Light-mixed layer and method for mixing lights

A light mixing layer and light source technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of low brightness and poor effect, and achieve the effect of reducing light consumption and good light mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

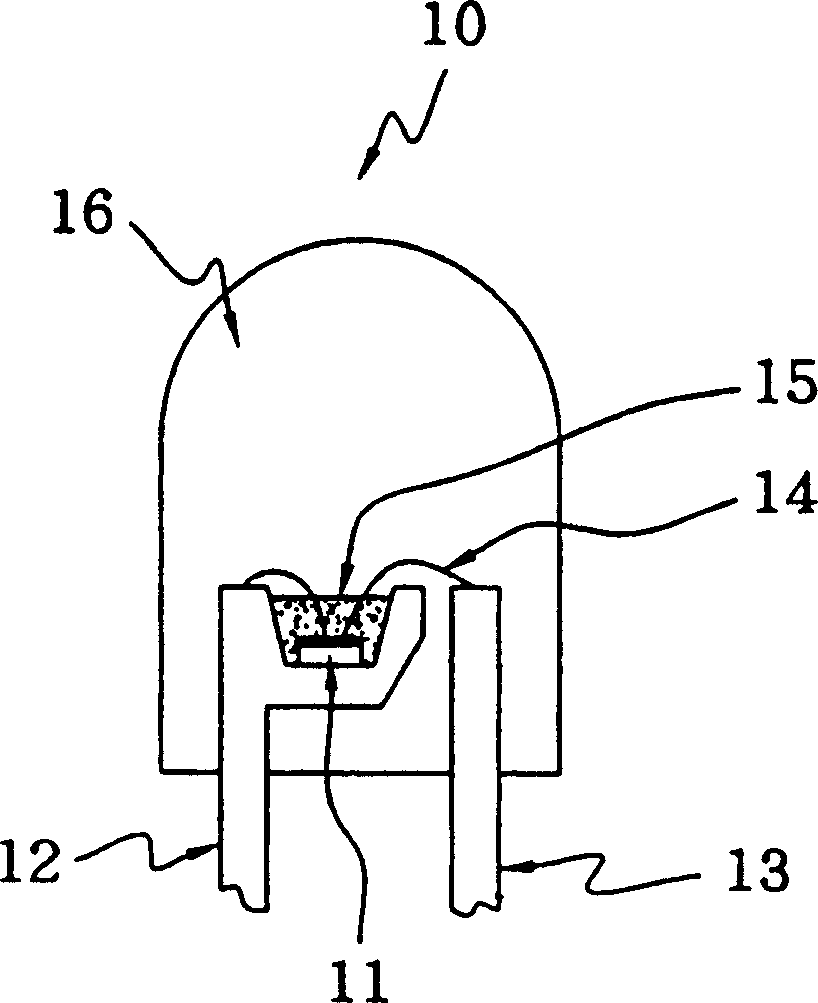

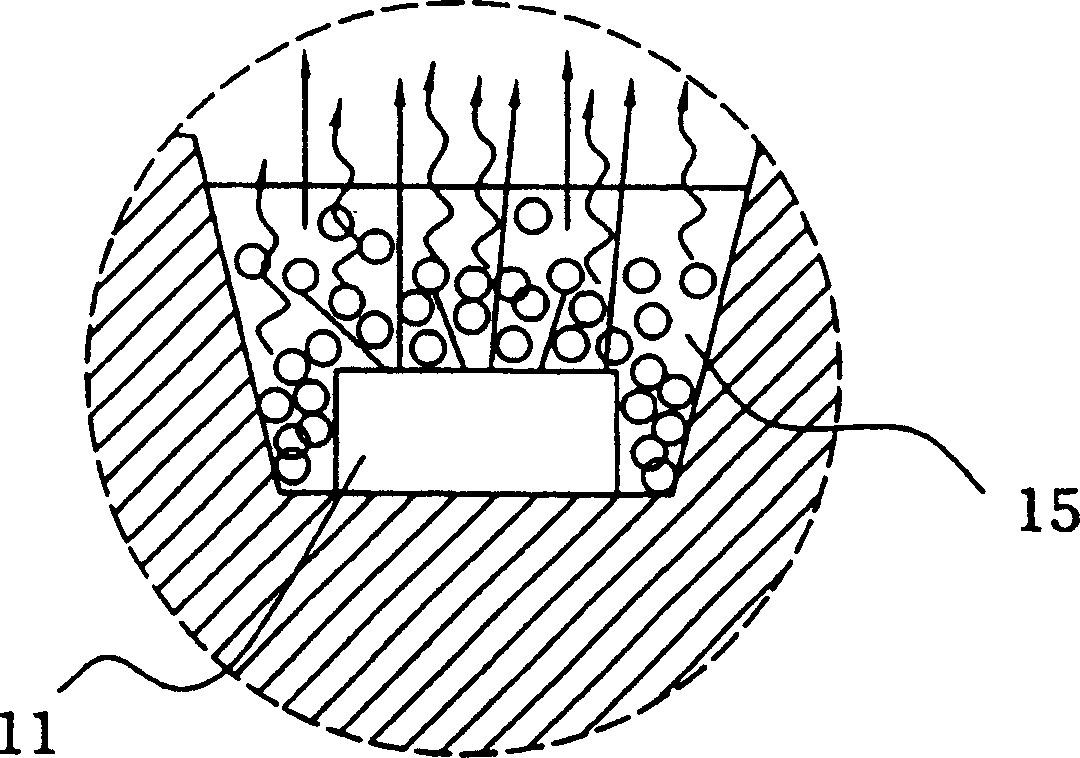

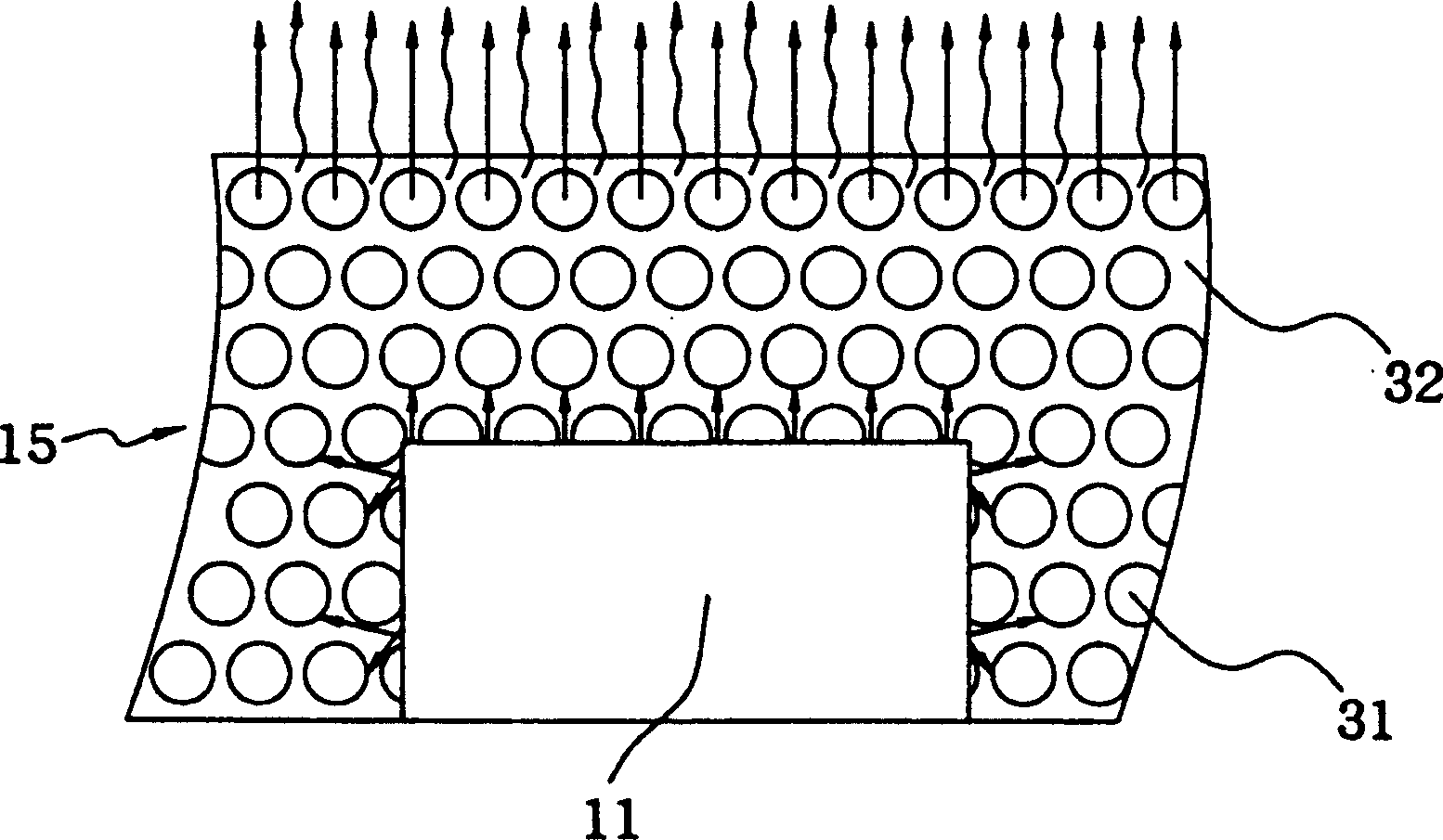

[0034] see Image 6 One embodiment of the light-mixing layer 61 of the present invention is set in the crystal cup 63, and can cover the light-emitting diode chip 62 by mixing with resin or coating, the purpose of which is to make the light-mixing layer 61 completely The light source emitted by the LED chip 62 is absorbed. The light mixing layer 61 is composed of scatterer particles 64, phosphor particles 65 and diffuser particles 66. The scatterer particles 64 can be made of quartz, glass or other polymer light-transmitting materials. The phosphor particles 65 can be selected Phosphor particles, the diffuser particles 66 can be made of barium titanyl oxide, titanium oxide, or silicon oxide. After heating and baking or UV ultraviolet irradiation, the scatterer particles 64, phosphor particles 65, and diffuser particles 66 will be able to use the gravity sedimentation method, telecentric sedimentation method, penetrating force method, pressurization method, and coagulation met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com