Drum type washing machine

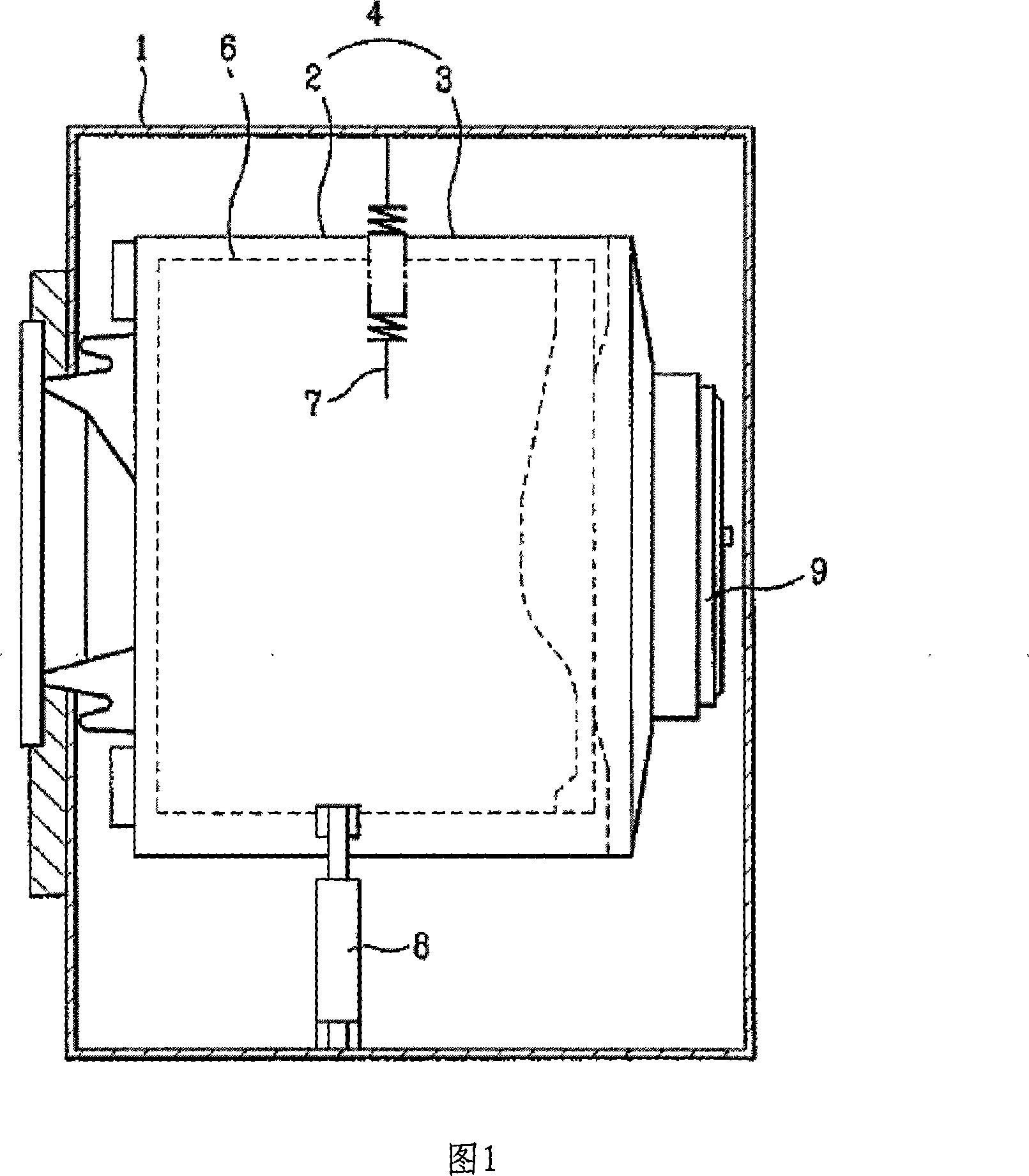

A drum washing machine, drum technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve problems such as damage, damage to the outer tub 4, and achieve the effect of increasing capacity and minimizing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings.

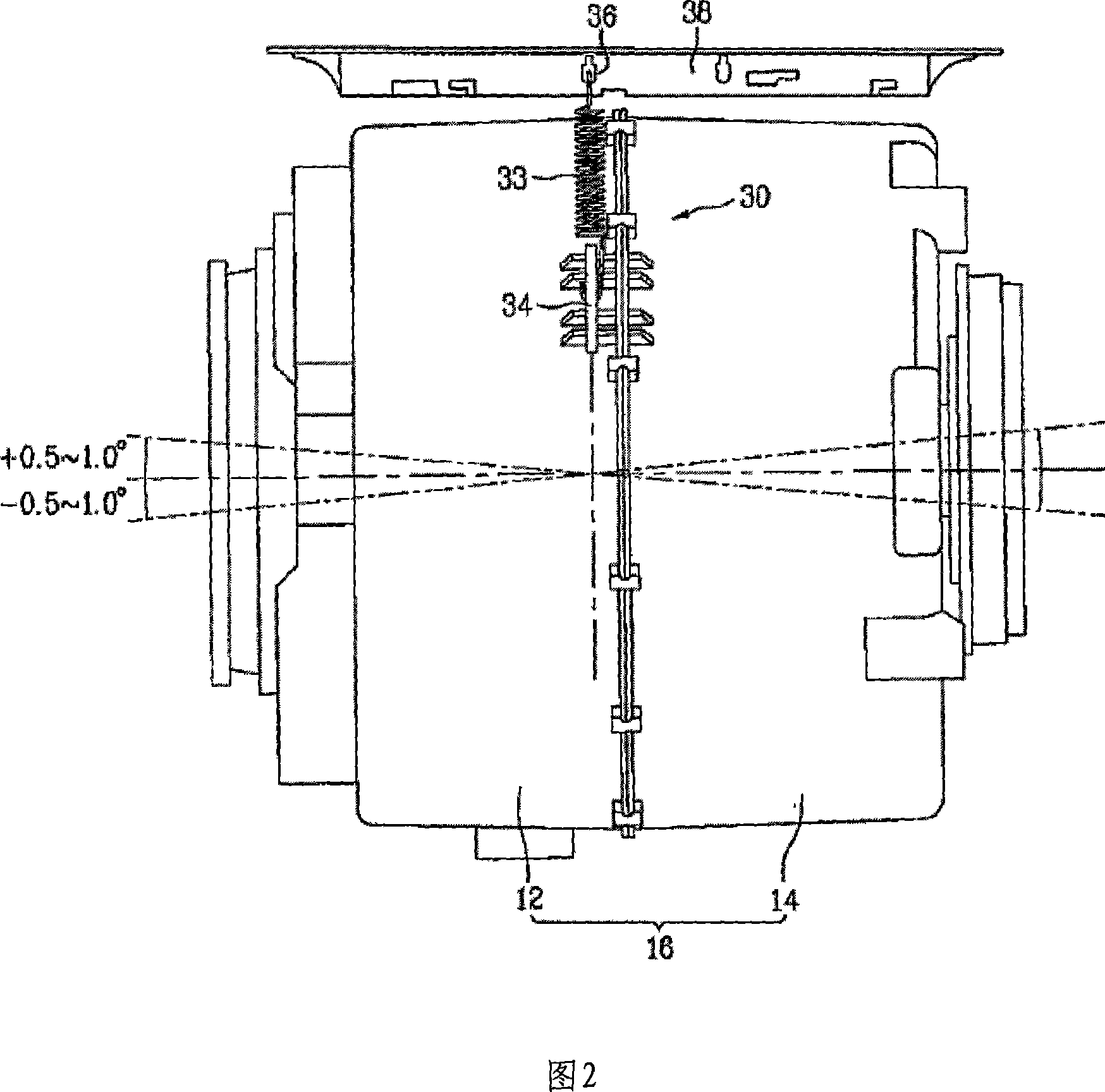

[0037] Fig. 2 is a side view of the drum with the inclination reducing device installed in the present invention.

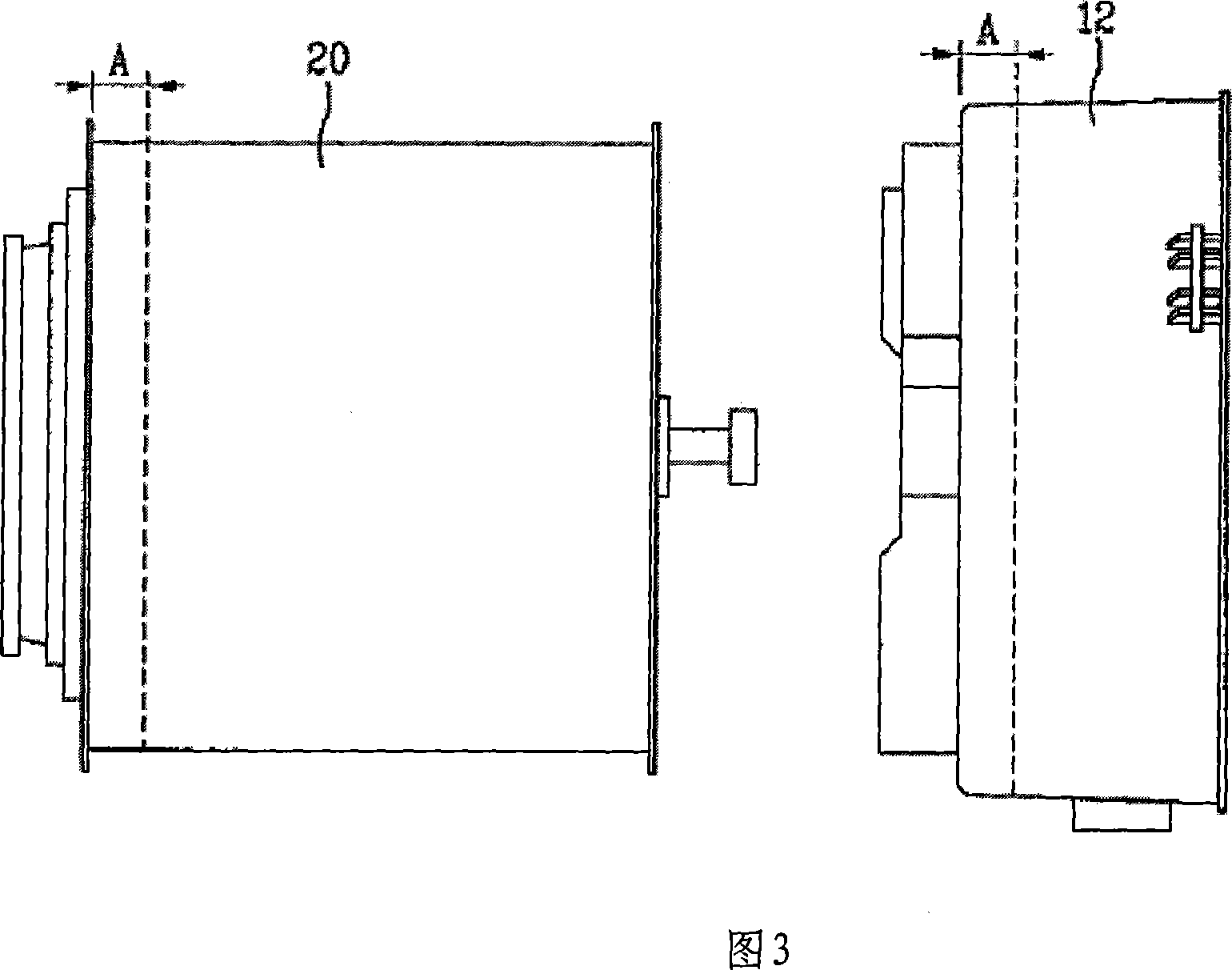

[0038] With reference to Fig. 2, drum washing machine of the present invention is equipped with reducing inclination device 30, and this inclination reducing device can reduce the entrance of outer tub and drum when washing and washing water are put into drum (referring to Fig. 3, 20). slope down.

[0039] Here, the inclination reducing device 30 includes: a double elastic device 33 with a certain distance from the center of gravity of the outer tub 16 . The outer barrel 16 can be divided into a front barrel 12 and a rear barrel 14. The double elastic device 33 is fixed on the fixing bracket 34 connected to the outside of the front barrel 12, and one end is fixed on the fixing hole of the upper fixing plate 38 on the inner side of the casing (not shown)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com