Cyclone type nozzle high-pressure blowing circuit breakers with groove

A circuit breaker and high-pressure air technology, which is applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of difficult arc blowing methods, which are not conducive to greatly improving the resistance to electric field breakdown between contacts, etc. It achieves the effect of convenient implementation, simple structure and improved breaking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

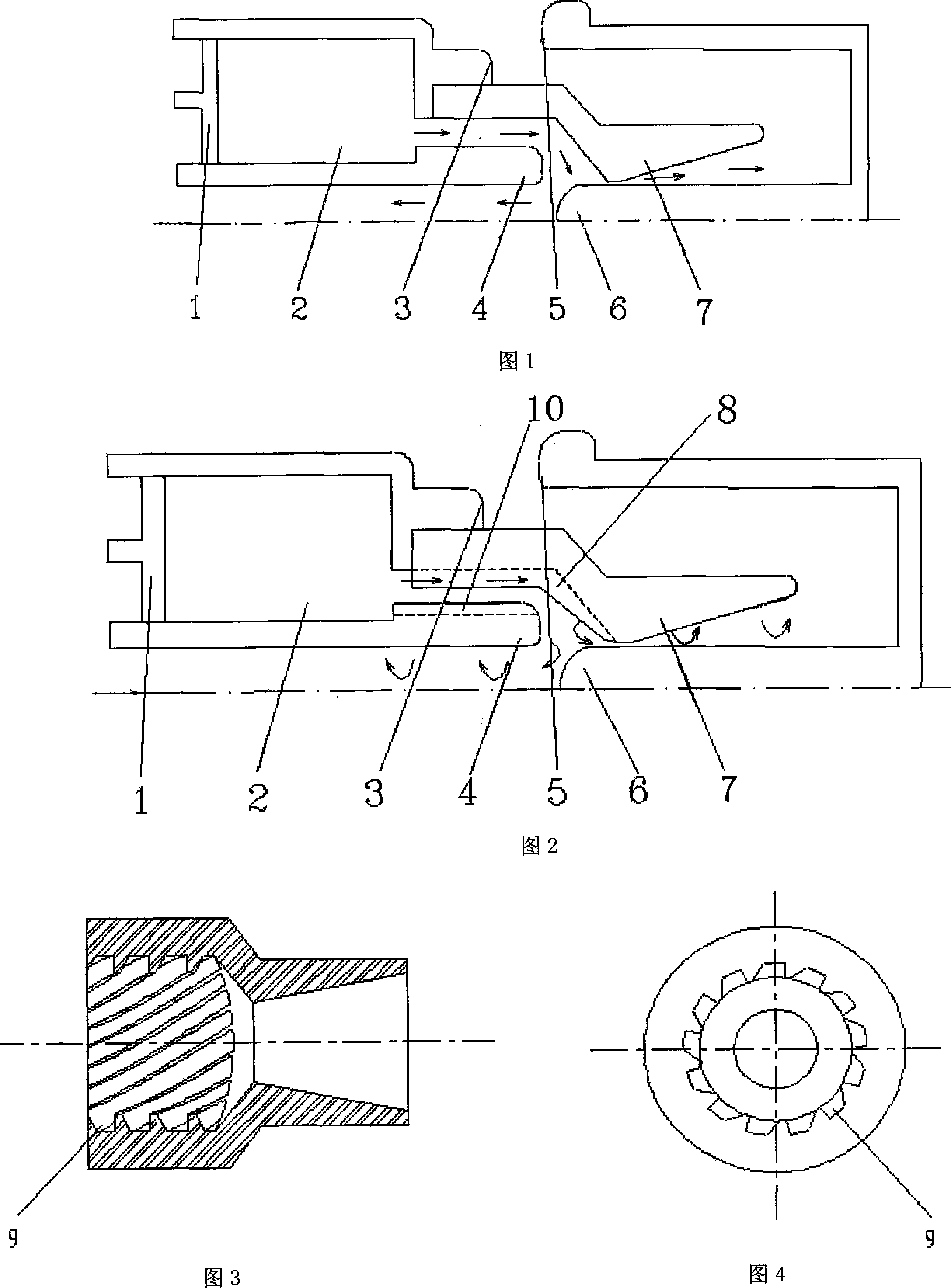

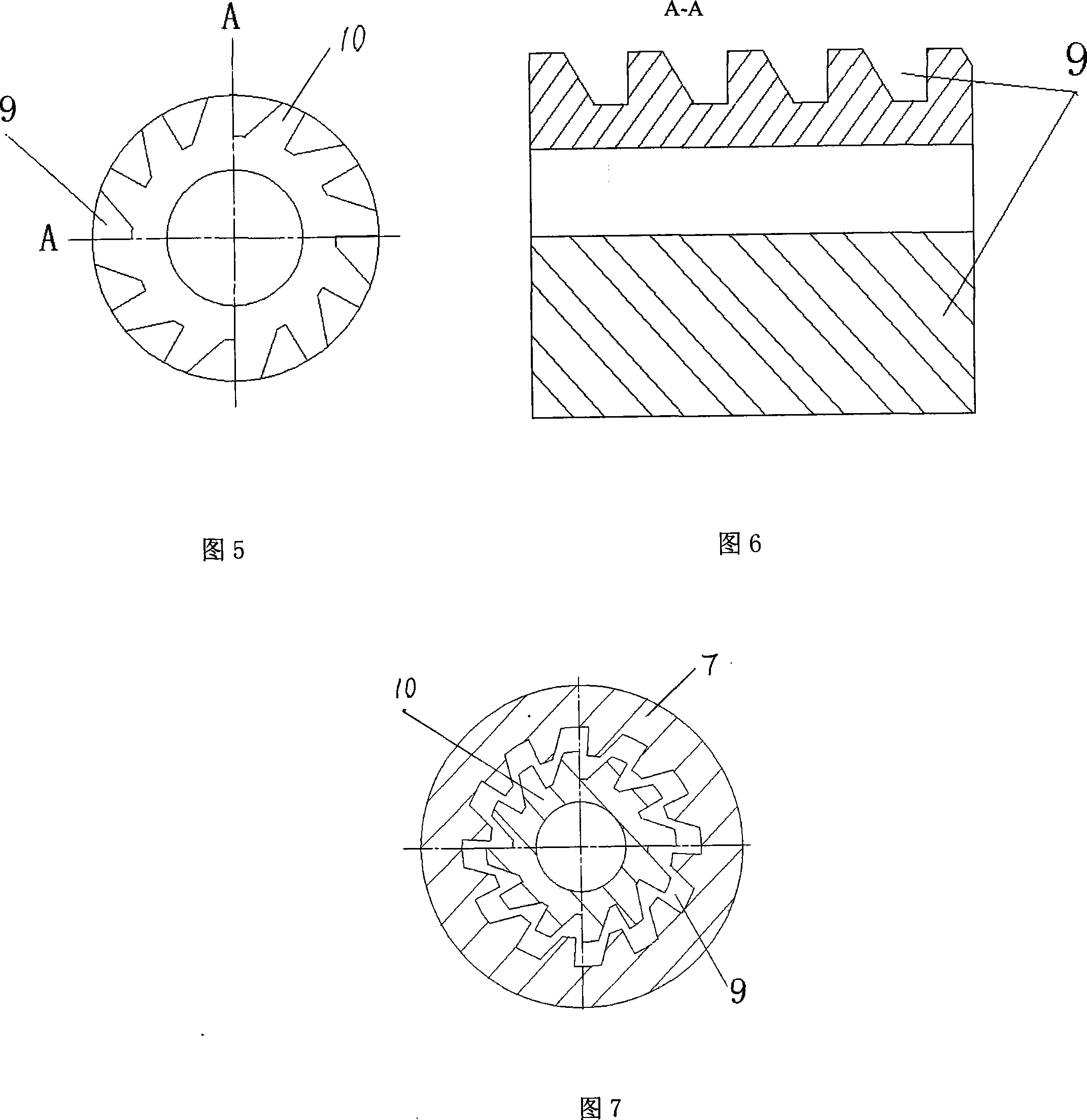

[0016] Example 1: Arrange spiral grooves evenly along the axial direction on the inner surface of the spout, as shown in Figure 4.

example 2

[0017] Example 2: Arrange spiral grooves evenly along the axial direction on the outer surface of the moving arc contact housing, as shown in Figure 5.

example 3

[0018] Example 3: Arrange spiral grooves evenly along the axial direction on the inner surface of the spout and the outer surface of the moving arc contact cover at the same time, as shown in Figure 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com