A kind of preparation method of black translucent amorphous niobium pentoxide

A niobium pentoxide and amorphous technology, which is applied in the field of high-pressure preparation of functional materials, can solve problems such as difficulties, and achieve the effect of easy operation, simple operation process and good amorphous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides a preparation method of black transparent amorphous niobium pentoxide, which comprises the following steps:

[0033] The monoclinic H-Nb 2 O 5 Press to 21.3~30.0GPa to obtain black transparent amorphous niobium pentoxide.

[0034] In the present invention, the monoclinic H-Nb 2 O 5 The purity is preferably greater than 99.9985%; the monoclinic H-Nb 2 O 5 The particle size of the powder is preferably 0.2 to 10 μm, more preferably 0.5 to 2 μm. According to the present invention, the monoclinic H-Nb 2 O 5 There is no special limitation on the source of, and it is sufficient to use commercially available products well known to those skilled in the art or products made by conventional technical means; in the embodiment of the present invention, it is preferably the monoclinic H-Nb produced by Alpha Company 2 O 5 .

[0035] In the present invention, the pressurized pressure is preferably 21.3 to 30.0 GPa, more preferably 23.0 to 25.6 GPa. The present ...

Embodiment 1

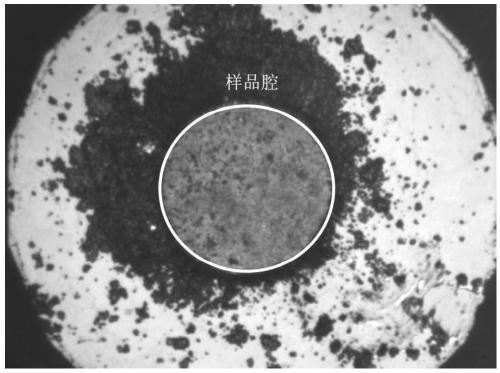

[0055] Pre-press T301 steel sheet (approximately 0.25mm×10mm×10mm) with an anvil surface of 400μm diamond anvil press at 17.5GPa, with an indentation thickness of 55μm, and drill a hole with a diameter of 140μm in the center of the indentation. Oblique phase H-Nb 2 O 5 The original material is filled into the hole of the steel sheet. After the hole is completely filled, the hole is the sample cavity. Then add 15μm ruby microspheres as a pressure mark (check the pressure in the pressure cavity), then seal the press and apply 21.3GPa pressure , The obtained black transparent amorphous niobium pentoxide.

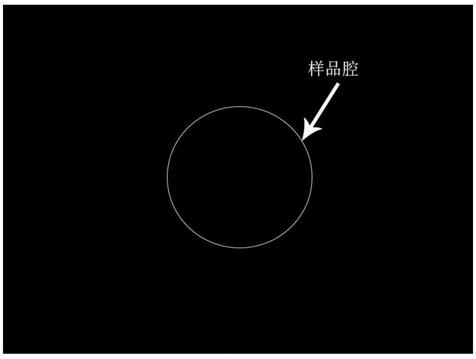

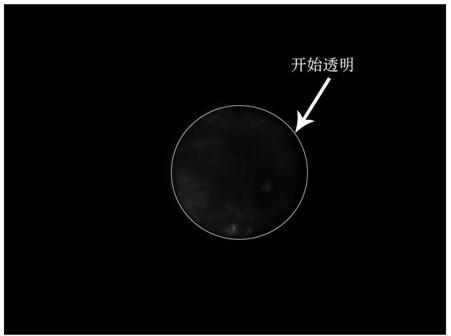

[0056] 21.3 Nb prepared under GPa pressure 2 O5, see the top light optical photo under 21.3GPa Figure 4 ,by figure 1 with Figure 4 It can be seen from the comparison that the raw material H-Nb 2 O 5 Change from white to black under 21.3GPa; see the bottom light optical photo under 21.3GPa Figure 5 ,by figure 2 with Figure 5 It can be seen from the comparison that when the pr...

Embodiment 2

[0059] Using a diamond anvil press with an anvil surface of 300 μm to pre-press T301 steel sheet at 18.5 GPa, the thickness of the indentation is 45 μm, and a hole with a diameter of 110 μm is drilled in the center of the indentation to convert the monoclinic H-Nb 2 O 5 The original material is filled into the hole of the steel sheet, and after the hole is completely filled, 10μm ruby microspheres are added as a pressure mark (to detect the pressure in the pressure cavity), and then the press is sealed, and 30 GPa is applied to obtain a black transparent amorphous five. Niobium oxide.

[0060] Nb prepared under 30.0GPa pressure 2 O 5 , See the bottom light optical photo under 30.0GPa Picture 8 ,by Picture 8 It can be seen that when the pressure reaches 30.0GPa, the produced Nb 2 O 5 Has good light transmission properties.

[0061] Press 30.0GPa to produce black light-transmitting amorphous niobium pentoxide. Relieve pressure to 0GPa, and relieve pressure to Nb under 0GPa 2 O 5 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com