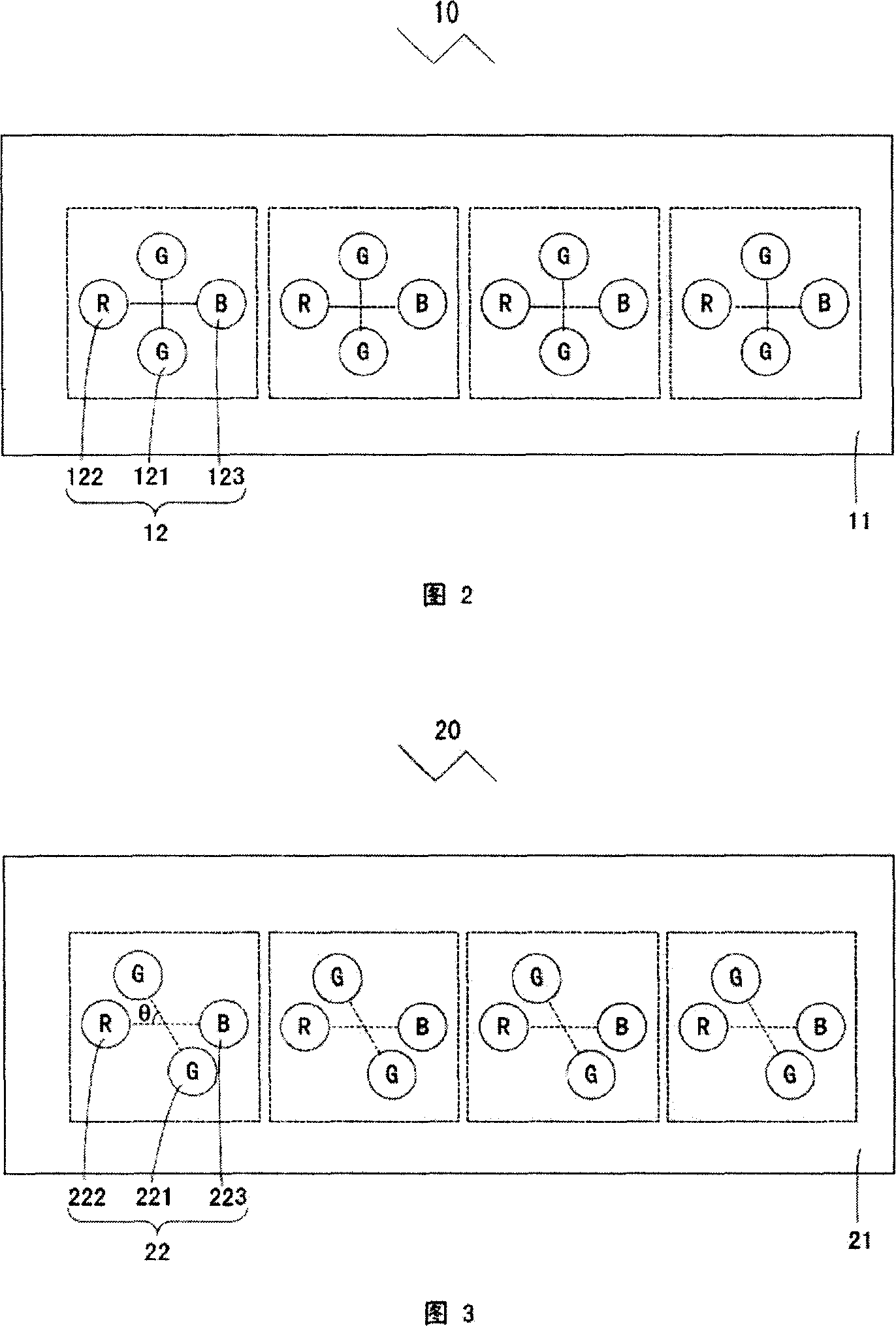

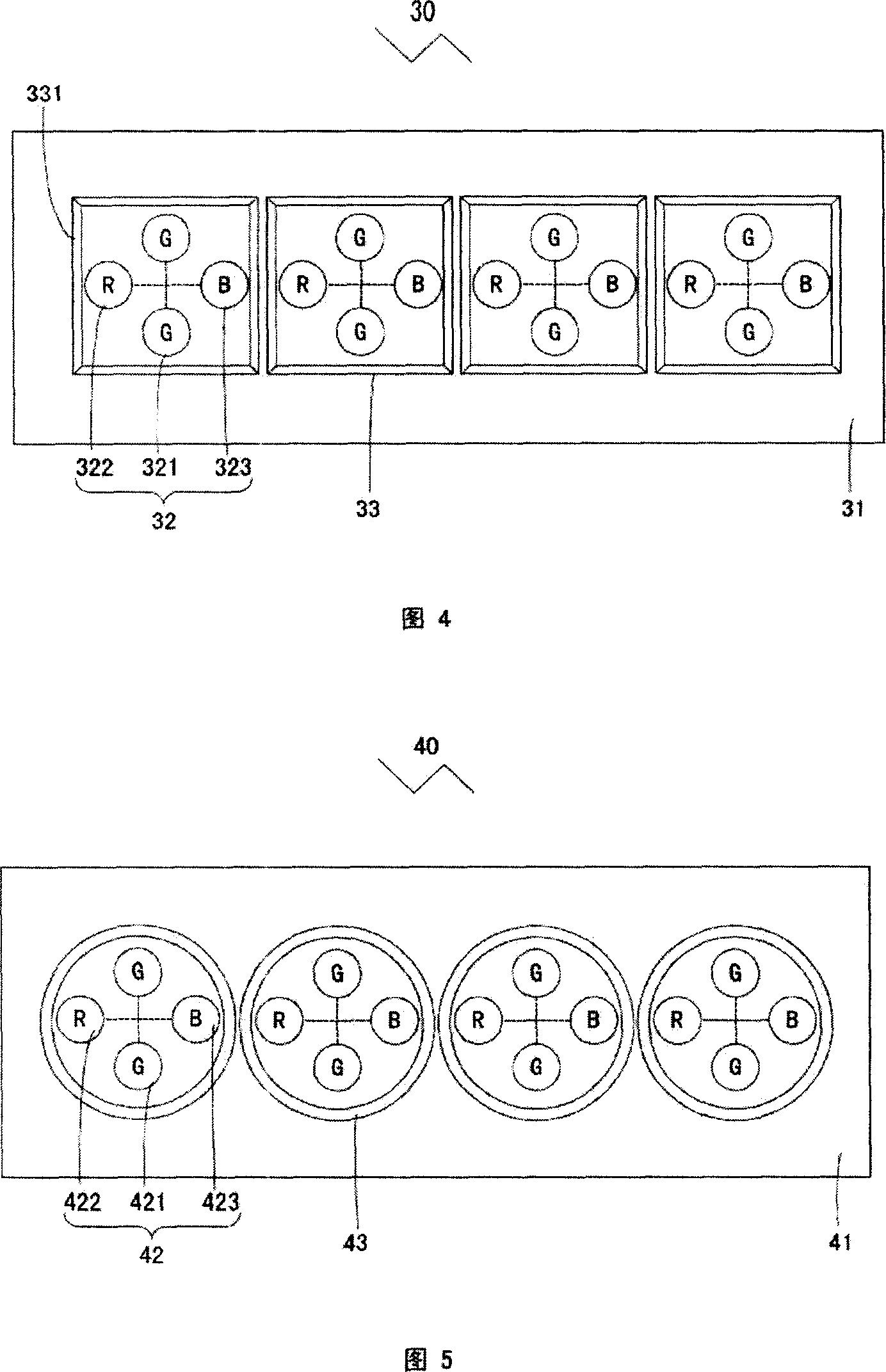

[0019] The light-emitting diode module and the backlight using the light-emitting diode module will be further described in detail below with reference to the drawings and embodiments.

[0020] Please refer to FIG. 2 , which is a schematic structural diagram of a preferred embodiment 1 of the LED module of the present invention. The LED module 10 includes a substrate 11 and four light emitting units 12 formed on the surface of the substrate 11 . The substrate 11 can be an aluminum substrate, and its shape can be determined according to the use environment. In this embodiment, the aluminum substrate is long. Each light emitting unit 12 includes two first light emitting diodes 121 , one second light emitting diode 122 and one third light emitting diode 123 . The first light-emitting diode 121, the second light-emitting diode 122 and the third light-emitting diode 123 can be selected in different colors, which are mainly determined according to the light color that the module 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com