Method of utilizing biological function to prepare high-elasticity conductive polymer silk

A technology of conductive polymers and high elasticity, which is applied in the manufacture, application, and animal feed of conductive/antistatic filaments. It can solve problems such as adverse effects on silk performance and decreased silk elasticity, and achieves easy biological digestion and absorption and low production costs. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of Conductive Polymer Aqueous Solution

[0023] (1) Add 4 g of polyaniline and 100 ml of water into a beaker, place in a cell pulverizer for ultrasonic dispersion, the reaction temperature is 25 degrees Celsius, and the reaction time is 2 hours;

[0024] (2) Cool naturally to room temperature after the reaction, and filter the dispersed product under reduced pressure to obtain a polyaniline dispersion solution with a relatively uniform particle size.

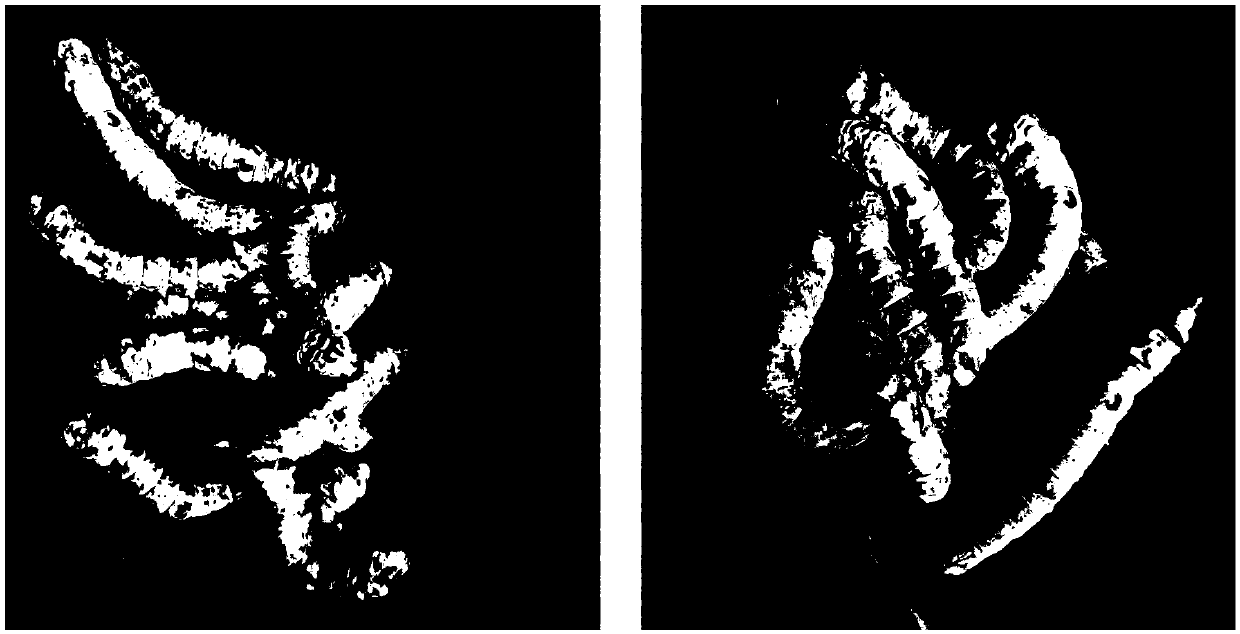

[0025] 2. Apply the above-mentioned conductive polymer aqueous solution to mulberry leaves by spraying to obtain conductive feed; use the above-mentioned feed to feed silkworms, and manufacture silk composite materials with high-elastic conductive polymers by spinning silkworms.

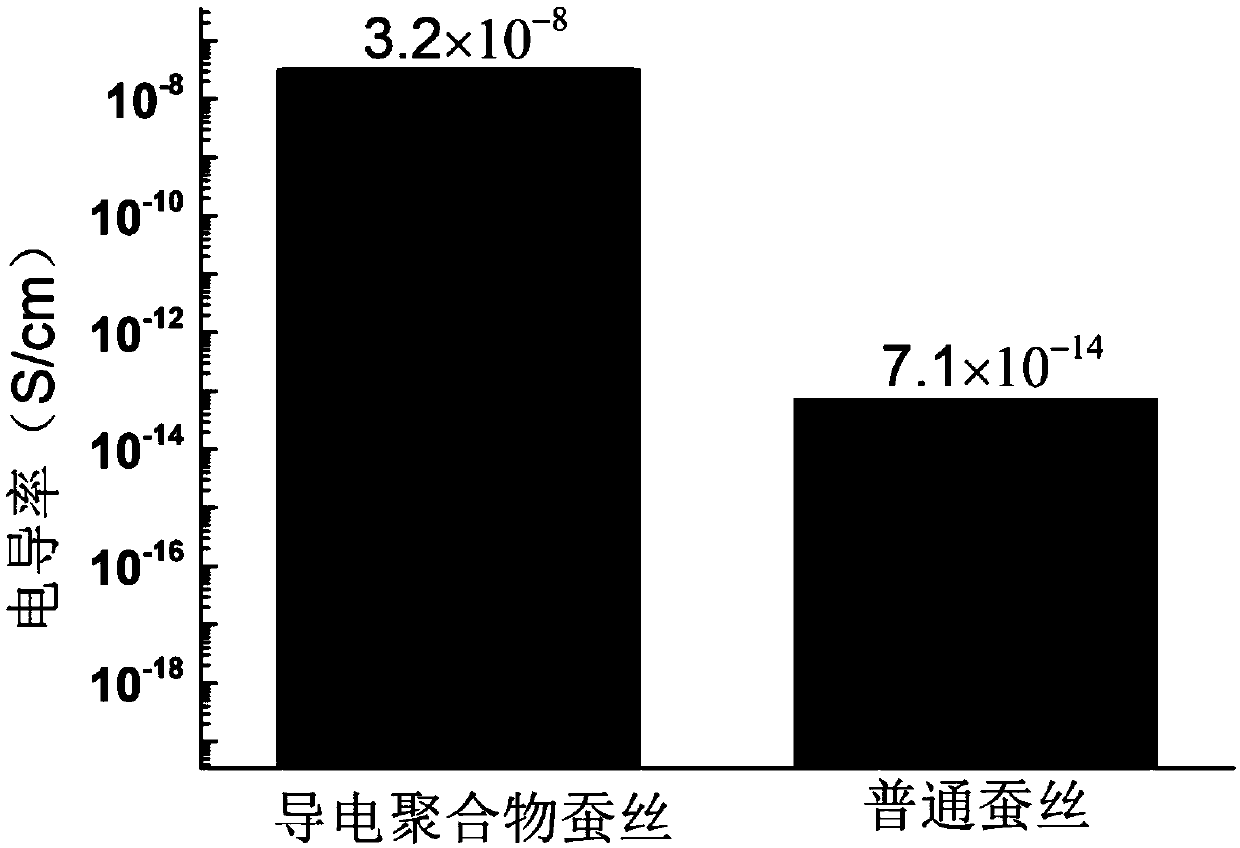

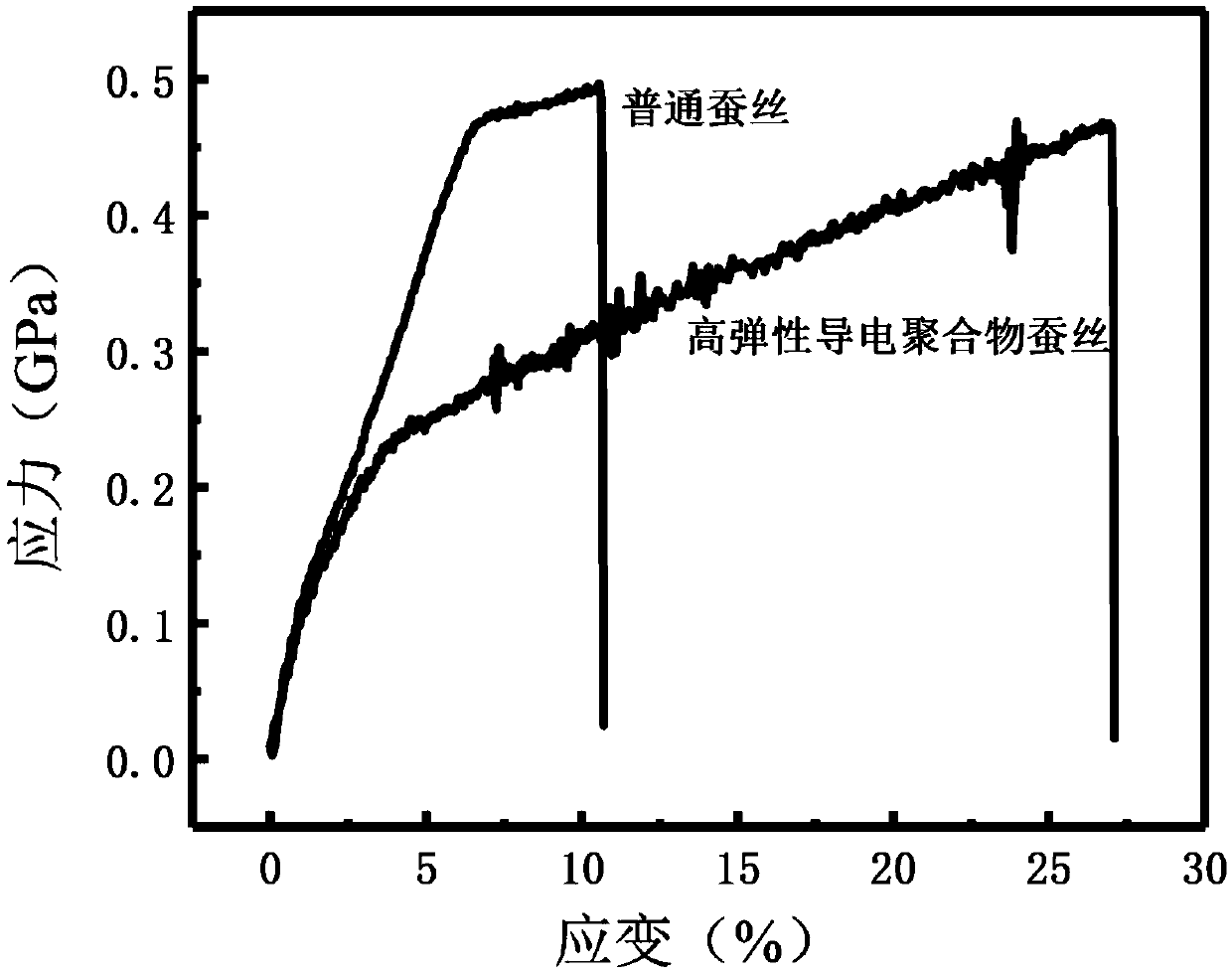

[0026] The highly elastic conductive polymer silk composite material obtained by the above method has an electrical conductivity of 3.2×10 - 8 S / cm, compared to the conductivity of ordinary silk 7.1×10 -14 S / cm conductivity has...

Embodiment 2

[0028] 1. Preparation of conductive polymer aqueous solution:

[0029] (1) Add 4 g of polythiophene and 100 ml of water into a beaker, place them in a cell pulverizer for ultrasonic dispersion, the reaction temperature is 25 degrees Celsius, and the reaction time is 2 hours;

[0030] (2) Naturally cool to room temperature after the reaction, and filter the dispersed product under reduced pressure to obtain a polythiophene dispersion solution with a relatively uniform particle size.

[0031] 2. Apply the above-mentioned conductive polymer aqueous solution to mulberry leaves by spraying to obtain conductive feed; use the above-mentioned feed to feed silkworms, and manufacture silk composite materials with high-elastic conductive polymers by spinning silkworms.

[0032] The highly elastic conductive polymer silk composite material obtained by the above method has an electrical conductivity of 8.7×10 - 8 S / cm, the electrical conductivity has been significantly improved. In addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com