Electro luminescence line and preparation method thereof

A technology of electroluminescent wires and luminescent substances, which is applied in the field of electroluminescent light sources, can solve the problems of limited improvement in the brightness of electroluminescent wires, increase the complexity of the structure of electroluminescent wires, and affect the overall brightness of electroluminescent wires. Achieve the effect of stable and reliable optical continuity, strong affinity and brightness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

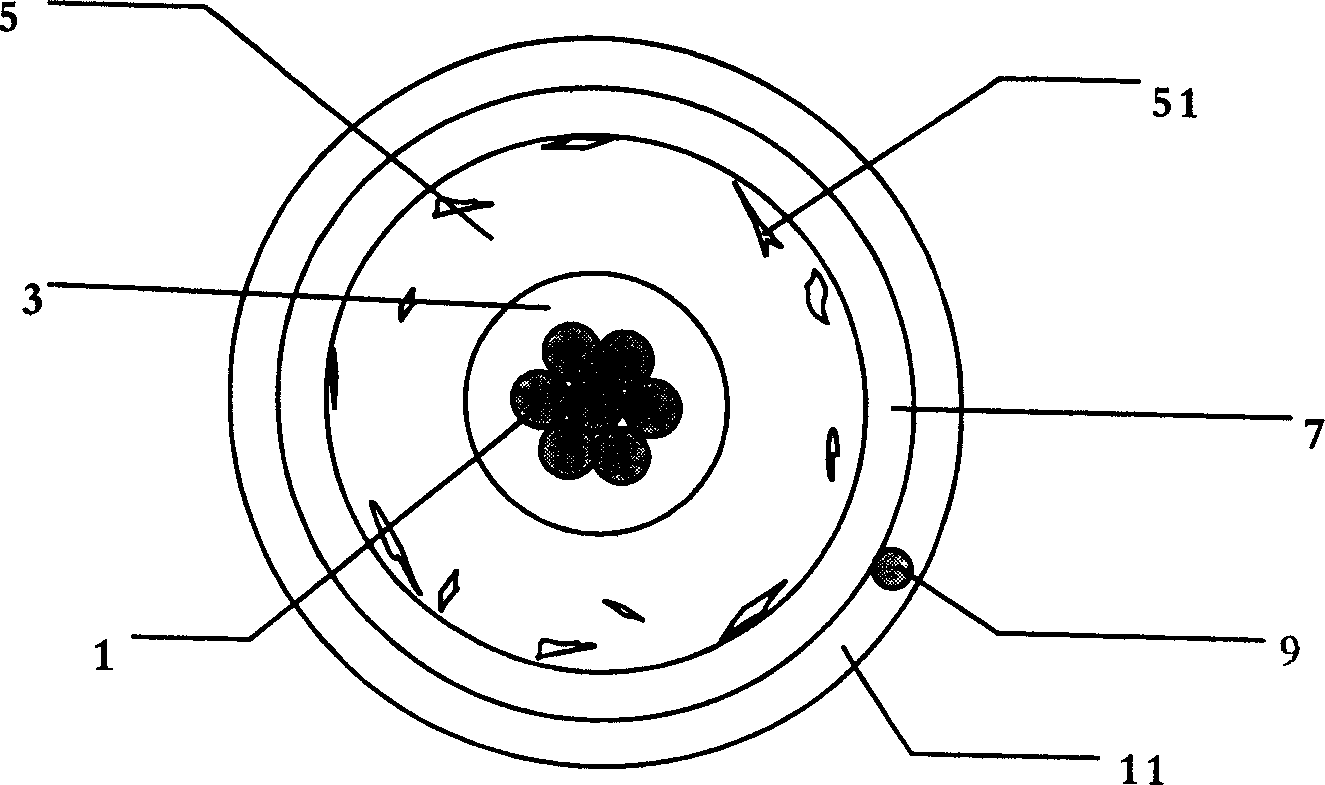

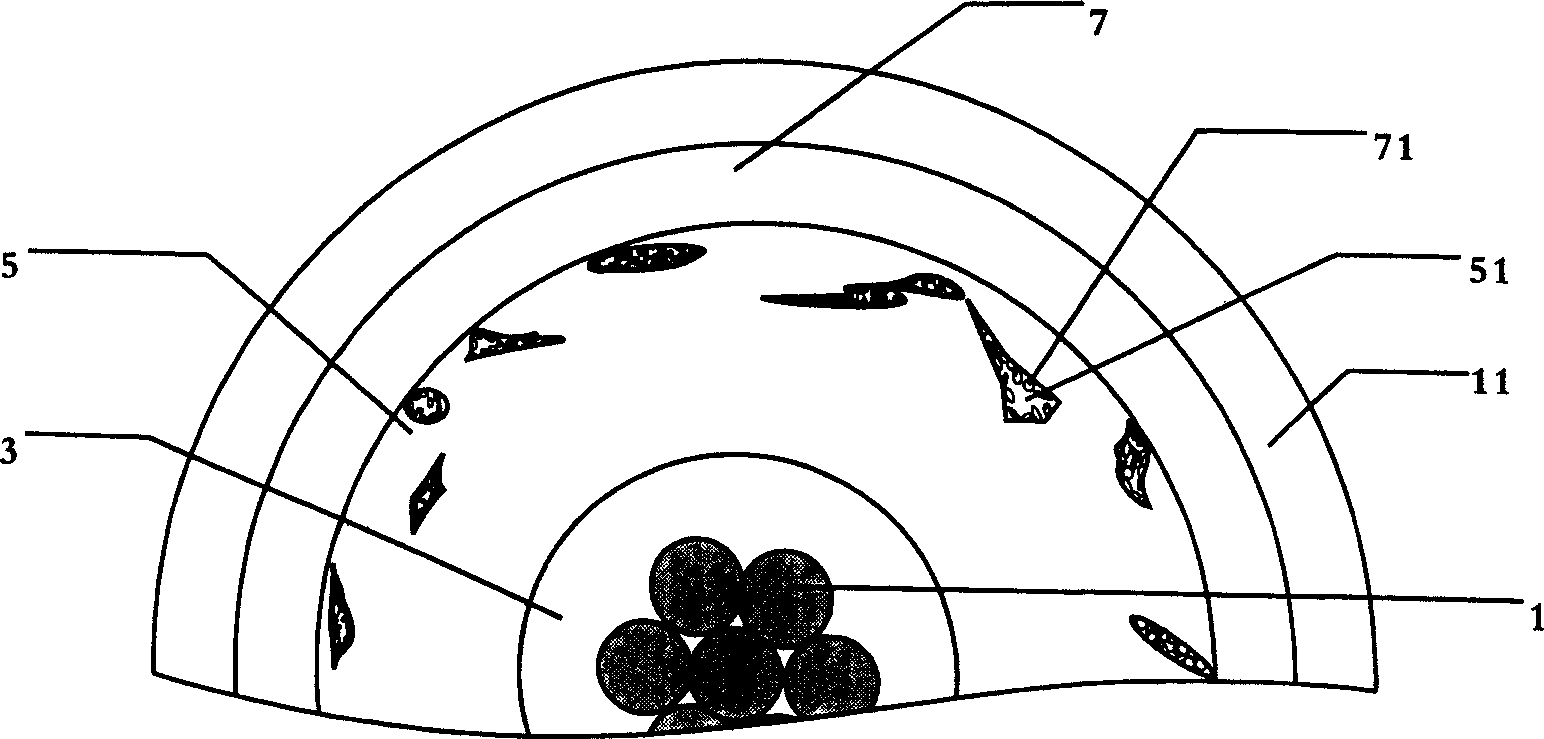

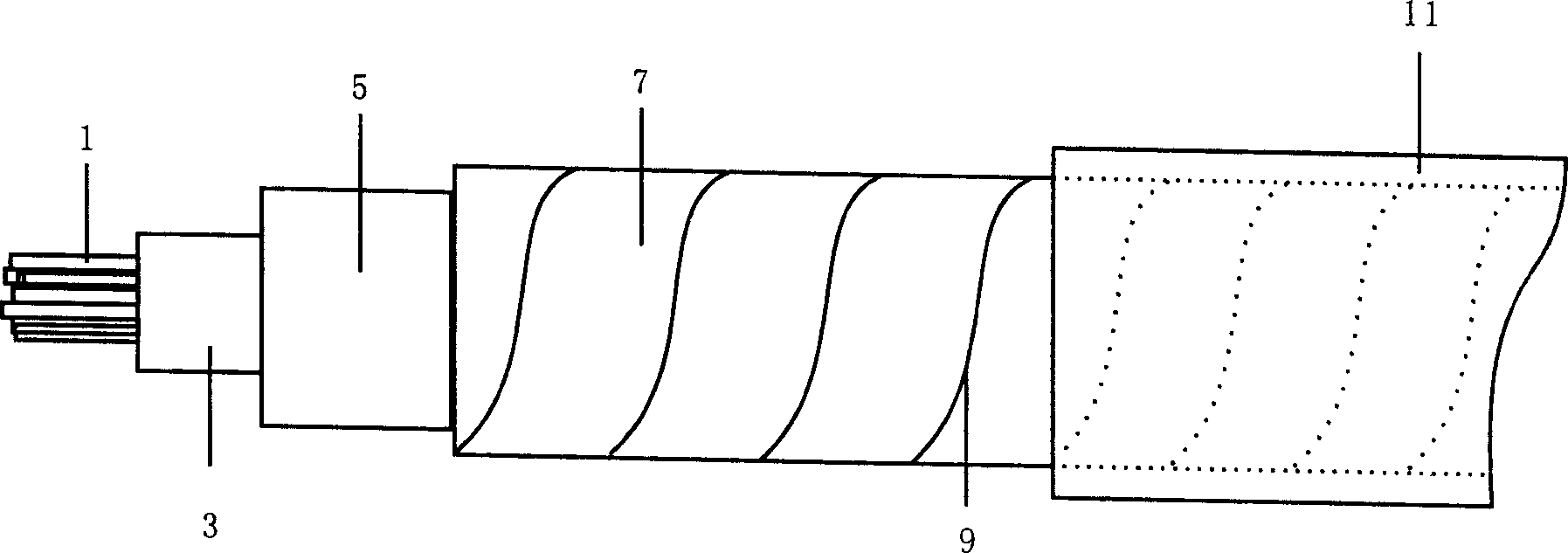

[0017] Such as Figure 1 to Figure 3 The electroluminescence wire shown has a central electrode 1 composed of multiple strands of linear conductors, and the combination of multiple strands of linear conductors has better flexibility and higher strength than single strands of linear conductors. The outer surface of the center electrode 1 is covered with an insulating medium layer 3 made of an electrical insulating material. The electrical insulating material is preferably a resin varnish mixture, which has excellent film-forming properties and electrical insulation properties, and can be made into a super The coating layer is thin and not easy to damage, so the electric field of the luminous line can be permanently balanced to ensure the continuous and stable emitted light. The outer surface of the insulating medium layer 3 is covered with a lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com