Light-emitting device and manufacturing method thereof

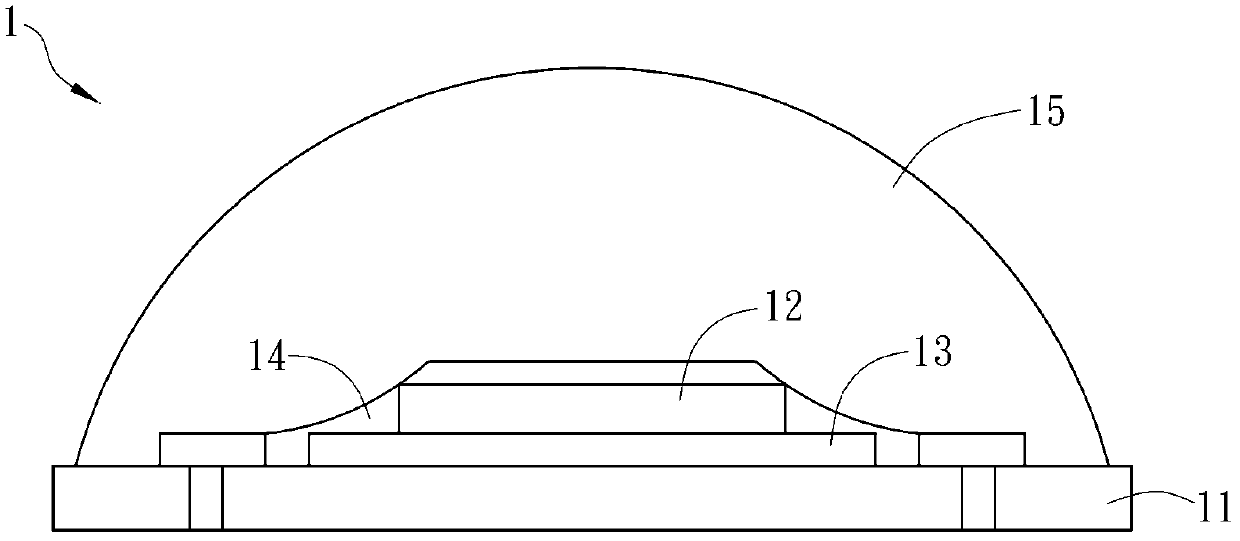

A technology for a light emitting device and a manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the uniformity and consistency of optical color performance, poor characteristics, and inability to uniformly mix light in a light emitting device 1, and achieve Solve the effects of poor color uniformity and consistency, good color uniformity and consistency, and good optical mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A light emitting device and its manufacturing method according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

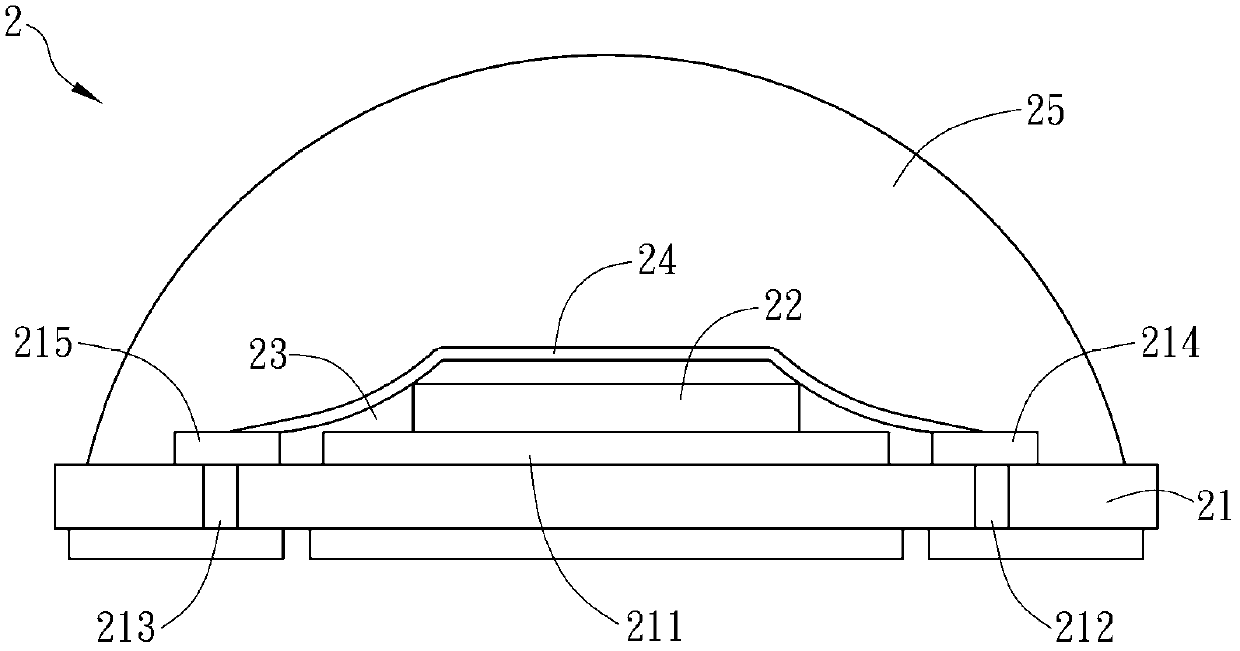

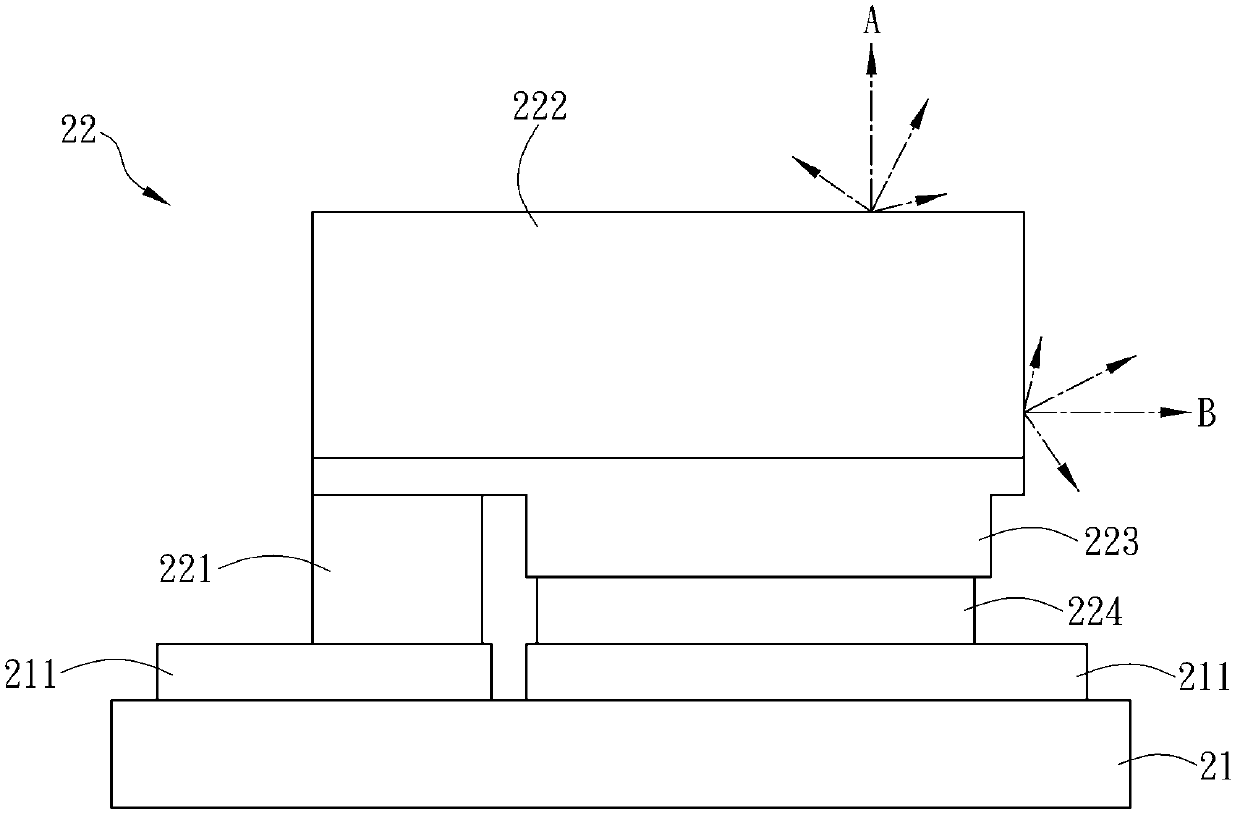

[0038] Please refer to figure 2 , which is a schematic diagram of a light emitting device according to a preferred embodiment of the present invention. The light emitting device 2 includes a substrate 21 , an LED die 22 , a first transparent layer 23 , a wavelength conversion layer 24 and a second transparent layer 25 . Wherein the substrate 21 has a die bonding portion 211, which is located at the center of the upper surface of the substrate 21, the LED die 22 is disposed on the die bonding portion 211, and the first transparent layer 23 covers the side of the LED die 22 and above, the light wavelength conversion layer 24 covers the first light transmission layer 23 with a uniform thickness, and the second light transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com