Luminosity function correction glass

A vision function and glass technology, which is applied in the field of vision function correction glass, can solve problems such as the inability to meet the needs of development, and achieve the effects of improving accuracy, good visible transmission and near-infrared sharp cut-off performance

Inactive Publication Date: 2005-05-25

上海奥普玛光学玻璃有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the development of the instrumentation industry, people have higher and higher requirements for the spectral light transmission of colored optical glass, and the original glass types can no longer meet the needs of development.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] The visual function correction glass is characterized in that the formula is as follows, by weight percentage:

[0015] Phosphorus pentoxide 65.0 Sodium oxide 3.0 Potassium oxide 3.0

[0016] Lithium oxide 3.0 Aluminum oxide 10.0 Stilbium oxide 5.0

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

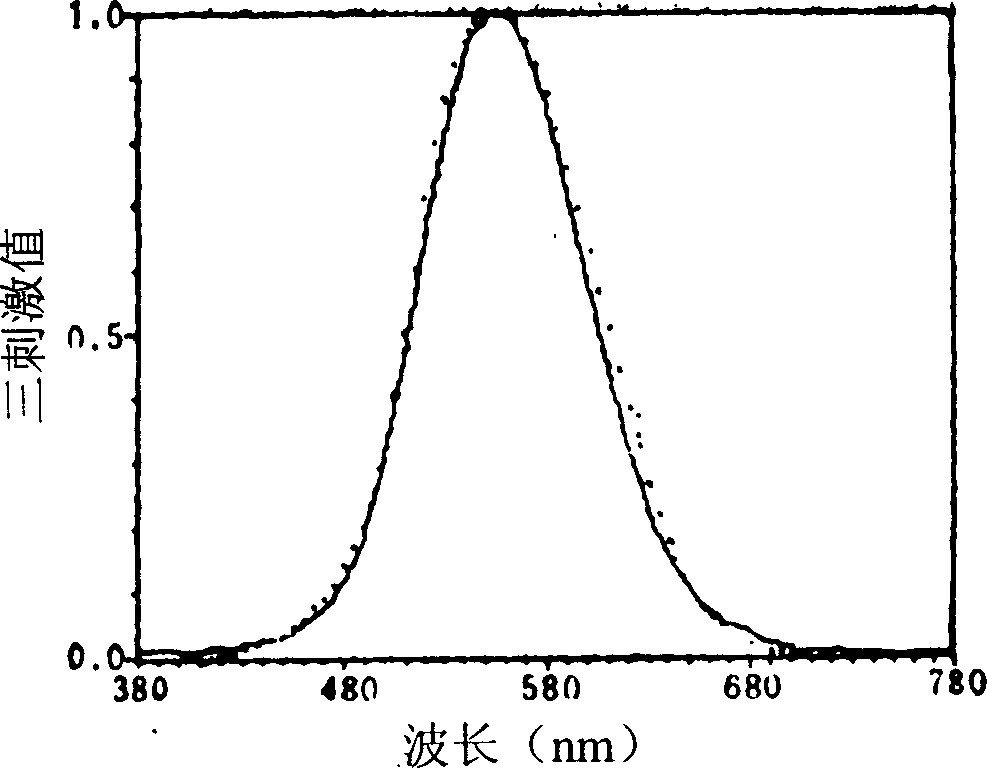

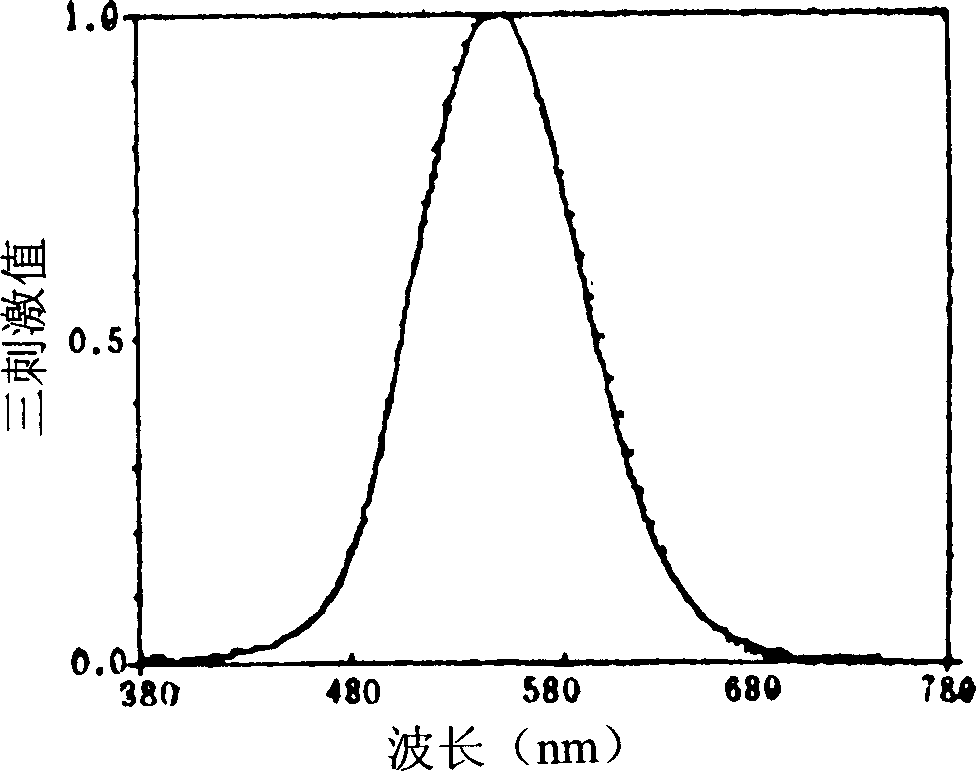

A vision function correcting glass is proportionally prepared from P2O5, sodium oxide, potassium oxide, lithium oxide, aluminium oxide, boron oxide, barium oxide and copper oxide. Its advantages are high cut-off performance to infrared light and high transparency to visual light. It can be used for color brightness meter and chromometer for higher correctness of measurement.

Description

technical field [0001] The invention belongs to an optical glass, in particular to a visual function correction glass. Background technique [0002] The coloring of divalent copper ions in various glass systems has been widely used in the preparation of colored optical glass. It is generally believed that in phosphate-based glasses, due to the pentavalent phosphorus ions on [CuO 6 ] The role and influence of oxygen ions in the coordination, so that [CuO 6 ] to form an uneven structure, resulting in the coloring of divalent copper ions as blue-green. With the development of the instrumentation industry, people have higher and higher requirements for the spectral light transmission of colored optical glass, and the original glass types can no longer meet the needs of development. Contents of the invention [0003] The present invention provides a kind of new visual function correction glass, and its formula is, percentage by weight: [0004] Phosphorus pentoxide 60.0~65....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C3/091C03C3/097C03C4/00C03C4/02

Inventor 何美玉

Owner 上海奥普玛光学玻璃有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com