Fuel tank inlet device

A technology of injection device and fuel tank, which is applied in the direction of power unit, transportation and packaging, and the arrangement combined with the fuel supply of internal combustion engines, etc., can solve problems such as backflow, and achieve the effect of preventing fuel theft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

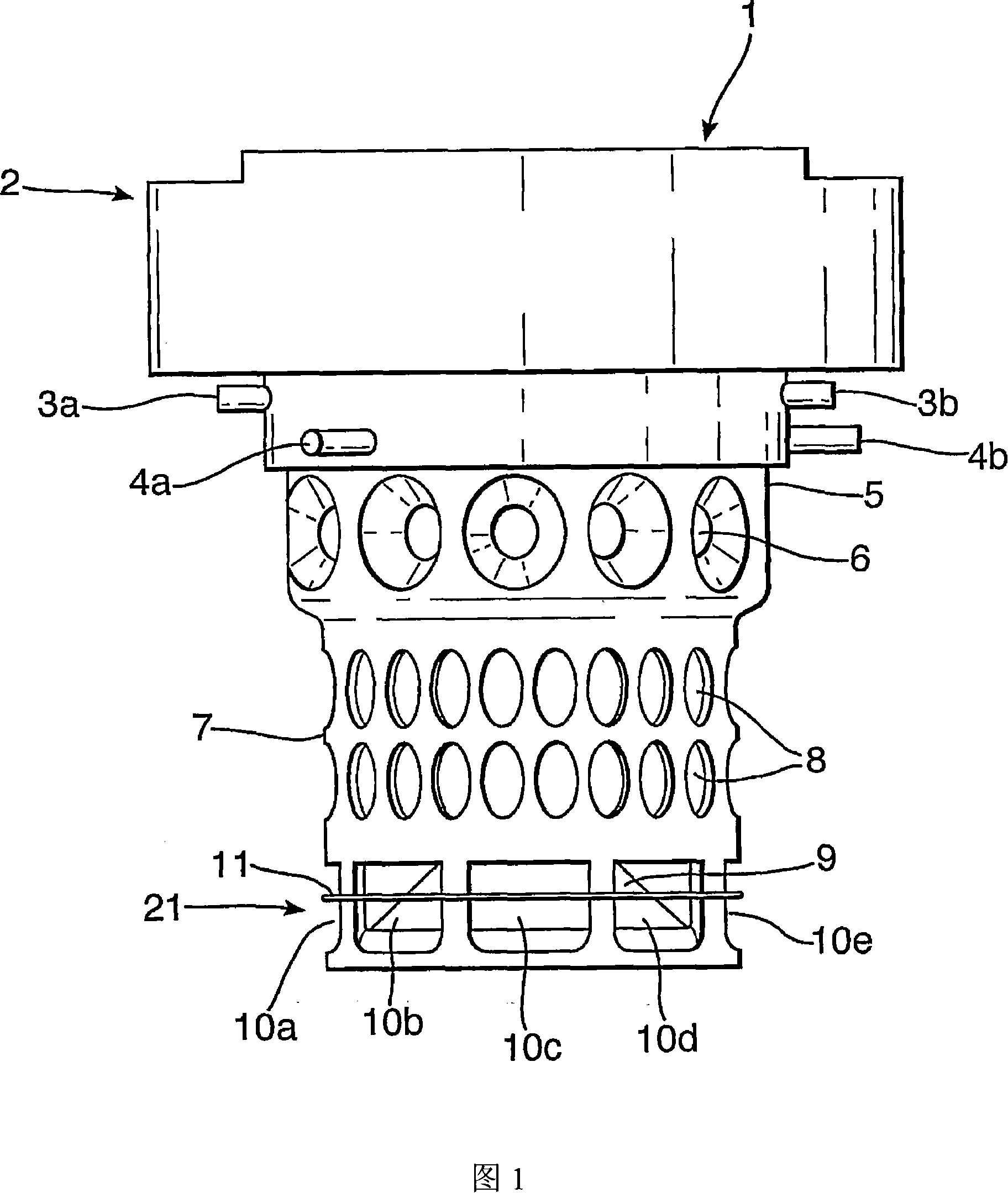

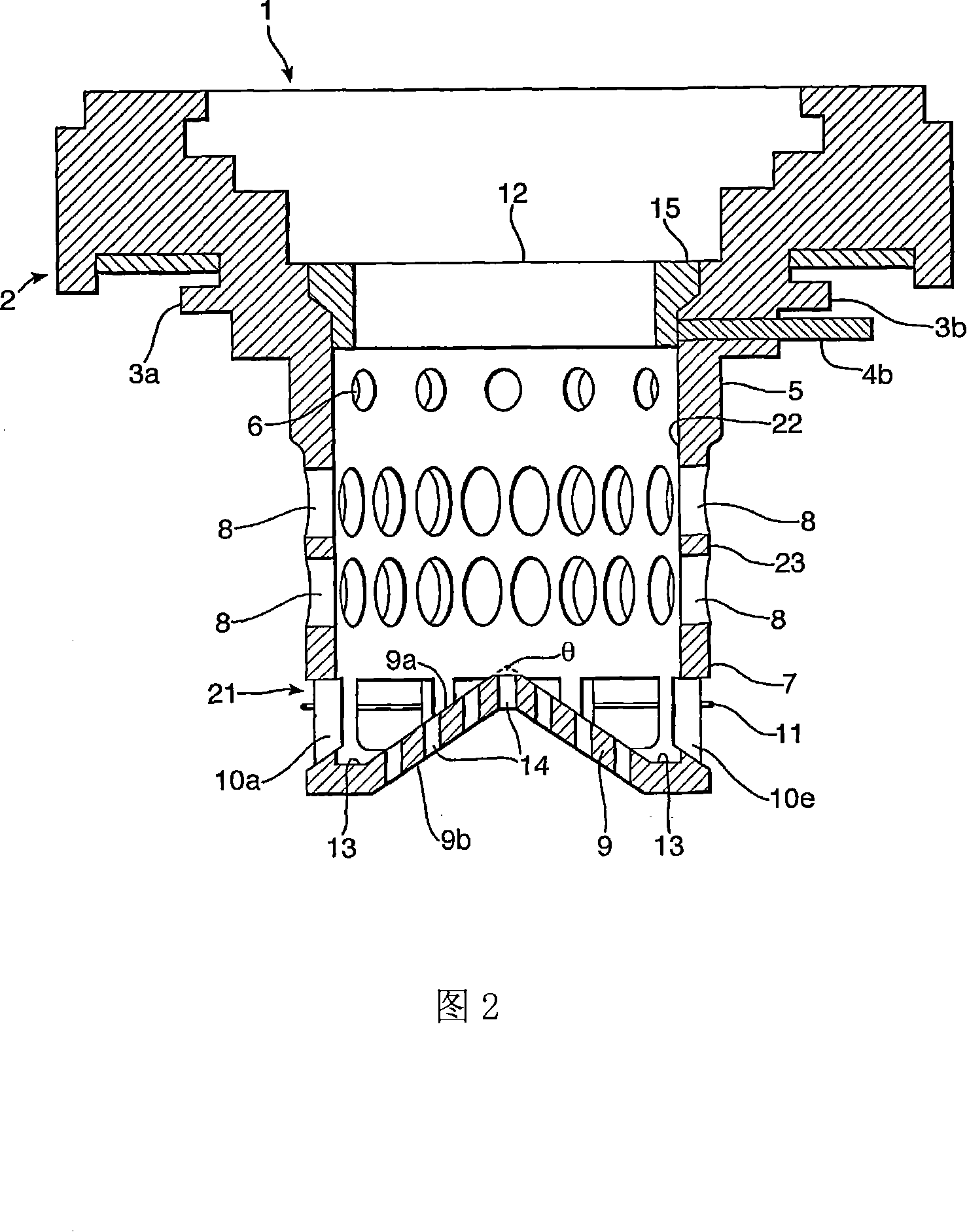

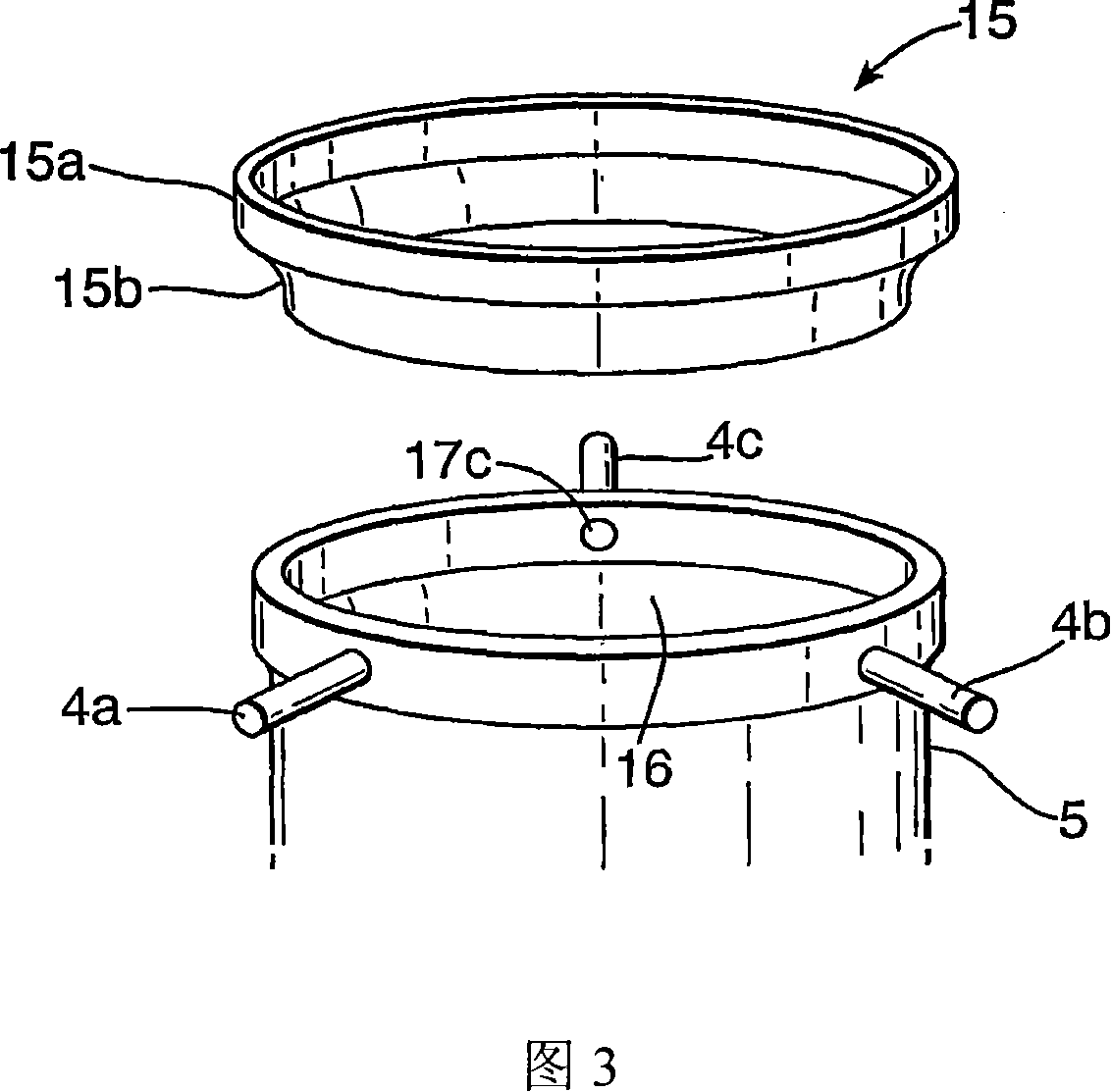

[0085]1 and 2 are a side view and a schematic cross-sectional view, respectively, of a fuel tank filling device in a preferred embodiment of the present invention in which the inner surface of the end portion has a conical portion to direct fuel flow towards the side wall. The fuel tank filling device is marked 1 in the figure, and it can prevent the liquid fuel in the fuel tank equipped with the device from being stolen. The device 1 contains an attachment 2 which enables the device 1 to be securely connected to a fuel tank or a filler neck; a fuel injection body 5 for receiving fuel, which contains an injection port 12 for injecting fuel , also contains an output port to output fuel to the fuel tank. The fuel injection body 5 also has a side wall 7 extending from a first end of the device near or within the filler opening 12 to a further end portion 9 connected to a second end portion of the device 1 . The end portion 9 has an inner surface 9a for receiving fuel from the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com