Filter assembly

A filter assembly and filter cloth technology, applied in the field of electric control boxes, can solve the problems of flow attenuation that cannot be calculated by users, danger, and poor air flow performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

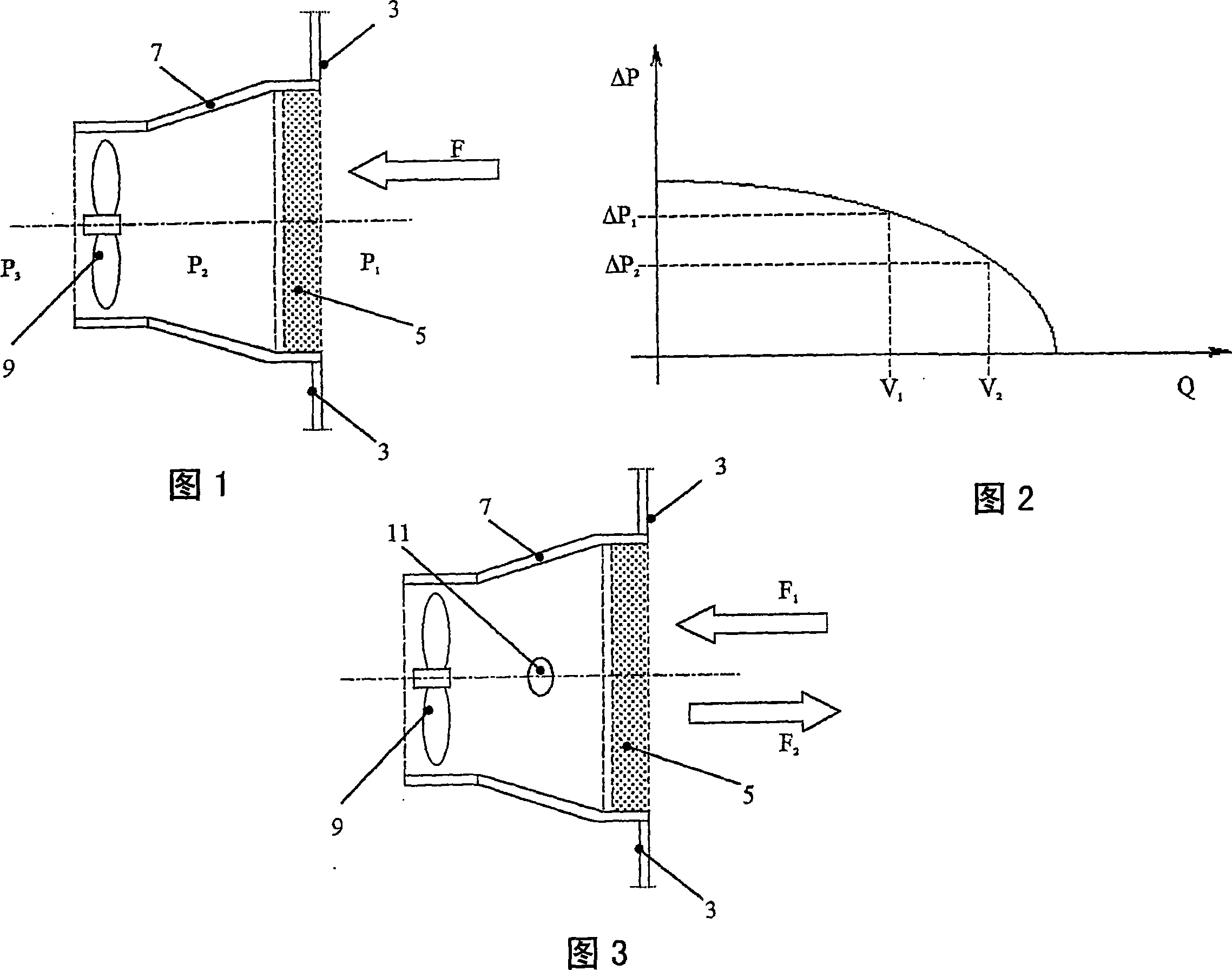

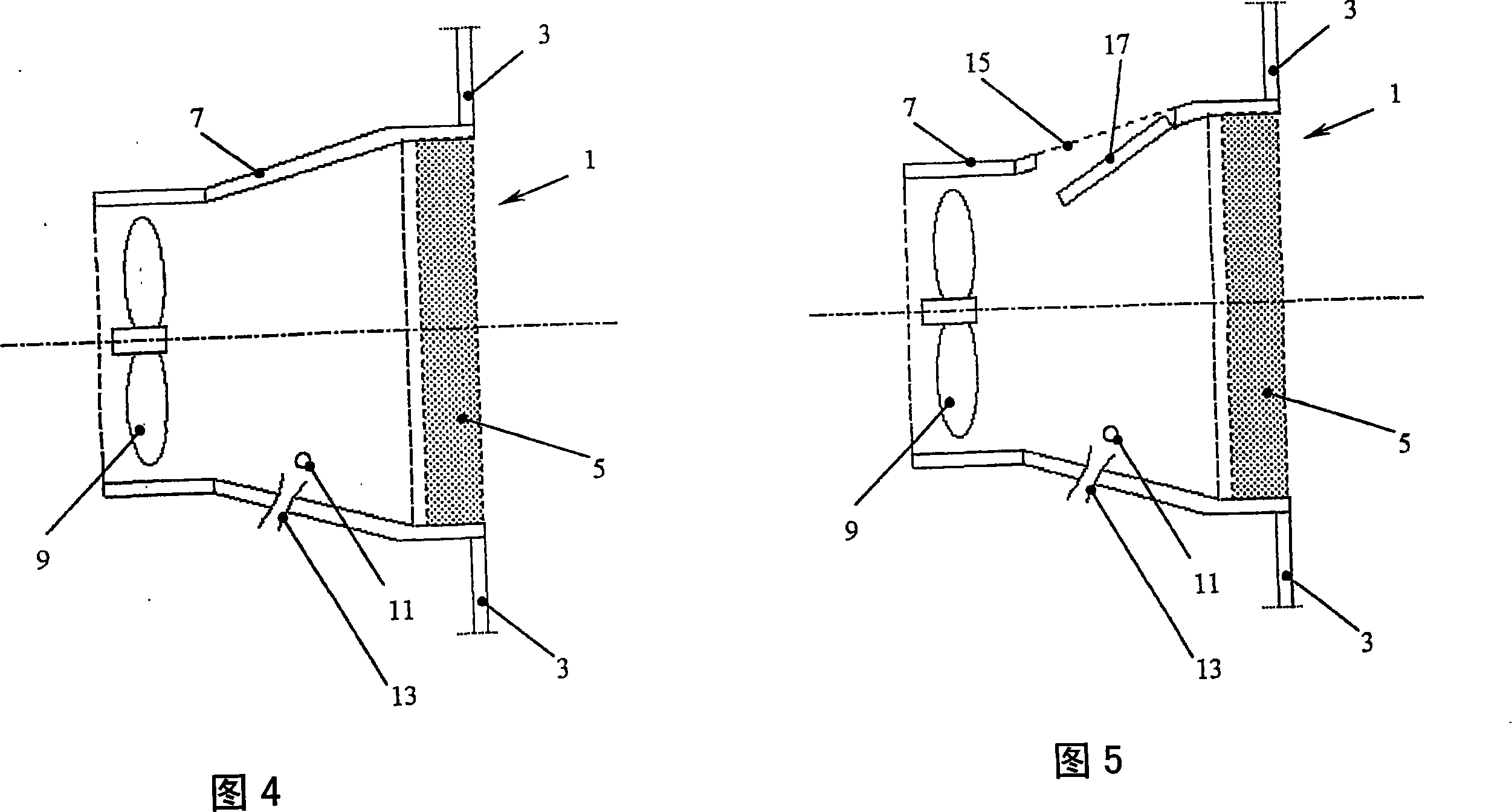

[0026] Referring to Figure 1, a prior art filter assembly for an electrical cabinet can be noted. This filter assembly is inserted into the wall 3 of the electric control box, as is known, from the outside of the box to the inside of the box in the direction of air flow F, consisting of a filter cloth 5, a delivery box 7 and a fan 9; In construction, three pressure ranges are generally defined: external pressure P1, intermediate pressure P2 between filter cloth 5 and fan 9 (equal to P1 minus filter load leakage), and internal head pressure P3 (equal to p2 minus fan prevalence). As mentioned earlier, it is clear that the fan 9 has to exceed the air passage resistance of the filter cloth 7, which occurs with load leakage which increases the pressure the fan has to overcome, subsequently degrading the performance in terms of air flow.

[0027] In order to measure the flow of air, two different modes of operation can be referred to: in the first case the flow will be measured dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com